Composite sodium ion positive electrode material with core-shell structure and preparation method thereof

A positive electrode material, sodium ion battery technology, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of large sodium layer spacing, limited industrial application and promotion, and low specific capacity, so as to reduce production and storage costs , large commercial application prospects, and the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) The layered structure material Na synthesized by 4mmol hydrothermal method 0.5 mn 0.5 Ni 0.5 o 2 , added to 40mL of absolute ethanol, and then added 0.4mmol sodium acetate, 0.66mmol manganese acetate and 0.34mmol tetrabutyl titanate, stirred for 20min and then ultrasonically dispersed for 5min to form a dispersion system; then the dispersion system was placed at 60°C environment until the ethanol is completely evaporated to obtain a uniformly mixed powder material;

[0018] (2) Put the above-mentioned powder material in an alumina boat, and heat-treat it in a muffle furnace. The process parameters are 1°C / min to 450°C, heat preservation for 5 hours, and then 3°C / min to 900°C, and heat preservation for 15 hours. hours, and then cooled to room temperature.

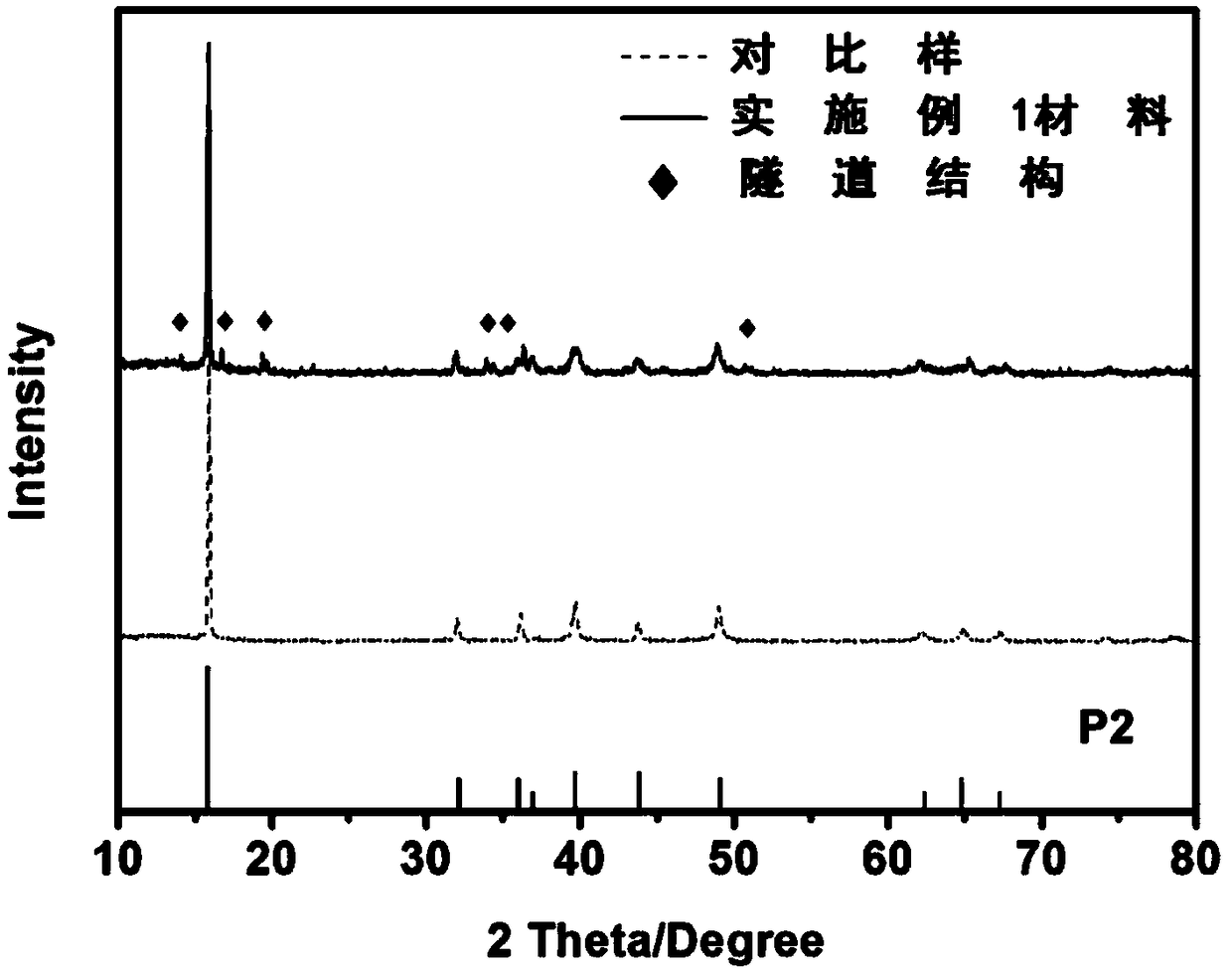

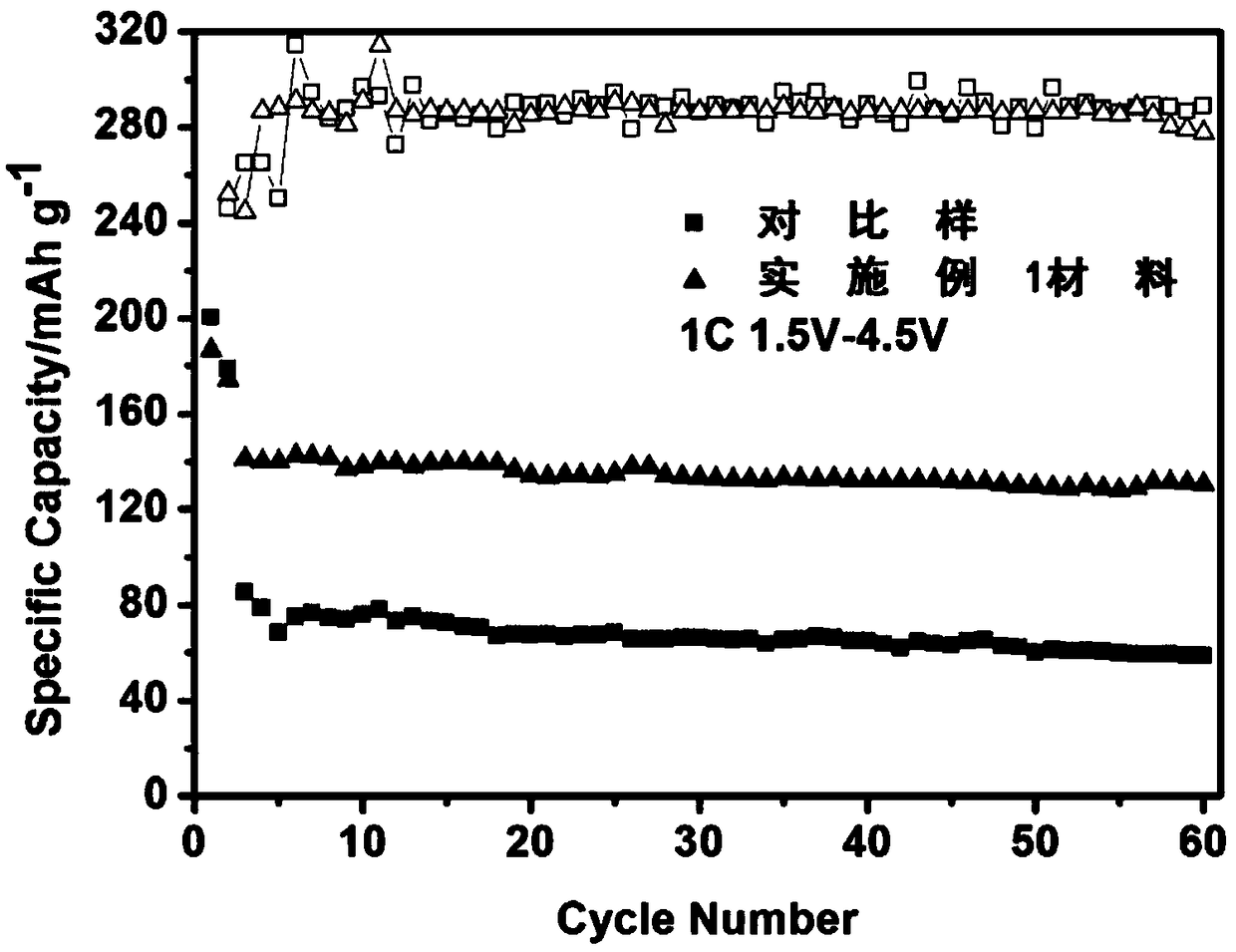

[0019] Adopt above-mentioned method to make a kind of composite sodium ion battery cathode material, have shell-core structure, internal chemical composition is Na 0.5 mn 0.5 Ni 0.5 o 2 , layered structure...

Embodiment 2

[0022] (1) The layered structure material Na synthesized by 5.67mmol coprecipitation method 0.5 mn 0.8 co 0.2 o 2 Add to 40mL deionized water, then add 0.5mmol sodium nitrate, 0.5mmol manganese nitrate, 0.5mmol tetrabutyl titanate to it, stir for 30min, evaporate the solvent water in a water bath at 80°C to obtain a uniformly mixed powder;

