Belt slipping detecting method of belt conveyor and belt slipping detecting device of detecting method

A belt conveyor, belt slip technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of complex structure, power consumption, material accumulation, etc., to achieve high response frequency, low power consumption, failure Accurate effect of alarm signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

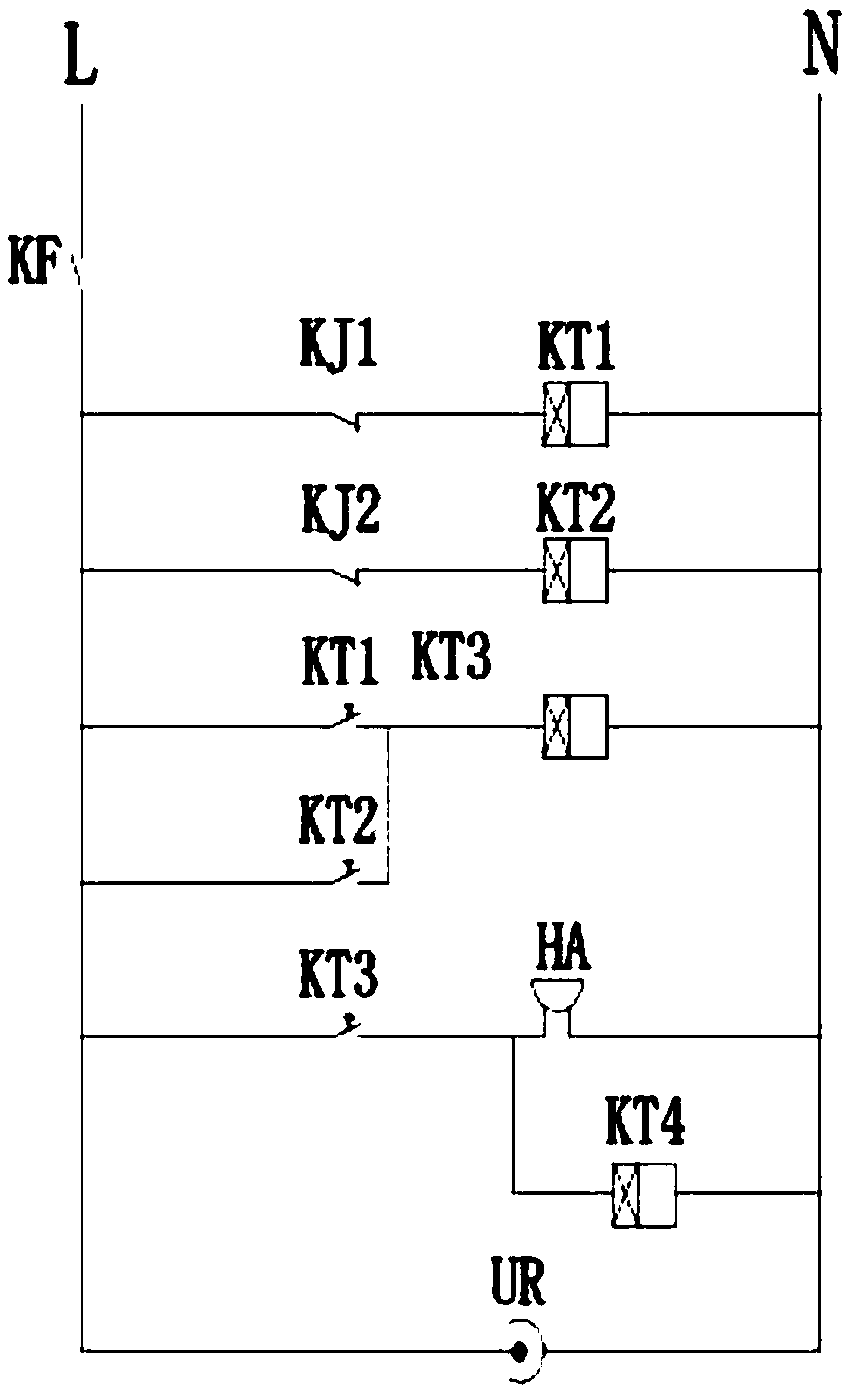

[0026] The belt slip detection method of the belt conveyor described in this embodiment adopts at least two groups of detection switches connected in parallel, each parallel circuit is connected with an intermediate relay, and a time relay is connected in the control circuit of each intermediate relay, and the completion The output switch signals of two groups of detection switches are detected within the time period t, and the output contacts of the time relay are connected to an alarm circuit.

[0027] In the belt slipping detection method of the belt conveyor, the detection switch adopts a Hall proximity switch, a travel switch, an infrared sensor switch or a capacitance sensor switch, and whether the output switch signal of the detection switch reflects the running state of the drive drum.

[0028] The belt slipping detection method of the belt conveyor of the present invention uses the conduction delay and power-off delay characteristics of the time relay to set a time per...

