Toilet detergent and preparation method thereof

A toilet cleaning agent, polyoxyethylene ether technology, applied in chemical instruments and methods, detergent compounding agent, detergent composition and other directions, can solve the problems of poor disinfection effect, incomplete bacteriostatic effect of toilet cleaning agent, etc. Low cost, good decontamination and deodorization effect, strong antibacterial and disinfection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

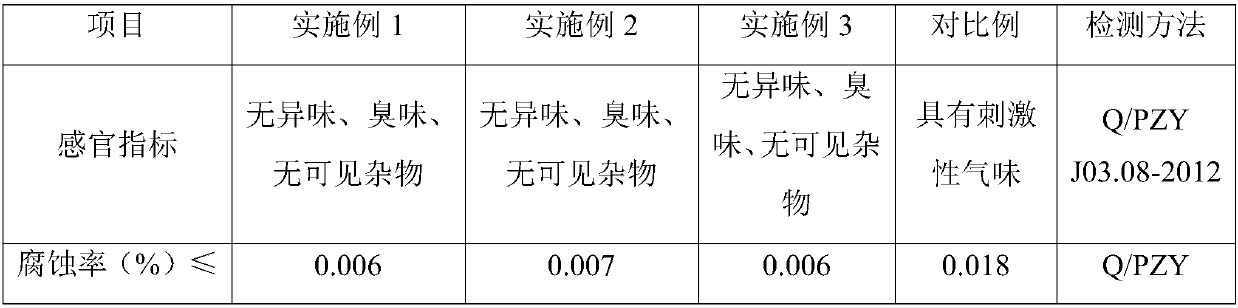

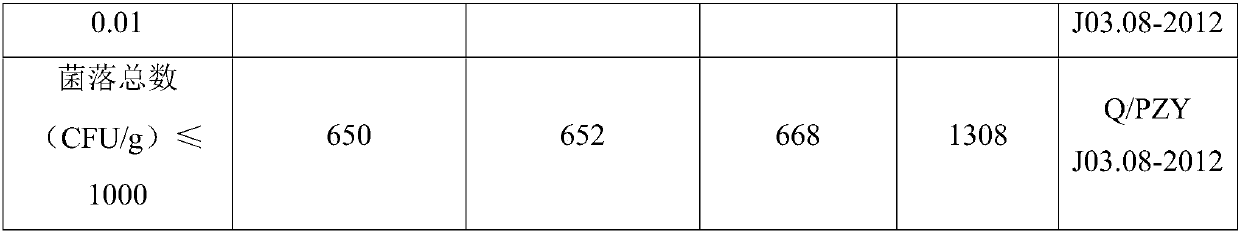

Examples

preparation example Construction

[0021] The embodiment of the present invention also provides a preparation method of a toilet cleaning agent, and the method is realized by the following steps:

[0022] Step 1, respectively weigh the following components by mass percentage: fatty acid triethanolamine 6.0-7.0%, isomeric alcohol polyoxyethylene ether 3.0-4.5%, alkyl glycoside 5.0-7.0%, sodium citrate 4.0-4.5%, chlorine Sodium 0.2-1.8%, boric acid 0.8-1.5%, sodium bicarbonate 2.2-2.4%, sodium carbonate 1.5-2.0%, hydrogen peroxide 0.5-1.5%, fragrance 0.1-2.0%, ethanol 1.0-1.5%, the rest are Deionized water; wherein, the isomeric alcohol polyoxyethylene ether is one or more of isomeric ten alcohol polyoxyethylene ether, isomeric undecyl alcohol polyoxyethylene ether, and isomeric tridecanol polyoxyethylene ether; The spice is one or more of rose extract, papaya extract or lavender extract; the mass percentage concentration of hydrogen peroxide is 27-35%;

[0023] Step 2, adding sodium chloride, sodium bicarbonate...

Embodiment 1

[0029] Step 1, respectively weigh the following components by mass percentage: fatty acid triethanolamine 5.0%, isomerized tenol polyoxyethylene ether 4.0%, alkyl glycoside 6%, sodium citrate 4.3%, sodium chloride 0.8%, boric acid 1.1% %, sodium bicarbonate 2.3%, sodium carbonate 1.7%, hydrogen peroxide 0.9%, lavender extract 1.5%, ethanol 1.2%, and the rest are deionized water;

[0030] Step 2, adding sodium chloride, sodium bicarbonate, sodium carbonate, boric acid and sodium citrate described in step 1 into deionized water, stirring evenly, and heating to 65°C to obtain a first intermediate mixture;

[0031] Step 3, mixing and stirring fatty acid triethanolamine, iso-alcohol polyoxyethylene ether and alkyl glycoside evenly and heating to 40°C to obtain a second intermediate mixture;

[0032] Step 4, adding the second intermediate mixture obtained in step 3 to the first intermediate mixture obtained in step 2, stirring evenly, and letting it stand to room temperature to obta...

Embodiment 2

[0035] Step 1, respectively weigh the following components by mass percentage: fatty acid triethanolamine 6.0%, isomerized decahydrin 4.5%, alkyl glycoside 5.0%, sodium citrate 4.5%, sodium chloride 1.8%, boric acid 1.5% %, sodium bicarbonate 2.2%, sodium carbonate 2.0%, hydrogen peroxide 1.5%, fragrance 0.1%, ethanol 1.5%, and the rest are deionized water;

[0036] Step 2, adding sodium chloride, sodium bicarbonate, sodium carbonate, boric acid and sodium citrate described in step 1 into deionized water, stirring evenly, and heating to 60° C. to obtain a first intermediate mixture;

[0037] Step 3, mixing and stirring fatty acid triethanolamine, iso-alcohol polyoxyethylene ether and alkyl glycoside evenly and heating to 30°C to obtain a second intermediate mixture;

[0038] Step 4, adding the second intermediate mixture obtained in step 3 to the first intermediate mixture obtained in step 2, stirring evenly, and letting it stand to room temperature to obtain a third intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com