[0023] (2) Put the above powder in an alumina boat and heat treat in a muffle furnace. The process parameters are 1°C / min to 500°C, heat preservation for 5 hours, 2°C / min temperature rise to 950°C, heat preservation for 10 hours, and then Naturally cool to room temperature.

[0024] Adopt above-mentioned method to make a kind of composite sodium ion battery cathode material, have core-shell structure, internal chemical composition is Na 0.5 mn 0.8 co 0.2 o 2 , layered structure, accounting for 85% of the total molar ratio; the surface chemical composition is Na 0.5 mn 0.5 Ti 0.5 o 2 , by XRD analysis, the characteristic peaks of...

Embodiment 3

[0026] (1) Grind 0.6mmol sodium nitrate, 0.7mmol manganese acetate, and 0.3mmol titanium dioxide in a mortar evenly, then add 7mmol layered structure material NaMn synthesized by solution combustion method 0.5 V 0.2 Ti 0.3 O continue to grind until evenly mixed;

[0027] (2) Put the above-mentioned uniformly mixed powder in an alumina boat and heat-treat in a muffle furnace. The process parameters are 1°C / min to 400°C, heat preservation for 6 hours, 5°C / min to 900°C, heat preservation 12 hours, then naturally cooled to room temperature.

[0028] A composite sodium-ion battery positive electrode material is prepared by the above method, which has a shell-core structure and an internal chemical composition of NaMn 0.5 V 0.2 Ti 0.3 o 2 , layered structure, accounting for 87.5% of the total molar ratio; the surface chemical composition is Na 0.6 mn0.7 Ti 0.3 o 2 According to XRD analysis, the characteristic peaks of tunnel-like structure appear on the spectrum at 14°, 16....

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com