Fine polishing sponge and preparation method thereof

A technology of fine polishing and grinding layer, which is applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of low yield rate of processed products, fast abrasive consumption, and many scratches on the surface of products, to improve the Grinding and polishing life, improving adhesion, and beneficial to fine polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

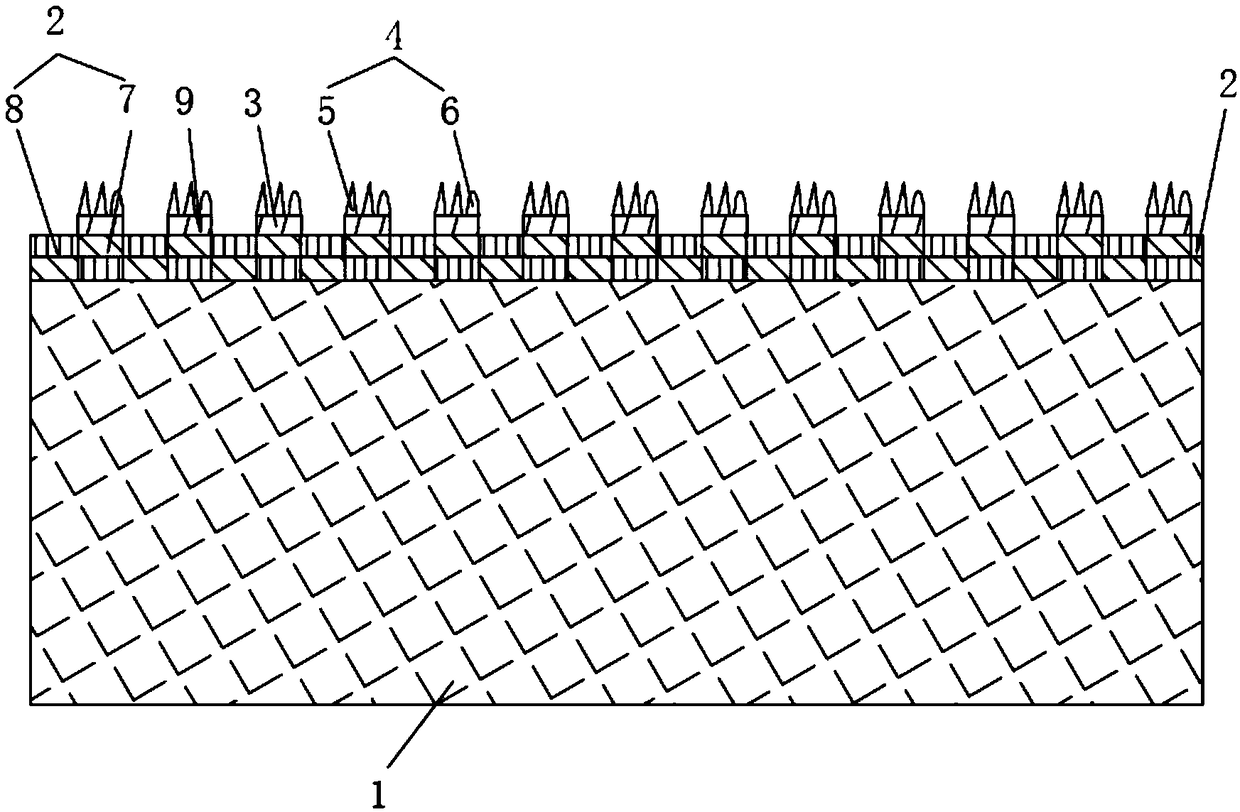

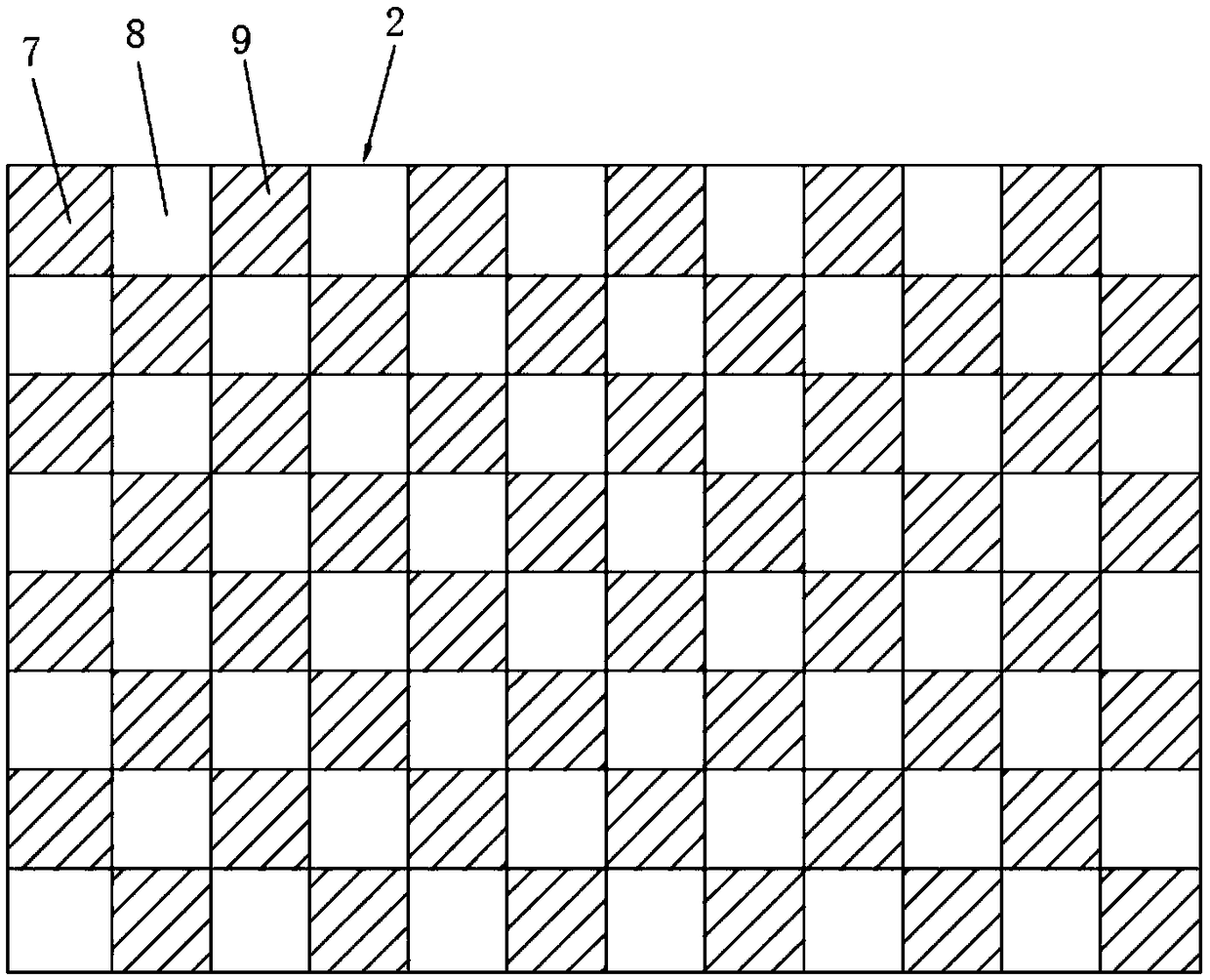

[0054] A kind of fine polishing cotton, such as figure 1 and figure 2 As shown, it includes sequentially compounded sponge layer 1, base cloth layer 2 and abrasive layer 4, and the side of the base cloth layer 2 close to the abrasive layer 4 is provided with a Concentrated adhesive layer 3, the grinding layer 4 includes a resin matrix, a plurality of main grinding units 5 for grinding and polishing adhered to the resin matrix and a plurality of auxiliary grinding units for assisting the main grinding unit 5 in grinding and polishing Unit 6, the main grinding unit 5 is conical, the tip of the main grinding unit 5 protrudes from the upper surface of the resin matrix, and the end of the main grinding unit 5 protruding from the resin matrix is higher than the auxiliary grinding unit 6 Protruding from the end of the resin matrix, the base fabric layer 2 is interwoven with a plurality of warp threads 7 and a plurality of weft threads 8, and the warp threads 7 include a plurality...

