HTPB (hydroxy-terminated polybutadiene) based casting mixed explosive formula with improved process property

A technology of mixed explosives and process performance, which is applied in the direction of explosives, non-explosive/non-thermal agent components, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., and can solve the requirements that cannot effectively reduce the viscosity and vacuum degree of the slurry Higher, process performance and other issues, to achieve the effect of improving fluidity and leveling, improving fluidity, and promoting surface coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

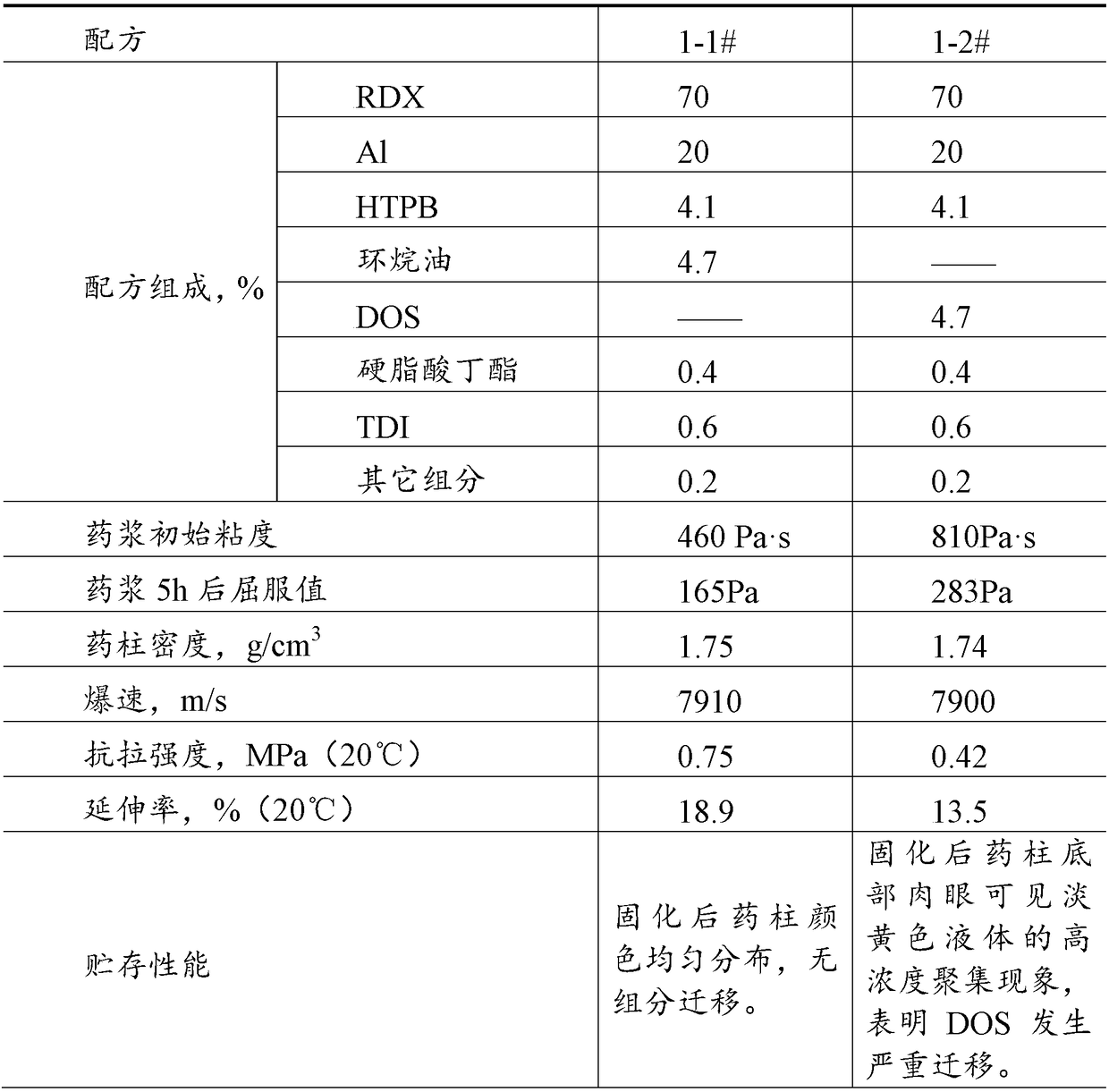

[0029] Using DOS and naphthenic oil as plasticizers, two formulations of HTPB-based castable mixed explosives with RDX as the main explosive component were prepared. The formulation composition and properties are shown in Table 1 below.

[0030] Table 1 The formula composition and properties of DOS and naphthenic oil as plasticizer and RDX as main explosive respectively

[0031]

[0032] Note: Other components in cast explosives include anti-aging agent, curing catalyst, bonding agent, etc., and the following formulas are the same.

