Far infrared heating mouse pad and preparation method thereof

A technology of far-infrared heating and far-infrared heating paper, applied in the far-infrared field, can solve the problems of uneven temperature distribution, unfavorable human health, and rapid heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the present invention, the material of the far-infrared heating paper layer is preferably aramid far-infrared paper, and the aramid far-infrared paper is preferably prepared from carbon nanotubes, aramid chopped fibers and aramid pulp fibers. In the present invention, the preparation method of described aramid fiber far-infrared paper preferably comprises the following steps:

[0038] (1) Mixing aramid chopped fibers, debonder and water, followed by washing and beating, to obtain aramid chopped fibers slurry;

[0039] (2) mixing aramid pulp fiber and aramid pulp fiber dispersant with water to obtain aramid pulp fiber slurry;

[0040] (3) mixing carbon nanotubes, a carbon nanotube dispersant and a solvent to obtain a carbon nanotube dispersion;

[0041] (4) mixing the carbon nanotube dispersion obtained in step (3), the aramid chopped fiber slurry obtained in step (1) and the aramid pulp fiber slurry obtained in step (2) followed by beating and shear treatment to ob...

Embodiment 1

[0060] Weigh 5 g of aramid chopped fiber and 0.1 g of sodium dodecylbenzene sulfonate in an aqueous solution, let it soak for 20 minutes, wash it 4 times, beat it with a beater for 10 minutes, and prepare aramid chopped fiber slurry.

[0061] Weigh 5 g of aramid pulp fiber and 0.1 g of polyethylene oxide in an aqueous solution, and stir for 5 minutes to obtain aramid pulp fiber slurry.

[0062] Weigh 5g of carbon nanotubes and 0.1g of sodium lauryl sulfate in an alcohol solvent, ultrasonicate for 30min, and shear at high speed for 30min to obtain a carbon nanotube dispersion. After the lentil chopped fiber slurry and the aramid pulp fiber slurry are uniformly mixed, beat with a beater for 10 minutes, and cut with a high-speed shear for 60 minutes.

[0063] The mixed slurry prepared above was formed by suction filtration through a paper sheet former, and after the wet paper sheet was uncovered, it was vacuum-dried at 80°C and hot-pressed to obtain an aramid fiber far-infrared p...

