Preparation and application of a kind of non-cleaning decontamination product for fluffy fabrics

A fabric and fluffy technology, which is applied in the preparation of detergent mixture compositions, detergent materials, detergent compounding agents, etc., can solve problems such as affecting user experience, endangering health, and losing fluffy feeling, and achieves good decontamination and decontamination. Odor effect, rapid penetration, and permeability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

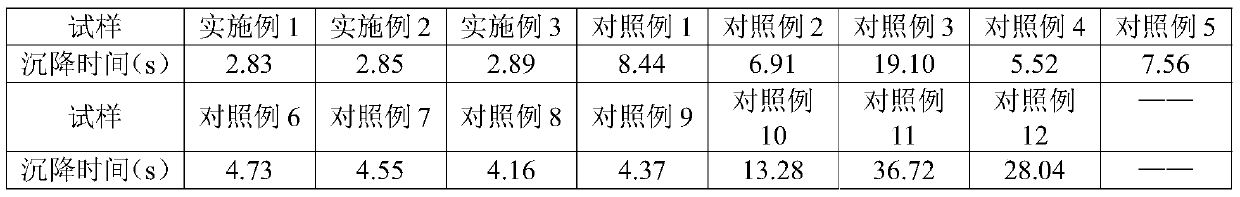

Examples

Embodiment 1

[0031] Add 17.5 parts of isooctyl alcohol polyoxyethylene ether JFC-3, 12.5 parts of isomeric tridecyl alcohol polyoxyethylene ether TO-6, 12 parts of isomeric decanol polyoxyethylene ether E-1005, and 8 parts of tea Saponin, 8.5 parts of polyether-amino modified silicone oil, 11.5 parts of cetyl dimethyl ethyl ammonium bromide, 12 parts of fluffy and smooth silicone oil, then add 85 parts of hydrophilic caprylic acid glyceride, 540 120 parts of deionized water, 120 parts of d-limonene, 150 parts of ethanol, stir while adding, and then add 8 parts of neutral lipase, 4 parts of serrapeptase, 3 parts of cellulose compound enzyme, 8 parts of ten Tetraalkyl dimethyl benzyl ammonium chloride, and finally homogenize at 800 rpm for 2.5 min, and seal the package.

Embodiment 2

[0033]Add 17 parts of isooctyl alcohol polyoxyethylene ether JFC-3, 13 parts of iso-tridecanol polyoxyethylene ether TO-6, 11.5 parts of isomeric decanol polyoxyethylene ether E-1005, and 8.5 parts of tea Saponin, 8.5 parts of polyether-amino modified silicone oil, 12 parts of cetyl dimethyl ethyl ammonium bromide, 12 parts of fluffy and smooth silicone oil, then add 85 parts of hydrophilic caprylic acid glyceride, 538 122 parts of deionized water, 122 parts of d-limonene, 150 parts of ethanol, stir while adding, and then add 7.5 parts of neutral lipase, 4 parts of serrapeptase, 3.5 parts of cellulose compound enzyme, 7.5 parts of ten Tetraalkyl dimethyl benzyl ammonium chloride, and finally homogenize at 800 rpm for 2.5 min, and seal the package.

Embodiment 3

[0035] Add 17.5 parts of isooctyl alcohol polyoxyethylene ether JFC-3, 13 parts of isomeric tridecyl alcohol polyoxyethylene ether TO-6, 11 parts of isomeric decanol polyoxyethylene ether E-1005, and 8.5 parts of tea Saponin, 9 parts of polyether-amino modified silicone oil, 12 parts of cetyldimethylethylammonium bromide, 11 parts of fluffy and smooth silicone oil, then add 82 parts of hydrophilic caprylic acid glyceride, 533 125 parts of deionized water, 125 parts of d-limonene, 155 parts of ethanol, stir while adding, and then add 7.5 parts of neutral lipase, 4 parts of serrapeptase, 3.5 parts of cellulose compound enzyme, 8 parts of ten Tetraalkyl dimethyl benzyl ammonium chloride, and finally homogenize at a speed of 1000 rpm for 2 min, and seal the package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com