Embodiment 2

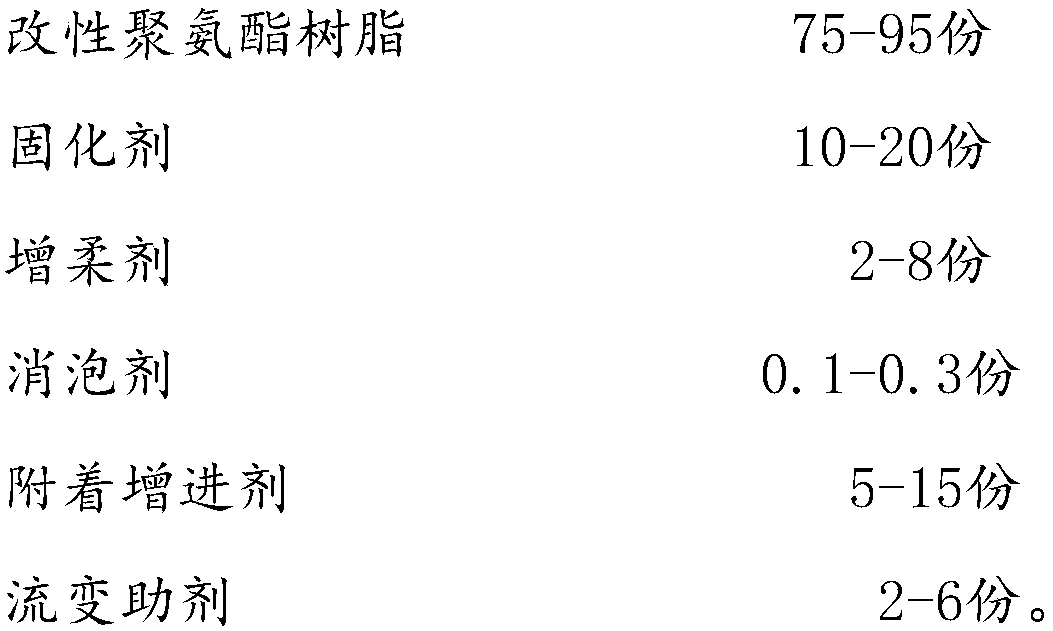

[0057] A preparation method for fine polishing cotton, the structure of the fine polishing cotton is the same as that of Example 1, the bonding layer is formed by solidifying the base cloth treatment liquid, the main grinding unit is abrasive particles, and the auxiliary grinding unit as grinding aid particles;

[0058] The preparation method of described fine polishing cotton comprises the steps:

[0059] (1) base cloth adhesion enhancement treatment, the base cloth treatment liquid is sprayed on the upper surface of the sizing part of the base cloth layer, then dried to solidify the base cloth treatment liquid, and a pretreated base cloth is obtained;

[0060] (2) Preparation of mortar: uniformly mixing abrasive particles, grinding aid particles and resin matrix, and then filtering under pressure to obtain mortar;

[0061] (3) Putting glue sand: spraying the glue sand prepared in the surface coating step (2) on the pretreatment base cloth with the base cloth treatment liqui...

Embodiment 3

[0077] A preparation method for fine polishing cotton, the structure of the fine polishing cotton is the same as that of Example 1, the bonding layer is formed by solidifying the base cloth treatment liquid, the main grinding unit is abrasive particles, and the auxiliary grinding unit as grinding aid particles;

[0078] The preparation method of described fine polishing cotton comprises the steps:

[0079] (1) base cloth adhesion enhancement treatment, the base cloth treatment liquid is sprayed on the upper surface of the sizing part of the base cloth layer, then dried to solidify the base cloth treatment liquid, and a pretreated base cloth is obtained;

[0080] (2) Preparation of mortar: uniformly mixing abrasive particles, grinding aid particles and resin matrix, and then filtering under pressure to obtain mortar;

[0081] (3) Putting glue sand: spraying the glue sand prepared in the surface coating step (2) on the pretreatment base cloth with the base cloth treatment liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com