Embodiment 2

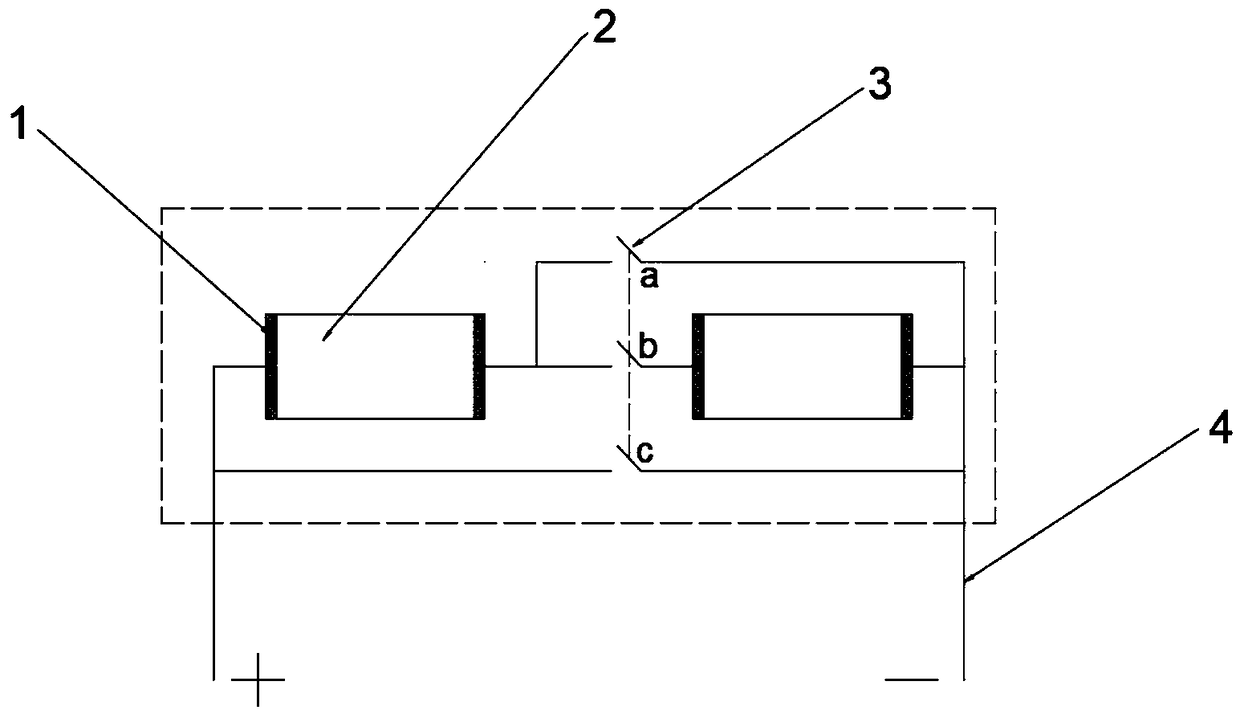

[0065] The aramid fiber far-infrared paper that embodiment 1 makes is cut into the far-infrared heating paper that thickness is 0.2mm, and length is 200mm, and width is 100mm, and copper grid electrode is pressed at far-infrared paper two ends, and then two far-infrared papers are arranged according to figure 1 The circuit structure shown is connected to obtain a far-infrared heating paper layer, wherein 1 is a copper mesh electrode, 2 is a far-infrared heating paper, 3 is a combination switch, and 4 is a wire.

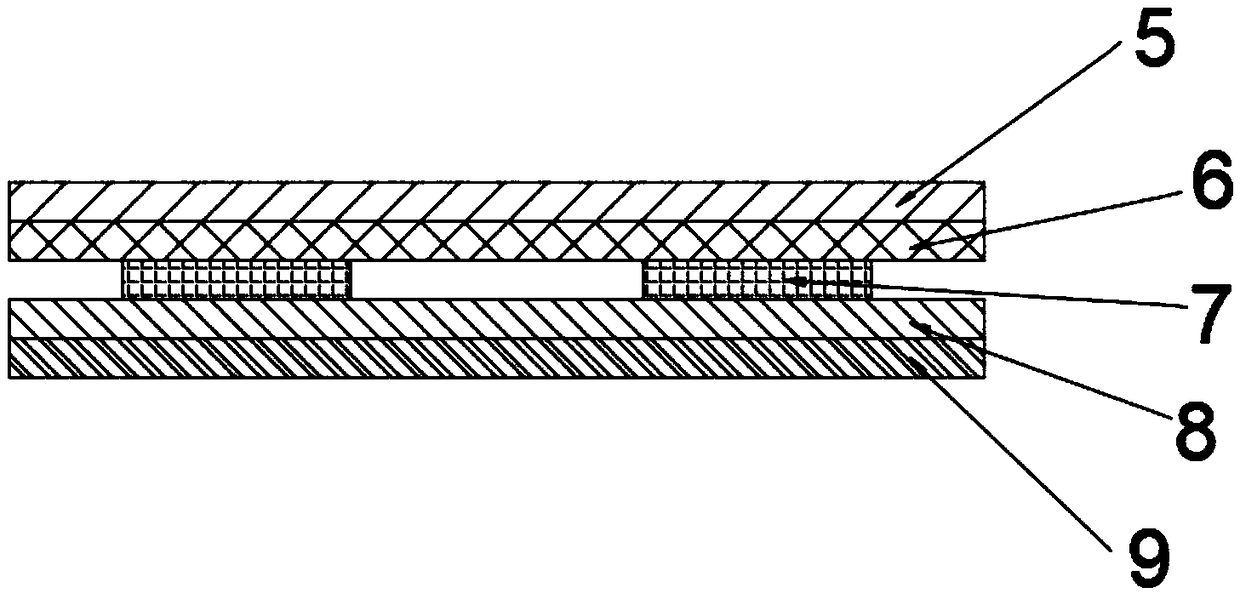

[0066] according to figure 2 In the shown structure, glue is used to press and bond the surface layer 5, insulating and heat-conducting layer 6, far-infrared heating paper layer 7, insulating and heat-reflecting film layer 8, and bottom layer 9 stacked from top to bottom to obtain a far-infrared heating mouse pad.

[0067] Among them, the material of the surface layer is nylon cloth, the material of the insulating and heat-conducting layer is polyimide film with a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com