Microporous ultra-thin soft carbon nanosheet, and preparation method and application thereof

A technology of nanosheets and soft carbon, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of large number of SEI, decreased Coulombic efficiency, and increased irreversible capacity of electrode materials, and achieve enhanced diffusion performance, increased capacity contribution, and good cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

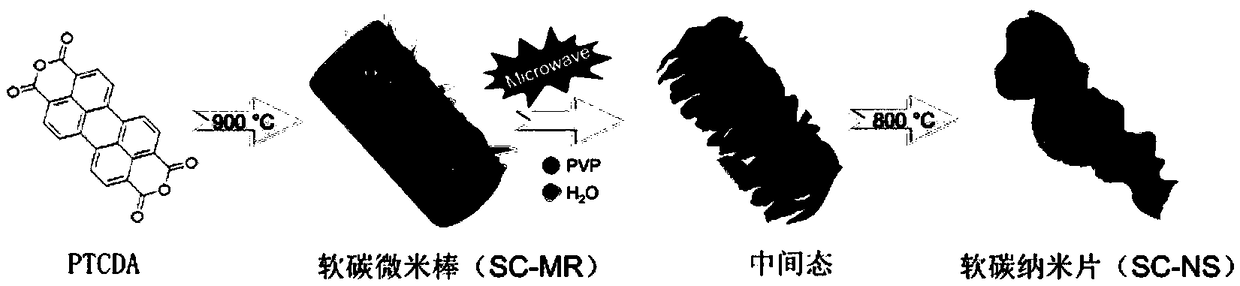

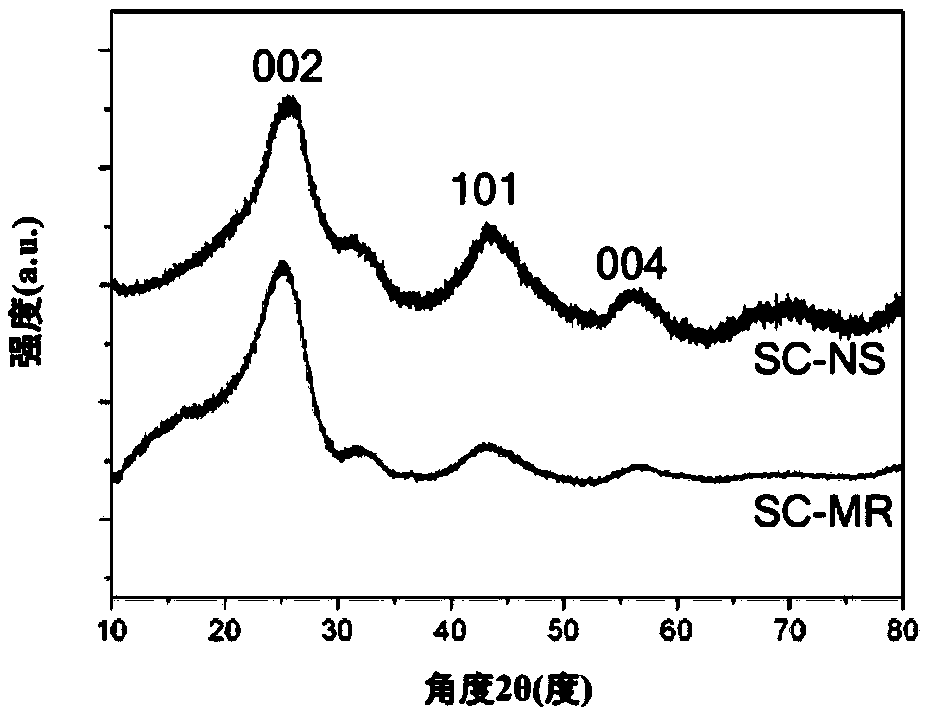

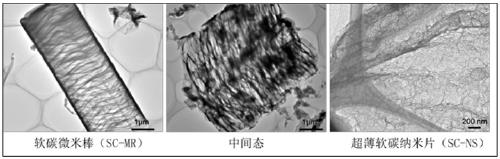

[0035] A preparation method for microporous ultrathin soft carbon nanosheets, which comprises the steps of:

[0036] 1) First, take a certain amount of 3,4,9,10-tetracarboxylic anhydride (PTCDA) in a flowing argon atmosphere at 5°C min -1 Heat up to 900°C for sintering for 10 hours;

[0037] 2) Take 1 g of the soft carbon sample obtained in step 1) and disperse it in 100 ml of water, add 5 g of polyvinylpyrrolidone (PVP), and ultrasonically treat the mixed solution for 12 hours to uniformly disperse;

[0038] 3) Dissolve 5 g of KOH into the solution obtained in step 2), and further stir for 2 h under the condition of a water bath at 60° C. After the stirring is completed, microwave the solution for 5 min under a microwave power of 300 W;

[0039] 4) Wash the obtained solid powder with 1M HCl to remove the remaining KOH, continue washing with water and then dry it in an oven at 70°C in an air atmosphere;

[0040] 5) Under flowing argon atmosphere, at 5°C min -1 The temperatu...

Embodiment 2

[0051] 1) First, take a certain amount of 3,4,9,10-tetracarboxylic anhydride (PTCDA) in a flowing argon atmosphere at 5°C min -1 Heat up to 800°C for sintering for 10h;

[0052] 2) Take 0.5 g of the soft carbon sample obtained in step 1) and disperse it in 100 ml of water, add 5 g of polyvinylpyrrolidone (PVP), and ultrasonically treat the mixed solution for 12 hours to uniformly disperse;

[0053] 3) Dissolve 5 g of KOH into the solution obtained in step 2), and further stir for 2 h under the condition of a water bath at 60° C. After the stirring is completed, microwave the solution for 5 min under a microwave power of 300 W;

[0054] 4) Wash the obtained solid powder with 1M HCl to remove the remaining KOH, continue washing with water and then dry it in an oven at 70°C in an air atmosphere;

[0055] 5) Under flowing argon atmosphere, at 5°C min -1 The temperature was raised from room temperature to 800° C. and kept for 2 hours to finally obtain a microporous ultrathin soft...

Embodiment 3

[0058] 1) First, take a certain amount of 3,4,9,10-tetracarboxylic anhydride (PTCDA) in a flowing argon atmosphere at 5°C min -1 Heat up to 900°C for sintering for 10 hours;

[0059] 2) Take 2 g of the soft carbon sample obtained in step 1) and disperse it in 150 ml of water, add 15 g of polyvinylpyrrolidone (PVP), and ultrasonically treat the mixed solution for 12 hours to uniformly disperse;

[0060] 3) Dissolve 5 g of KOH into the solution obtained in step 2), and further stir for 2 h under the condition of a water bath at 60° C. After the stirring is completed, microwave the solution for 5 min under a microwave power of 100 W;

[0061] 4) Wash the obtained solid powder with 1M HCl to remove the remaining KOH, and dry it in an oven at 70° C. in an air atmosphere;

[0062] 5) Under flowing argon atmosphere, at 5°C min -1 Raise the temperature from room temperature to 800°C and keep it warm for 1.5 hours to finally obtain the microporous ultrathin soft carbon nanosheet elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com