Embodiment 2

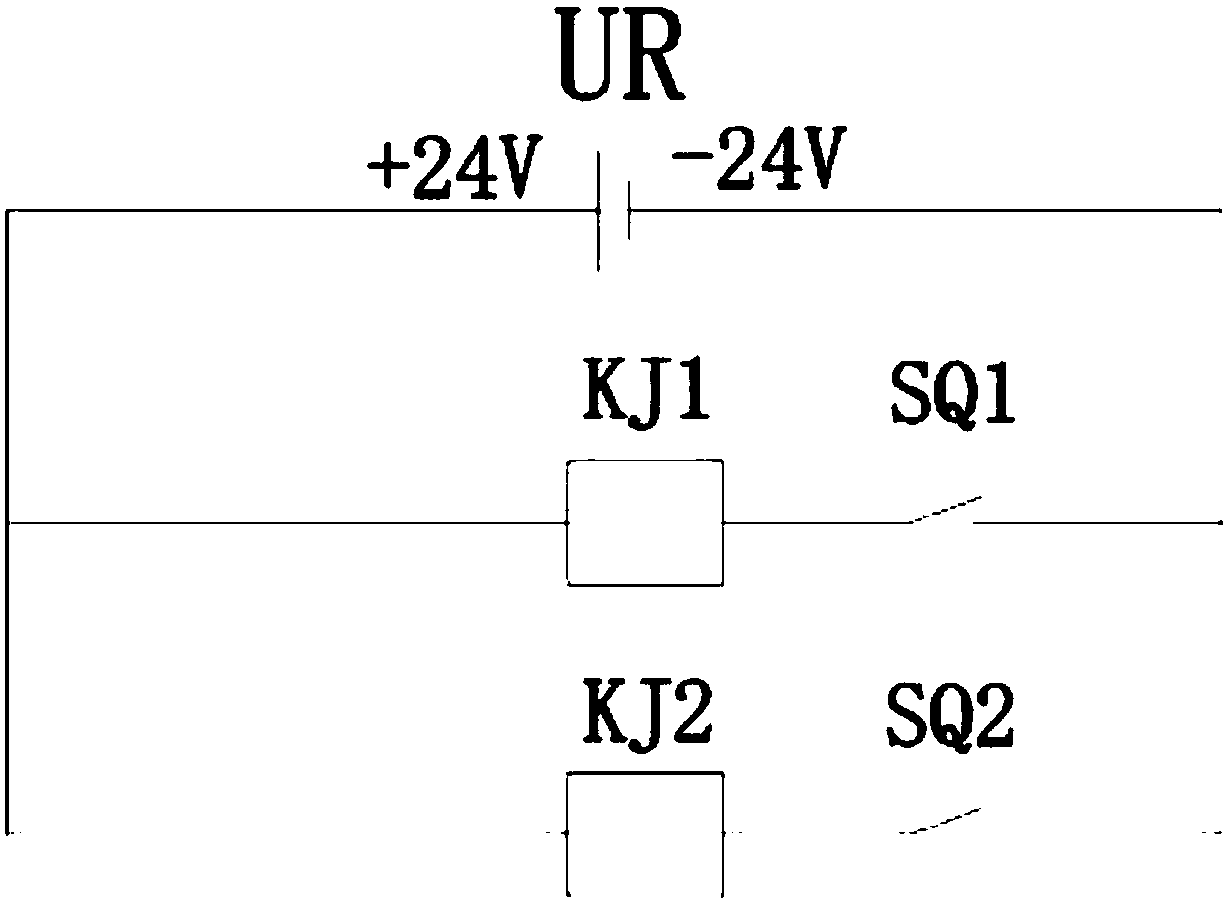

[0031] see figure 1 , figure 2 , Figure 4 . A belt slipping detection device, comprising a detection switch, a DC24V intermediate relay, a time relay, and an alarm. The detection switches are at least two groups, powered by a switching power supply, and an intermediate relay is connected to each group of detection switch circuits. A time relay is connected in an intermediate relay control circuit, the control switch of the time relay is connected in parallel, and a time delay relay control circuit is connected, and the control switch output signal of the time delay relay is connected to an alarm or a belt conveyor power-off control circuit . The block used in conjunction with the detection switch is set on the inner edge of one end of the belt conveyor drive roller, and the detection switch is fixed on the belt conveyor frame through the mounting support. The detection switch and the detection block The blocks correspond to and are distributed on the contour line of the ...

Embodiment 3

[0036] see Figure 1 ~ Figure 4 . The belt slipping detection device described in this embodiment includes a belt conveyor power-off control circuit, and the belt conveyor power-off control circuit includes a control relay and an intermediate relay, and the drive coil of the control relay is connected in parallel with the alarm. The control output signal of the control relay is connected to the intermediate relay in the power-off control circuit of the belt conveyor. Using the power-off delay characteristic of the time relay, the belt conveyor motor is powered off to achieve the control function.

[0037] image 3 KM is the intermediate relay of the motor control circuit.

[0038]In the belt slip detection device of the present invention, a baffle plate is fixedly installed on the inner edge of the belt drive drum, and a proximity switch is installed on the support of the drive drum, and the distance between the proximity switch and the baffle plate is 10-20mm. The time re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com