[0033] The slurry viscosity test instrument is a HAAKE rotational rheometer, the test temperature is 50°C when the curing agent is TDI, and the test temperature is 60°C when the curing agent is IPDI. The following formula test methods are the same.

[0034] Formula 1 is a 90% solid content aluminum-containing RDX-based pouring explosive, and the plasticizing ratio of the formula is 1.15. Compared with plasticizer DOS, the cast explosive formul...

Embodiment 2

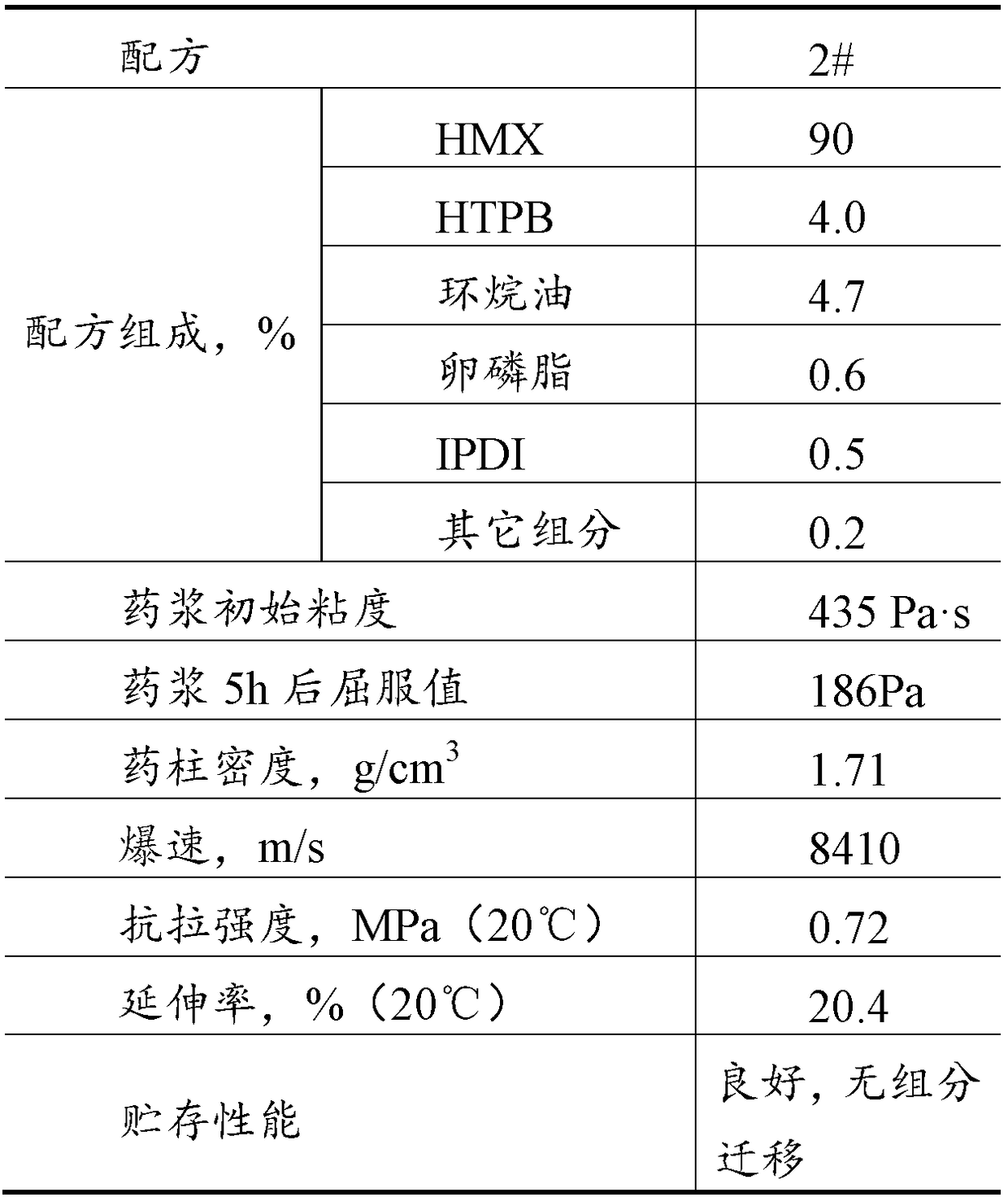

[0036] A formulation of HTPB-based pouring explosives with HMX as the main explosive and naphthenic oil and lecithin was prepared. The formulation composition, initial viscosity of the slurry, yield value of the slurry after 5 hours, density of the explosive, and detonation velocity are shown in Table 2. Show.

