A lead-supercritical carbon dioxide intermediate heat exchanger

An intermediate heat exchanger, carbon dioxide technology, applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger fixation, etc., can solve the problems of immature design method, large space size, low design efficiency, etc. Effect of heat exchange efficiency and compactness, high heat exchange power, optimized number and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

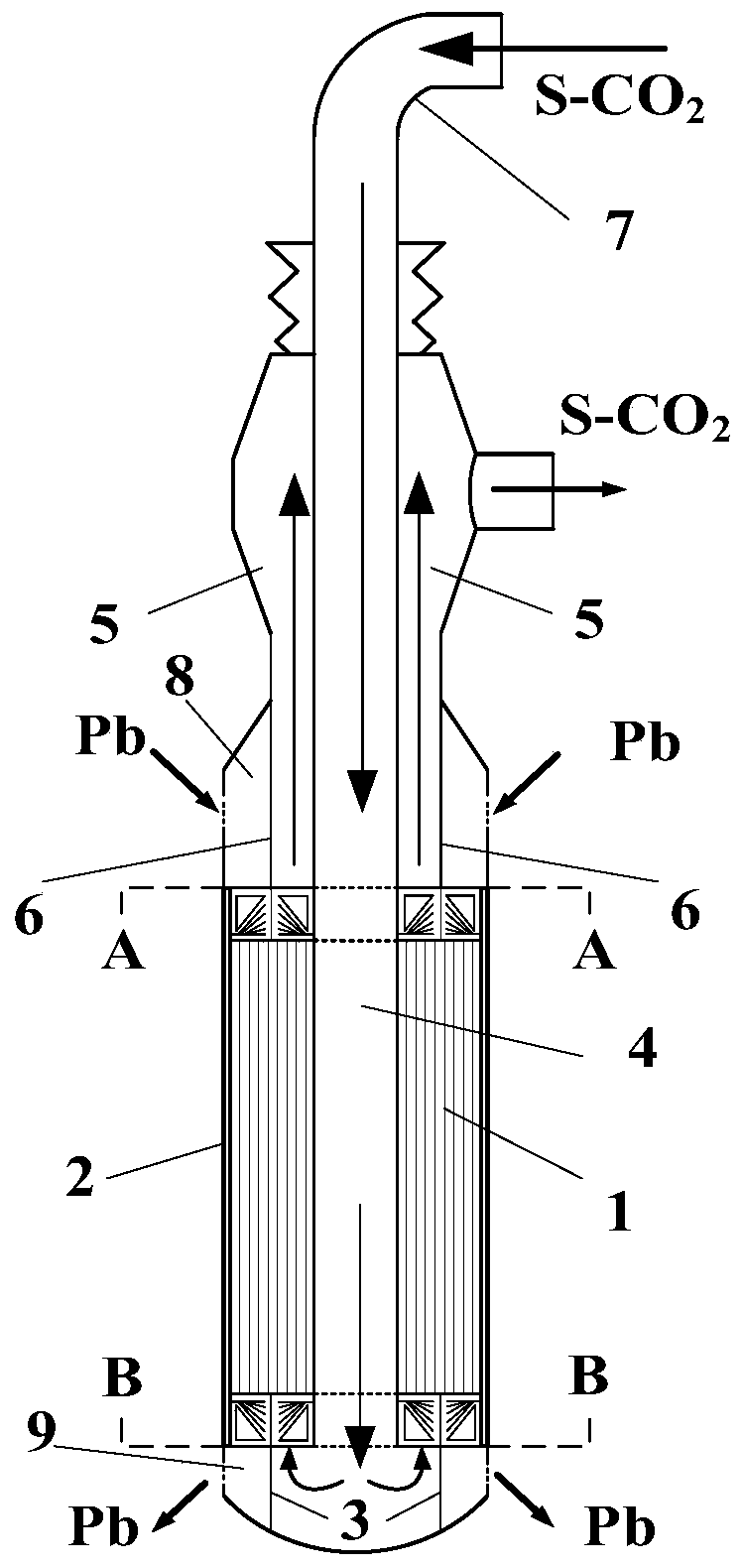

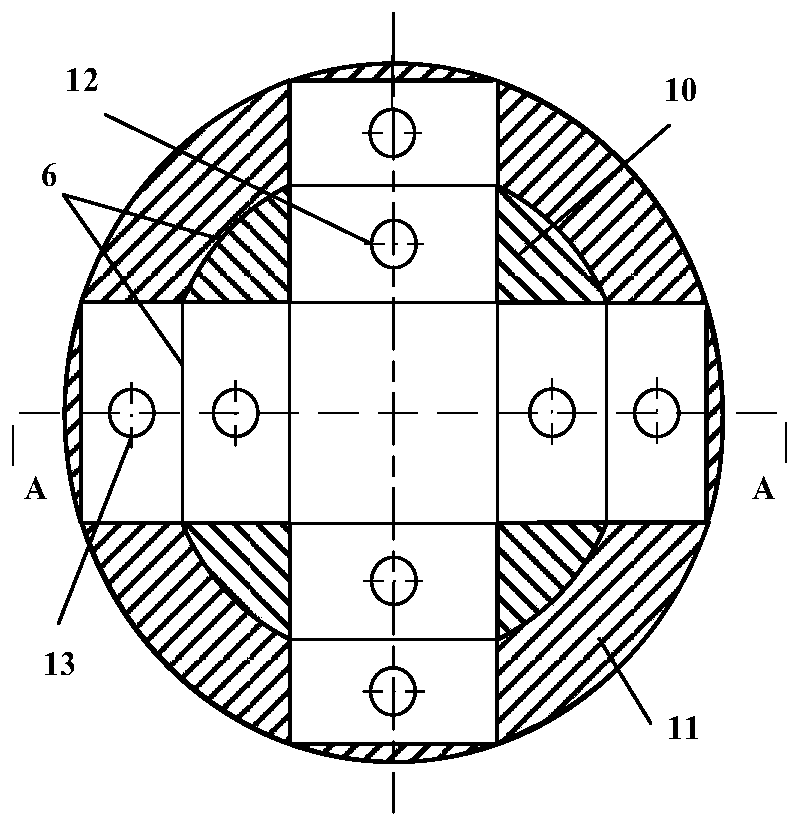

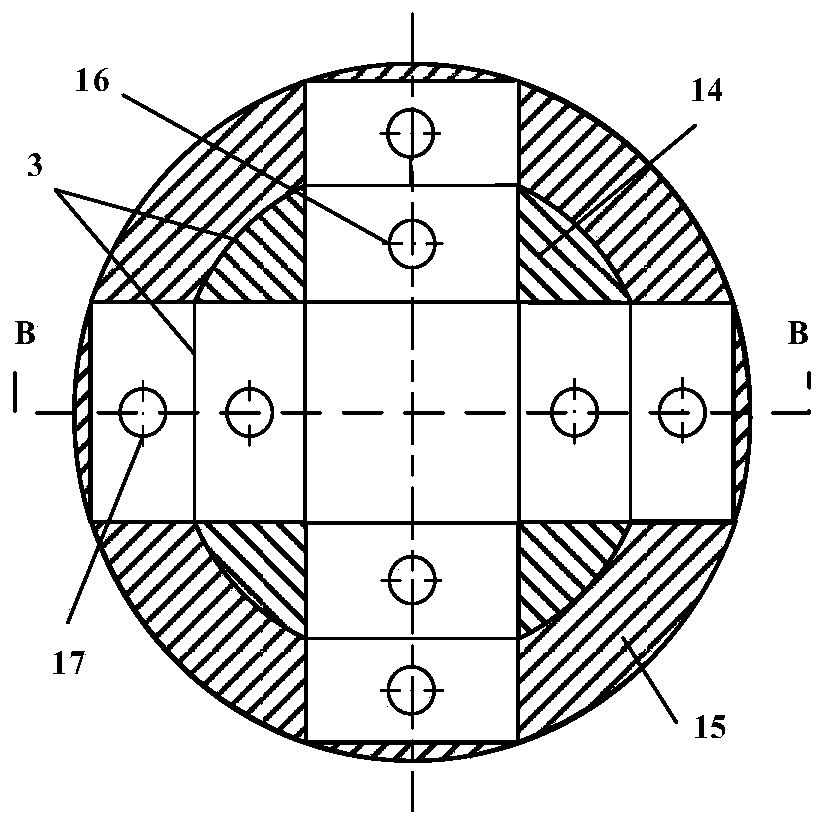

[0027] see Figure 1 to Figure 5 , the present invention includes a cylindrical cylinder 2 with a closed conical structure at the bottom and four modular printed circuit board heat exchangers PCHE1 uniformly arranged around the central axis of the cylindrical cylinder 2, each modular printed circuit board heat exchanger PCHE1 They are all made of a plurality of cold / hot plates made of SS316 stainless steel with semicircular microchannels etched and alternately stacked and diffused. Four modular printed circuit board heat exchangers PCHE1 form the S-CO in the center. 2 Center drop tube 4, S-CO 2 The top of the center downcomer 4 and the S-CO set in the cylindrical shell 2 2The inlet pipes 7 are connected, and the cylindrical cylinder 2 is provided with a liquid lead inlet channel 8 and a liquid lead outlet channel 9, and the cylindrical cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com