Equipment for observing directional solidification process in real time

A technology of directional solidification and equipment, which is applied in the field of equipment for real-time observation of the directional solidification process, can solve problems such as the difficulty in determining the influence of parameters, the inability to optimize the solidification process, and the inability to directly observe the growth of the eutectic solidification process, and achieve low cost and high-quality materials. Performance, the effect of less experimental consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

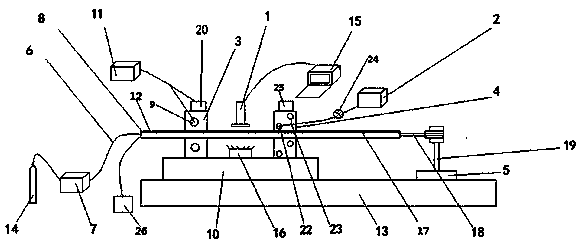

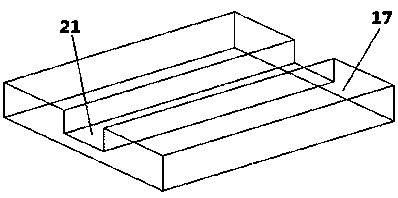

[0025] A device for real-time observation of directional solidification, such as figure 1 , 2As shown, it includes CCD microscope camera 1, constant temperature water tank 2, heating zone 3, cold zone 4, linear displacement stage 5, rubber tube 6, electronic pressure controller 7, glass container 8, heater 9, heat insulation plate 10, temperature Controller 11, pressure sensor 12, damping plate 13, gas cylinder 14, computer 15, cold light source 16, glass plate 17, connecting rod 18, support rod 19, temperature sensor I20, groove 21, water inlet 22, water outlet 23. Peristaltic pump 24, temperature sensor II 25, vacuum pump 26; heat insulation board 10 is placed on the shock absorber 13, the main component of heat insulation board 10 is nano-scale titanium silicate, and heat insulation board 10 is provided with cold light source 16, cold light source 16 two The heating zone 3 and the cold zone 4 are respectively arranged on the side. The heating zone 3 is composed of two uppe...

Embodiment 2

[0029] A device for real-time observation of the directional solidification process, using a motor to replace the linear displacement table 5, the motor is a linear motor, the speed of the motor is 0.10um / s, the output end of the motor is connected to the connecting rod 18, and the connecting rod 18 and the supporting rod 19 adopt Bearing connection, the bearing and the connecting rod 18 are clearance fit, the speed of the linear motor can be adjusted in the range of 0.005um / s~100um / s, the thickness of the glass plate 17 is 2.5mm, the depth of the groove 21 is 1.1mm, the glass container The thickness of 8 is 1 mm, the length of glass plate 17 is 18 cm, the length of groove 21 is 18 cm, the length of glass container 8 is 18 cm, and the distance between heating zone 3 and cold zone 4 is 3 cm; other components and the positions between components The relationship is the same as in Example 1.

[0030] The use method of the equipment in this embodiment is to put the sample into the...

Embodiment 3

[0033] A device for real-time observation of the directional solidification process, the thickness of the glass plate 17 is 2.2 mm, the depth of the groove 21 is 0.8 mm, the thickness of the glass container 8 is 0.7 mm, the length of the glass plate 17 is 15 cm, and the length of the groove 21 is 15cm, the length of the glass container 8 is 15cm, 2cm is separated between the heating zone 3 and the cold zone 4;

[0034] This embodiment studies the low melting point material carbon tetrachloride-hexachloroethane (CBr 4 -C 2 C 16 Alloy) solidification process, it is necessary to observe the solidification process of the material, put the sample into the glass container 8 through the trident tube, and then seal the gap and interface between the glass container and the rubber tube 6 with epoxy resin, and then turn on the vacuum pump 26 vacuumize the interior of the glass container 8, and the pressure sensor 12 shows that the pressure reaches 10 -2 pa, turn on the heater 9 to hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com