Organic electroluminescent device and preparation method and display device thereof

An electroluminescent device and luminescent technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as high triplet exciton concentration, device stability decline, triplet exciton annihilation, etc. , to achieve the effect of inhibiting molecular bond breakage, improving stability and reducing long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

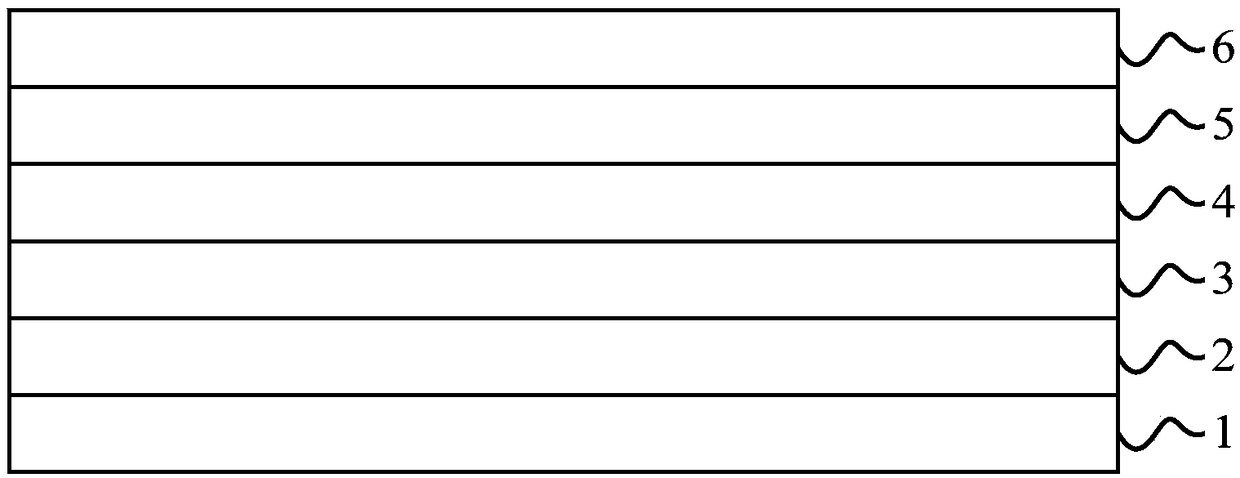

[0072] The present invention also provides a preparation method of the organic electroluminescent device, to figure 1 As an example, it includes sequentially depositing an anode 2 , a hole transport region 3 , a light emitting layer 4 , an electron transport region 5 , and a cathode 6 on a substrate 1 , and then packaging. Wherein, when preparing the light emitting layer 4, the light emitting layer 4 is formed by co-evaporating the triplet-triplet annihilation material source and the thermally activated delayed fluorescent material source.

[0073] Specifically, the preparation method of the organic electroluminescent device of the present invention comprises the following steps:

[0074] 1. Ultrasonically treat the glass plate coated with the anode material in a commercial cleaning agent, rinse in deionized water, ultrasonically degrease in acetone: ethanol mixed solvent, bake in a clean environment until the water is completely removed, and use ultraviolet light Light and o...

Embodiment 1-21

[0083] Embodiment 1-21 provides a kind of organic electroluminescent device respectively, and its device structure comprises ITO anode, hole injection layer (HIL), hole transport layer (HTL), light-emitting layer (EML), electron transport layer (ETL) successively. ), the electron injection layer (EIL) and the cathode.

[0084] Wherein, the material of the hole injection layer is HI-2, and the general total thickness is 5-30nm, which is 10nm in this embodiment. The material of the hole transport layer is HT-28, and the total thickness is generally 5-50 nm, which is 50 nm in this embodiment. The host material of the light-emitting layer is TTA material, the dye is TADF material, the doping concentration of the dye is 0.1-40wt%, and the thickness of the light-emitting layer is generally 1-60nm, which is 30nm in this embodiment. The material of the electron transport layer is ET-53, and the thickness is generally 5-30nm, which is 30nm in this embodiment. LiF (0.5nm) and metal al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com