A Method for Analyzing Hydrogen Supply Ability of Narrow Fraction of Petroleum Cracking Products

A technology for oil cracking and hydrogen supply capacity, applied in the fields of analysis materials, material separation, instruments, etc., it can solve the problems of cumbersome calculation process and not very intuitive, and achieve the effect of using less sample.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

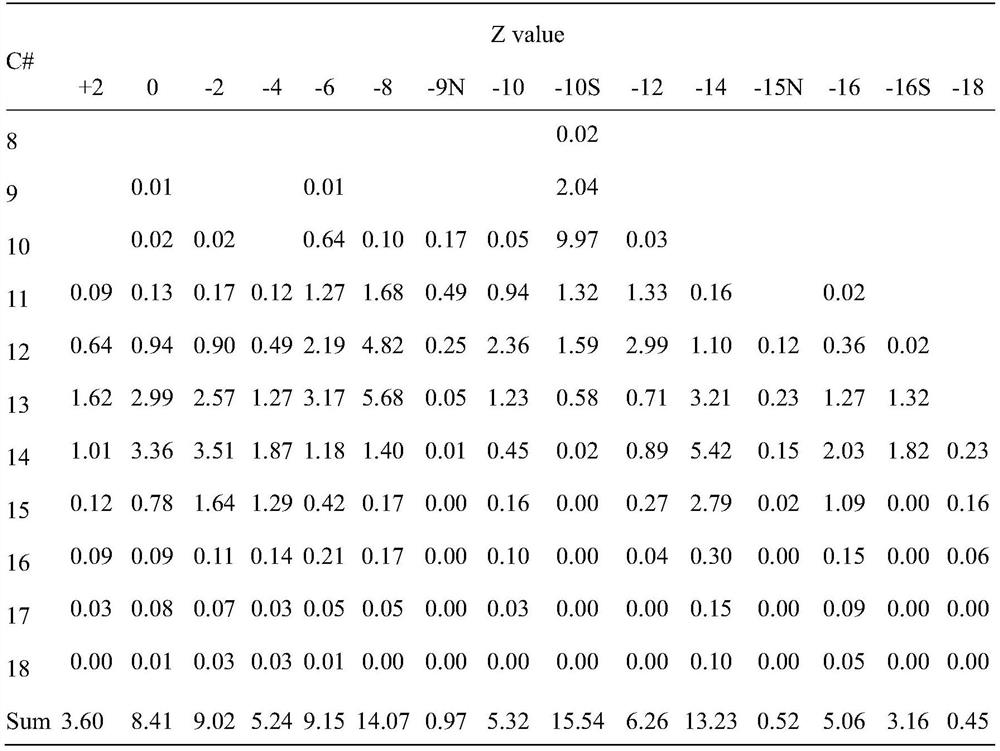

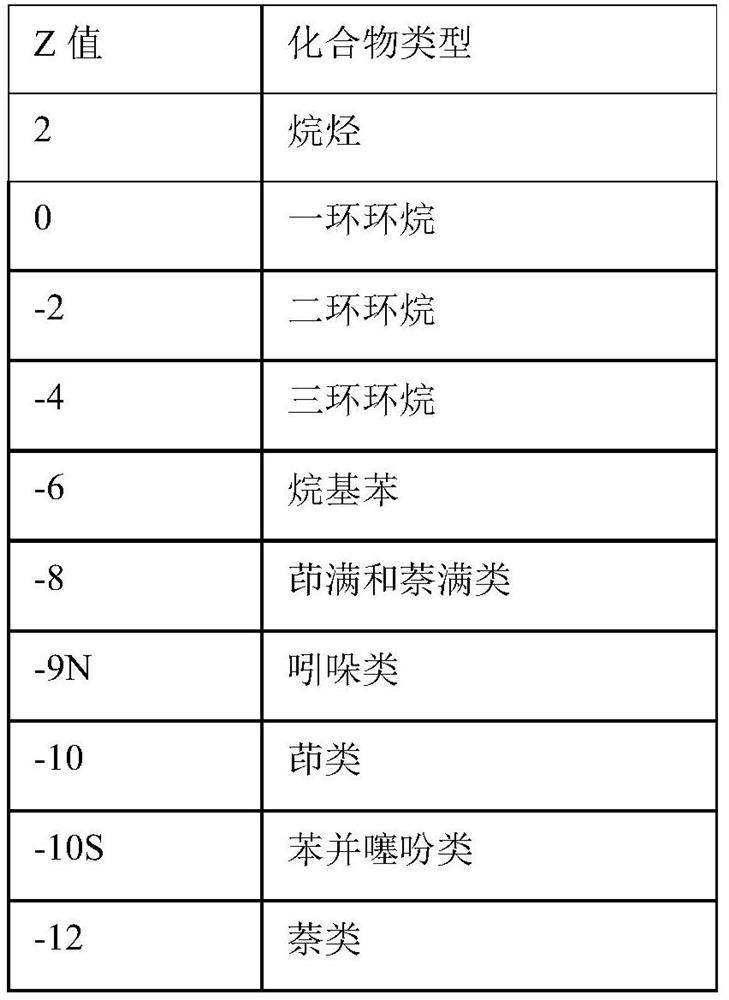

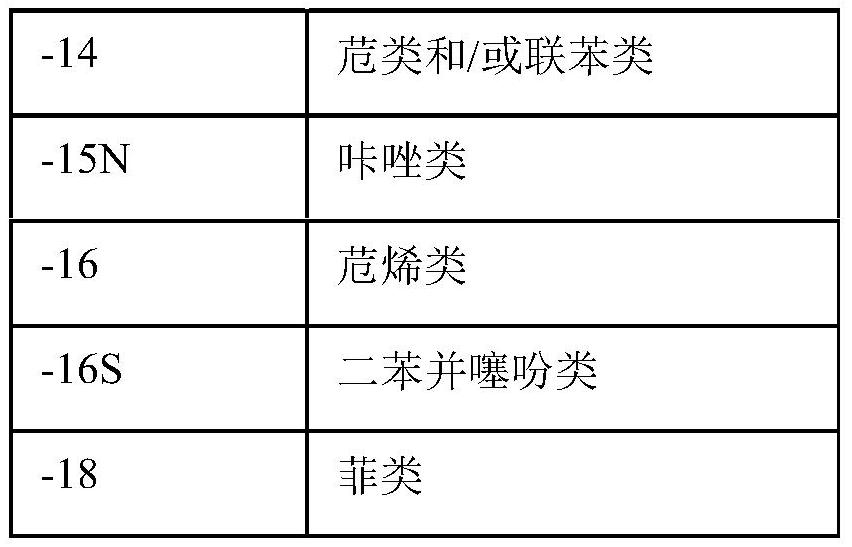

[0055] Distill and cut the cracked liquid product of Canadian oil sand bitumen residue (VTB) to obtain gasoline fraction (IBP-200°C, yield 13.6wt%), diesel fraction (200°C-350°C, 22.9wt%), light gas oil fraction (350°C-420°C, yield 9.10wt%) and heavy wax oil fraction (420°C-500°C, 12.1wt%) were analyzed as test samples to evaluate the hydrogen supply capacity of different fractions. Gasoline was directly analyzed by PONA column GC. The diesel fraction was directly analyzed by GC / FI-TOF-MS. Light wax oil and heavy wax oil adopt alumina as stationary phase respectively, take n-heptane and toluene as flushing solvent, are separated into light wax oil-saturated fraction (yield 36.4wt%) and light wax oil-aromatic fraction (yield 36.4wt%) Yield 