Recompression circulation compact type supercritical carbon dioxide cycle energy supply system for small sodium reactor

A carbon dioxide and recompression technology, which is applied in steam engine installations, steam applications, machines/engines, etc., can solve the problems of energy island volume, heavy auxiliary equipment, and unsuitable miniaturization scenarios, etc., to achieve strong heat carrying capacity and volume zoom out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

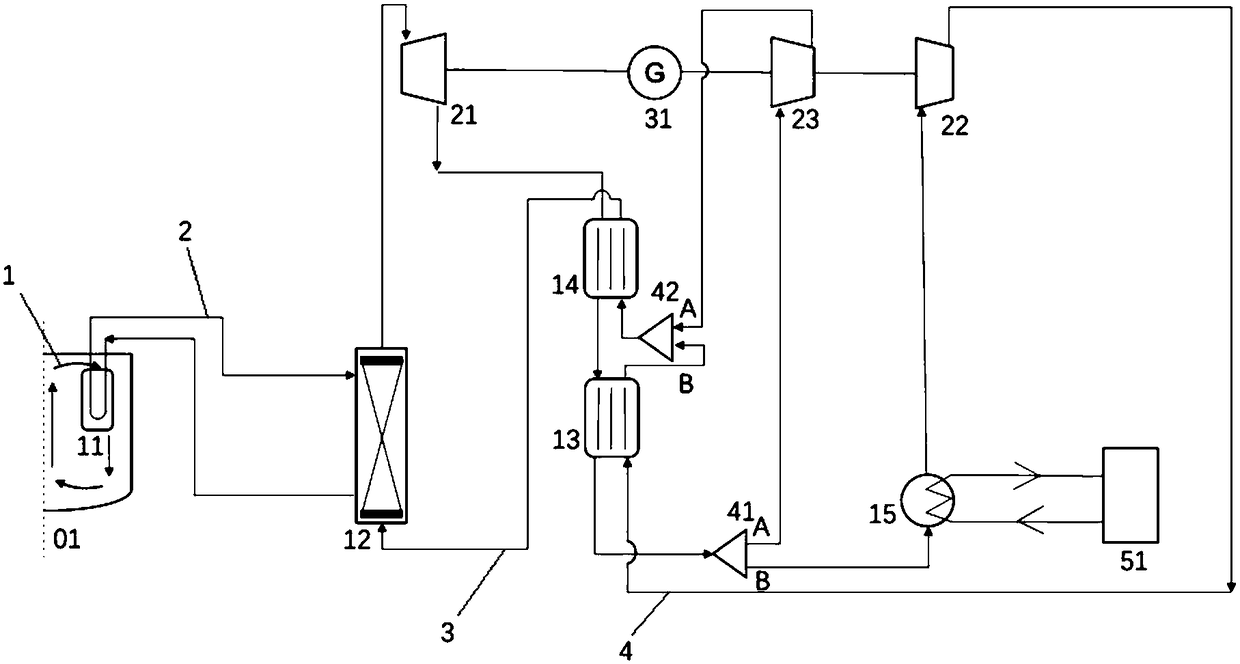

[0017] Specific implementation mode one: combine figure 1 Illustrate this embodiment, the recompression cycle compact supercritical carbon dioxide cycle energy supply system of the small sodium stack of this embodiment includes a first loop 1 for providing a heat source, a second loop 2 for transferring heat, and a second loop 2 for transferring heat. The third loop 3 for converting thermal energy into electrical energy and the fourth loop 4 for heating pipe network, the circulating fluid of the first loop 1 and the second loop 2 is sodium, the circulating fluid of the third loop 3 and the fourth loop For carbon dioxide, the heat exchange between the first circuit 1 and the second circuit 2 is carried out through the sodium-sodium heat exchanger 11, and the heat exchange between the second circuit 2 and the third circuit 3 is carried out through the sodium-carbon dioxide heat exchanger 12 and realized Power supply, the third circuit 3 is connected with a low-temperature regene...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 Describe this embodiment, the recompression cycle compact supercritical carbon dioxide cycle energy supply system of the small-scale sodium stack of this embodiment, the third circuit 3 is also provided with a high-temperature regenerator 14, the outlet of the turbine 21 and the high-temperature regenerator The hot end inlet of 14 is connected, the hot end outlet of the high temperature regenerator 14 is connected with the hot end inlet of the low temperature regenerator 13, the hot end outlet of the low temperature regenerator 13 is connected with the inlet end of the fourth circuit 4, and the fourth circuit The outlet end of 4 is connected with the cold end inlet of the low temperature regenerator 13, the cold end outlet of the low temperature regenerator 13 is connected with the cold end inlet of the high temperature regenerator 14, and the cold end outlet of the high temperature regenerator 14 is connected with t...

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 Describe this embodiment, the recompression circulation compact type supercritical carbon dioxide circulation energy supply system of the small-sized sodium stack of this embodiment, described fourth circuit 4 is provided with recompressor 23 in parallel, recompressor 23 and turbine 21 , the generator 31 and the main compressor 22 are coaxially arranged, and the fourth circuit 4 is also provided with a flow divider 41 and a flow confluence 42. The outlet of the hot end of the low-temperature regenerator 13 is connected to the inlet of the flow divider 41, and through the flow divider 41 One end of the two streams is connected to the cooler 15, the outlet of the cooler 15 is connected to the inlet of the main compressor 22, the outlet of the main compressor 22 is connected to the inlet of the cold end of the low-temperature regenerator 13, and the outlet of the two streams through the splitter 41 The other end is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com