[0037] Table 2 Formulation and properties of a HTPB-based pouring explosive with HMX as the main explosive

[0038]

[0039] The pouring explosive 2# formulation with 90% HMX solid content has an initial viscosity of 435Pa·s, a low yield value after 5 hours of slurry, excellent formulation process performance, and an explosive density of 1.71g / cm 3, explosive detonation velocity 8410m / s.

Embodiment 3

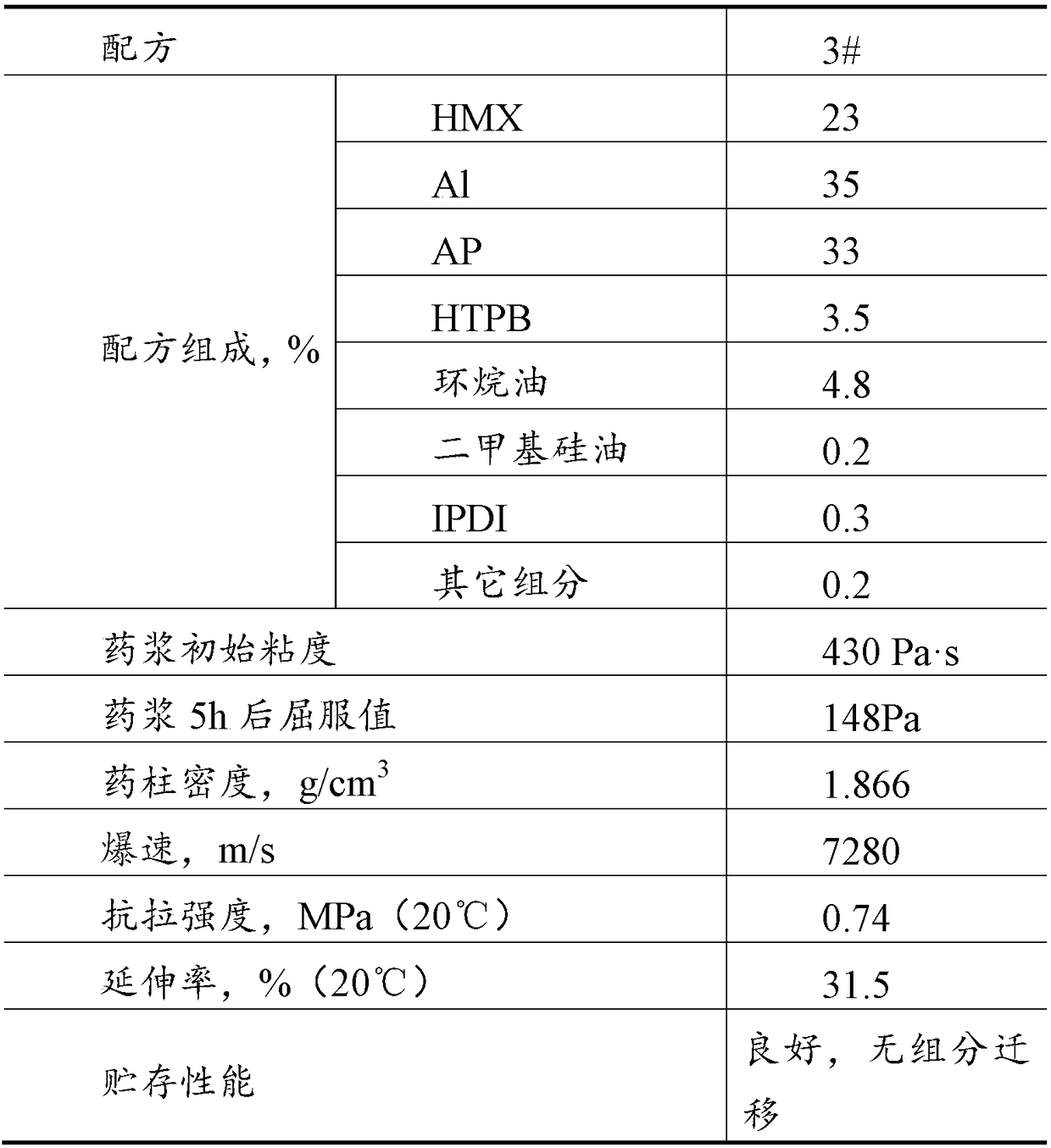

[0041] A HTPB-based pouring explosive formula with HMX as the main explosive and naphthenic oil and simethicone oil was prepared. The formula composition, initial viscosity of the slurry, yield value of the slurry after 5 hours, density of the explosive, detonation velocity and other basic properties as shown in Table 3.

[0042] Table 3 Formula and performance of a HTPB-based pouring explosive with HMX as the main explosive

[0043]

[0044] The solid content of the pouring explosive formula is as high as 91%. The technological performance of the slurry is maintained well, the initial viscosity is low, the pot life is more than 5 hours, the detonation velocity is 7280m / s, and the mechanical properties and storage performance of the explosive are good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Yield value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com