63.6wt wt%), heavy wax oil-saturated fraction (yield 20.3wt%) and heavy wax oil aromatic fraction (yield 64.2wt%). After separation, the product was analyzed by GC / FI-TOF-MS. After data processing, the content of the compound in each fract...

Embodiment 2

[0057] The deoiled bitumen (DOA) cracking liquid product of Canadian oil sands bitumen residue (VTB) is distilled and cut to obtain gasoline fraction (IBP-200°C, yield 10.3wt%), diesel fraction (200°C-350°C, 14.5wt%) %), light wax oil fraction (350°C-420°C, yield 7.0wt%) and heavy wax oil fraction (420°C-500°C, 9.5wt%) were analyzed as test samples to evaluate the hydrogen supply capacity of different fractions . Gasoline was directly analyzed by PONA column GC. The diesel fraction was directly analyzed by GC / FI-TOF-MS. Light wax oil and heavy wax oil adopt alumina as stationary phase respectively, take n-heptane and toluene as flushing solvent, be separated into light wax oil-saturated fraction (yield 29.2wt%) and light wax oil-aromatic fraction (yield 29.2wt%) yield 63.9wt%), heavy wax oil-saturated fraction (yield 17.6wt%) and heavy wax oil aromatic fraction (yield 64.3wt%). After separation, the product was analyzed by GC / FI-TOF-MS. After data processing, the content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com