A kind of high gas barrier thermoplastic vulcanizate and preparation method thereof

A thermoplastic vulcanizate and gas barrier technology, applied in the field of polymer materials, can solve the problems of high hardness of thermoplastic vulcanizate, and achieve the effects of enhanced bonding, harsh operating environment, and large solvent loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

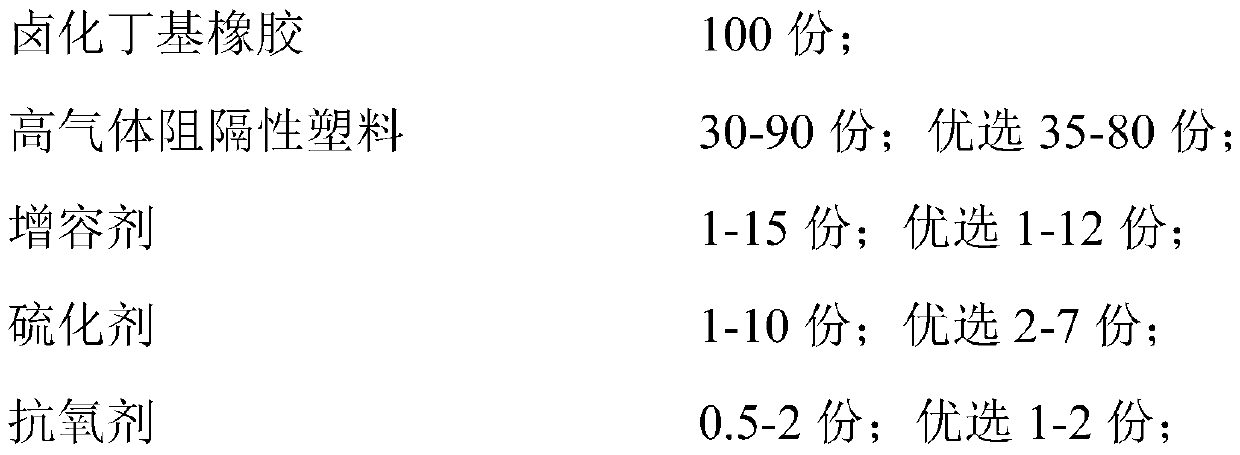

[0036] The basic composition and mass parts of the selected raw materials are as follows:

[0037]

[0038] Wherein the basic composition and mass fraction of the compatibilizer are as follows:

[0039]

[0040] According to the above formula, polyisobutylene, glycidyl methacrylate, styrene and dicumyl peroxide were put into a Rheocord Haake type batch mixer at room temperature, and pre-mixed for 15 minutes until the mixture was uniform, and then the mixture Put it into a mixing chamber preheated to the required temperature (set to 150°C), and mix for 12 minutes to obtain a low-molecular-weight polyisobutylene blend modified by glycidyl methacrylate; then add the compatibilizer and poly The amide was blended and grafted in an internal mixer at 200°C for 5 minutes, and the obtained product was dried and then mixed with bromobutyl rubber at 200°C, and an antioxidant was added, and the material was cooled to room temperature after mixing evenly; Mix uniformly with a vulcan...

Embodiment 2

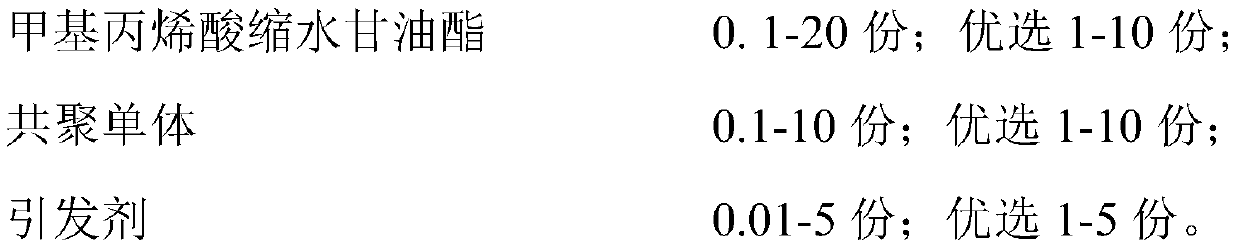

[0044] The basic composition and mass parts of the selected raw materials are as follows:

[0045]

[0046] Wherein the basic composition and mass fraction of the compatibilizer are as follows:

[0047]

[0048] According to the above formula, at room temperature, put medium molecular weight polyisobutylene, glycidyl methacrylate, acrylonitrile and di-tert-butyl peroxide into a Rheocord Haake type batch mixer, pre-mix for 12 minutes until the mixture is uniform, then Put the mixture into a mixing chamber preheated to the required temperature (set to 170° C.) and mix for 15 minutes to obtain a medium molecular weight polyisobutylene blend modified by glycidyl methacrylate; then add the compatibilizer Blending and grafting with polyamide 66 in an internal mixer at 200°C for 8 minutes, after drying the obtained product, mix it with brominated polyisobutylene-p-methylstyrene rubber at 190°C, add antioxidant, and mix evenly After discharging, the material is cooled to room t...

Embodiment 3

[0052] The basic composition and mass parts of the selected raw materials are as follows:

[0053]

[0054]

[0055] Wherein the basic composition and mass fraction of the compatibilizer are as follows:

[0056]

[0057] According to the above recipe, put low molecular weight polyisobutylene, glycidyl methacrylate, acrylic acid and dibutyl azobisisobutyrate into a Rheocord Haake type batch mixer at room temperature, and pre-mix for 18 minutes until the mixture is uniform , and then put the mixture into a mixing chamber preheated to the required temperature (set to 160°C) and mix for 15 minutes to obtain a low molecular weight polyisobutylene blend modified by glycidyl methacrylate; The compatibilizer and polyamide 12 were blended and grafted in an internal mixer at 200°C for 8 minutes, and the obtained product was dried and then mixed with chlorinated butyl rubber at 210°C, and an antioxidant was added. After mixing evenly, the material was discharged and cooled to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com