Low-temperature preparation method of silicon-rich silicon nitride film

A technology of silicon-rich silicon nitride and silicon nitride, which is applied in the field of low-temperature preparation of silicon-rich silicon nitride films, can solve the problems of depositing low-stress, corrosion-resistant silicon-rich silicon nitride films, etc., and achieve the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

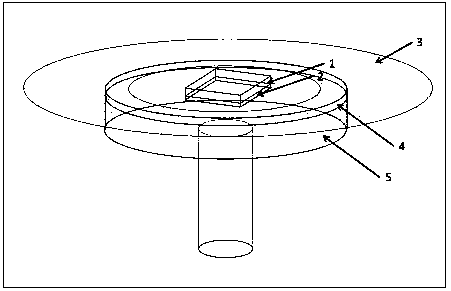

[0019] The accompanying drawings are for illustrative purposes only and cannot be construed as limiting the patent;

[0020] In order to better illustrate this embodiment, some parts in the drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product;

[0021] For those skilled in the art, it is understandable that some well-known structures and descriptions thereof may be omitted in the drawings.

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] like figure 1 As shown, the devices used in the low-temperature preparation method of silicon-rich silicon nitride thin films in the present invention include: 1 is a substrate; 2 is vacuum grease, which is applied under the substrate 1 to transfer heat between the substrate 1 and the carrier; 3 is the lower electrode, which has a coolant pipeline, which is used to control the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com