Green-white fluorescent silver quantum cluster-doped fluorphosphate glass based on non-bridging oxygen coordination and preparation method thereof

A technology of heterofluorophosphate and silver quantum, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] By composition 38.4ZnF 2 -40P 2 o 5 -10SnO 2 -10In 2 o 3 -1.6Ag (mol%), weighed ZnF 2 、H 3 PO 4 , SnO 2 、In 2 o 3 and AgNO 3 powder raw material. ZnF 2 、H 3 PO 4 and AgNO 3 The raw material powder is mixed evenly in an agate mortar, placed in a corundum crucible, melted in an air atmosphere at 1150°C for 45 minutes, poured the glass melt into a copper mold to form a glass block, and then used an agate mortar It is crushed and ground into powder. glass powder with SnO 2 、In 2 o 3 Mix the powder raw materials evenly in an agate mortar, place them in a corundum crucible, and melt them in an air atmosphere at 1000°C for 45 minutes. Pour the glass melt into a copper mold to form a glass block. After surface grinding, Polished to make a transparent glass sheet.

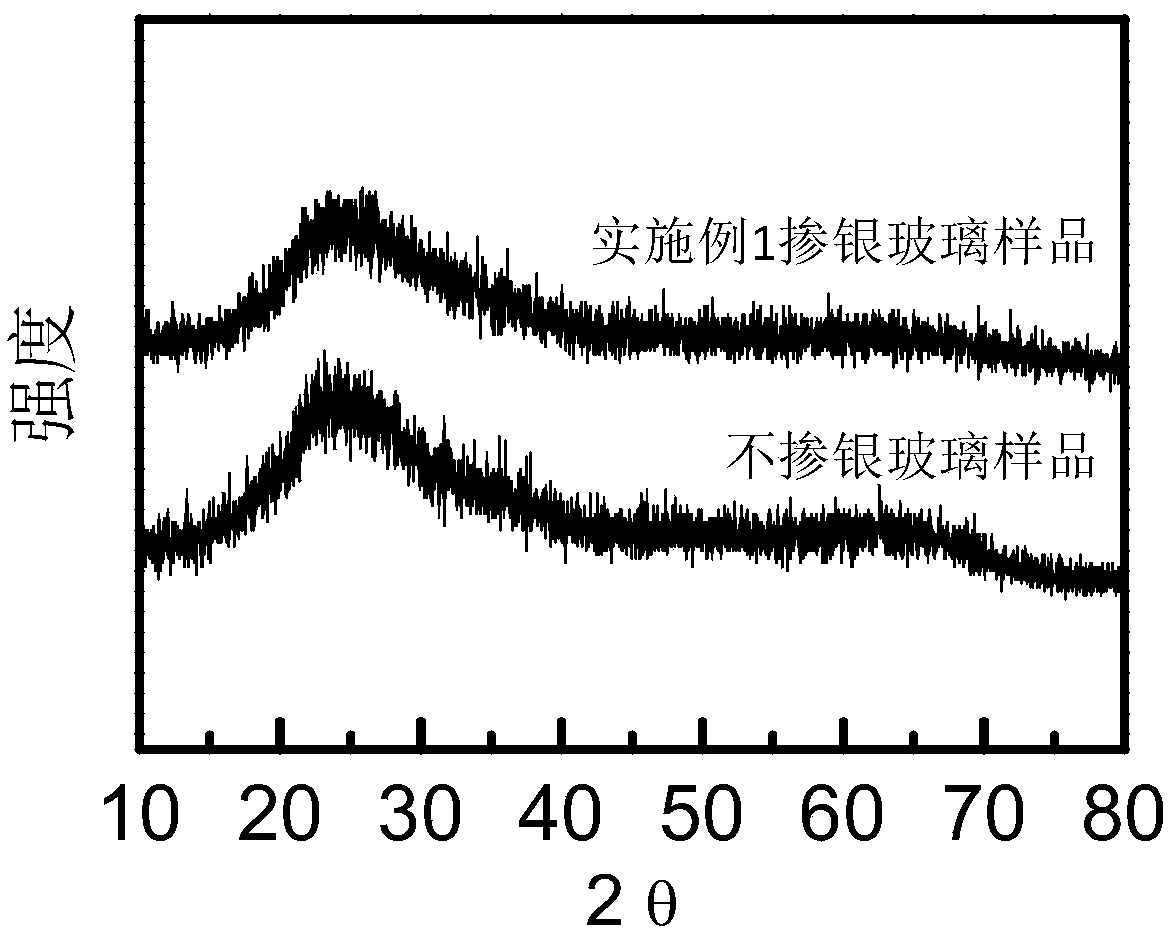

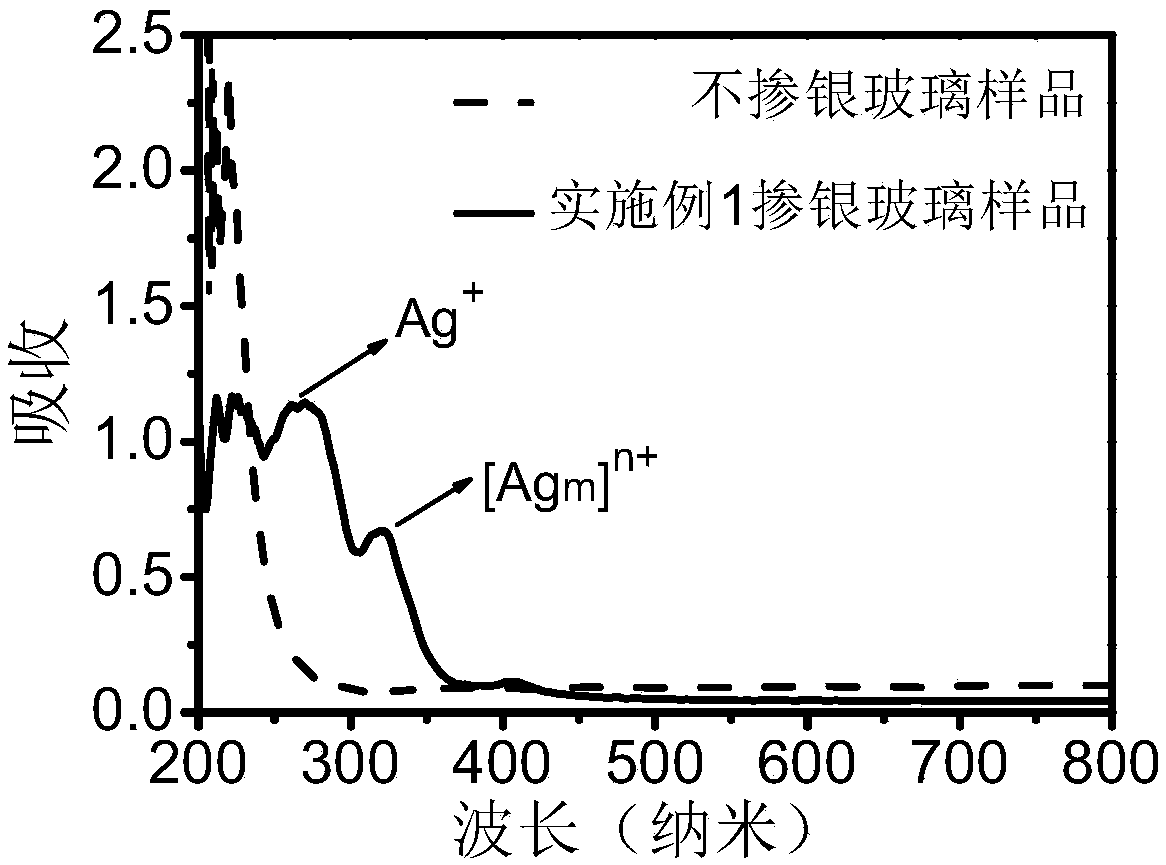

[0021] like figure 1 As shown, XRD analysis shows that the glass sample is an amorphous phase. The silver quantum clusters in the glass can be detected by transmission electron microscope, abso...

Embodiment 2

[0023] By composition 29.9ZnF 2 -55P 2 o 5 -10SnO 2 -5In 2 o 3 -0.1Ag(mol%), weighed ZnF 2 、H 3 PO 4 , SnO 2 、In 2 o 3 and AgNO 3 powder raw material. ZnF 2 、H 3 PO 4 and AgNO 3 The raw material powder is mixed evenly in an agate mortar, placed in a corundum crucible, melted at 1150°C in an air atmosphere for 30 minutes, poured the glass melt