Pipe flow type coating material erosion resistance performance experiment device and method

A technology for coating materials and experimental devices, applied in measurement devices, analytical materials, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as low experimental efficiency, difficulty in controlling erosion angle and erosion speed, and complex experimental setups. , to achieve the effect of flexible and variable inclination angle, accurate and reliable experimental results, and flexible and diverse applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

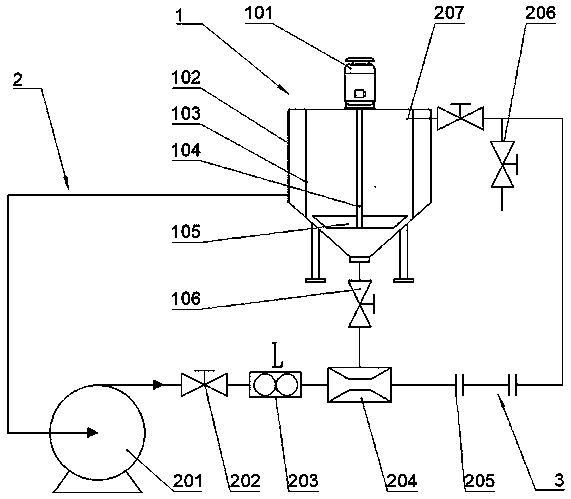

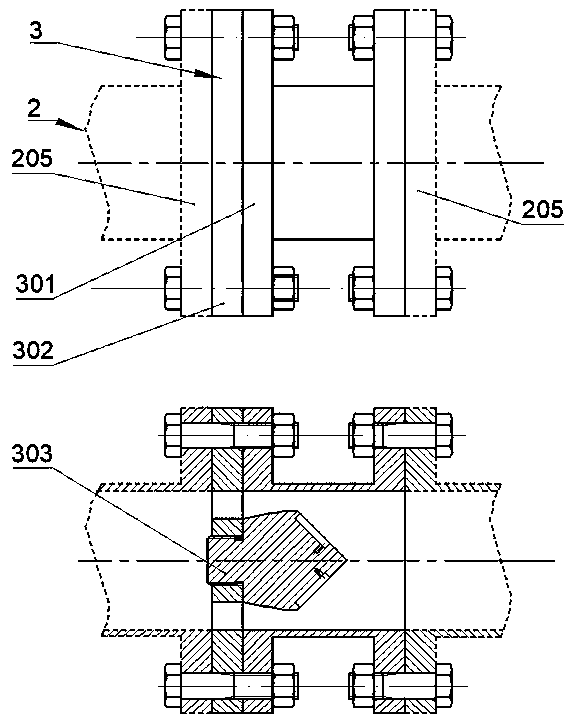

[0036] Such as Figure 1-4 As shown, the embodiment of the present invention provides a tube-flow type coating material erosion resistance test device, which includes: a solid phase supply module 1, a circulation line 2 and Tube flow erosion module3.

[0037]Wherein: solid phase supply module 1, it comprises motor 101, mixing box 102, columnar screen 103, transmission shaft 104, paddle 105 and control valve 106, and described columnar screen 103 is positioned at described mixing box 102 and with all The mixing box 102 is coaxially arranged, the bottom end of the columnar screen 103 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com