Industrial boiler energy-saving and emission-reducing device

An energy-saving and emission-reduction, industrial technology, applied in the direction of boiler working condition indication, combustion method, water/sludge/sewage treatment, etc. Standards and other issues, to achieve the effect of achieving scale-free operation, reducing the generation of nitrogen oxides, and ensuring water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

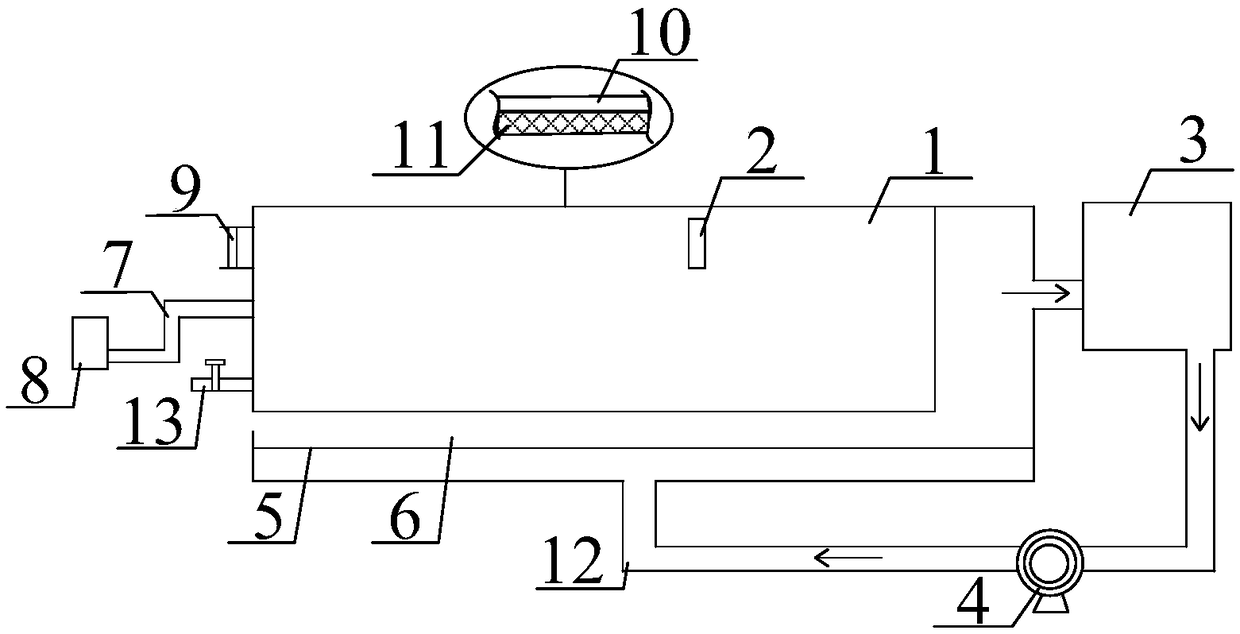

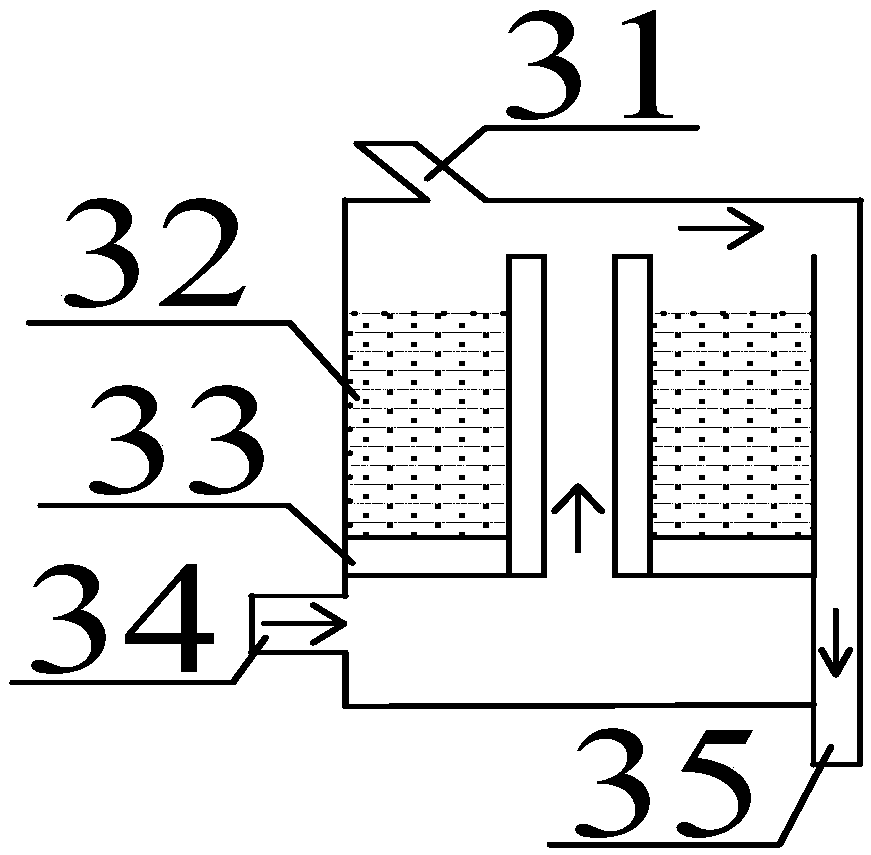

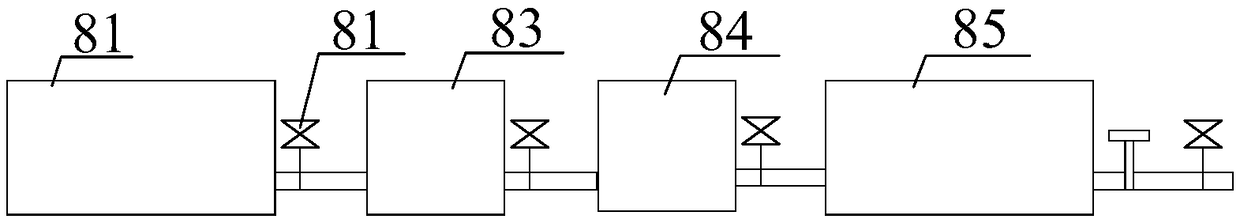

[0020] as attached figure 1 To attach image 3 shown

[0021] The present invention provides an energy-saving and emission-reducing device for industrial boilers, including 1. An energy-saving and emission-reducing device for industrial boilers, characterized in that it includes a boiler 1, a hardness tester 2, a low-nitrogen generator 3, an induced draft fan 4, and a fire grate 5. The furnace 6, the water pipe 7, the water treatment device 8, the water level gauge 9, the insulation layer 10, the furnace wall 11, the smoke pipe 12 and the sewage outlet 13, and the furnace wall 11 is arranged on the outside of the boiler 1; the insulation layer 10 Bonded on the outside of the furnace wall 11; the hardness gauge 2 is fixed on the front side of the boiler 1 by bolts; the water level gauge 9 is fixed on the upper left side of the boiler 1 by bolts; the sewage outlet 13 is opened on the boiler 1 The water treatment device 8 is fixed on the left side of the boiler 1 by bolts, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com