into a copper mold to form a glass block, and then used an agate mortar It is crushed and ground into powder. glass powder with SnO 2 、In 2 o 3 Mix the powder raw materials evenly in an agate mortar, place them in a corundum crucible, and melt them in an air atmosphere at 1000°C for 30 minutes. Pour the glass melt into a copper mold to form a glass block. After surface grinding, Polished to make a transparent glass sheet.

[0024] XRD analysis shows that the glass sample is amorphous phase. The transmission electron microscope photo of the glass shows that there are a large number of sub-nanometer silver quantum clus...

Embodiment 3

[0026] By composition 55ZnF 2 -32P 2 o 5 -5SnO 2 -5In 2 o 3 -3Ag (mol%), weighed ZnF 2 、H 3 PO 4 , SnO 2 、In 2 o 3 and AgNO 3 powder raw material. ZnF 2 、H 3 PO 4 and AgNO 3 The raw material powder is mixed evenly in an agate mortar, placed in a corundum crucible, and melted at 1250°C in an air atmosphere for 60 minutes, pouring the glass melt into a copper mold to form a glass block, and then using an agate mortar It is crushed and ground into powder. glass powder with SnO 2 、In 2 o 3 Mix the powder raw materials evenly in an agate mortar, place them in a corundum crucible, and melt them in an air atmosphere at 1100°C for 60 minutes. Pour the glass melt into a copper mold to form a glass block. After surface grinding, Polished to make a transparent glass sheet.

[0027] XRD analysis shows that the glass sample is amorphous phase. The transmission electron microscope photo of the glass shows that there are a large number of sub-nanometer silver quantum cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com