Process for improving plating thickness of zinc-nickel-plated low area

A coating thickness, zinc-nickel technology, applied in metal material coating process, coating, sputtering and other directions, can solve the problems of large thickness deviation in the high and low areas of the product, rough 84 plating, easy to powder, etc. Improve complexing ability, improve corrosion resistance, uniform and smooth thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

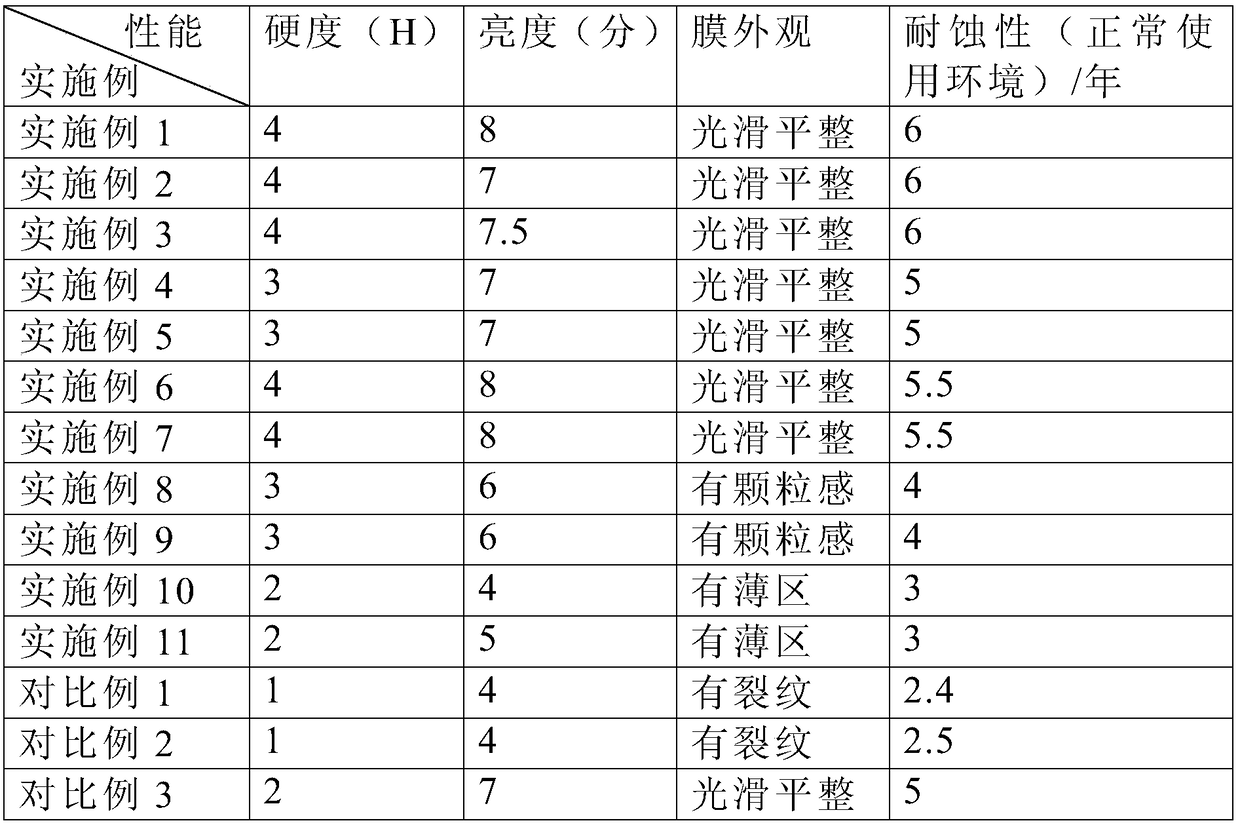

Examples

Embodiment 1

[0031] Pre-treatment: The alloy workpiece is degreased, hot water washed, rust removed, and cold washed in sequence. First, the alloy workpiece is tilted 20°, and superheated steam is continuously sprayed upward from the bottom of the workpiece for 30 seconds, then immersed in cold water at -2°C and circulated. Steam blowing, cold water immersion 3 times, and then soak the alloy workpiece with activator, wherein the activator includes hydrogen fluoride 45g / L, sodium fluoroborate 45g / L, perchloric acid 5g / L, ascorbic acid 4g / L, silicon carbide particles 50g / L, for physical and chemical compound activation treatment;

[0032] Membrane production: First, vapor-deposit metal magnesium on the activated alloy workpiece, put the alloy workpiece in hot water, boil, control the boiling time to 4min, take it out, dry it and immerse it in a sodium silicate solution containing 35g / L, set The temperature is 75°C, the pH is adjusted to 8, and the control time is 15 minutes to carry out seal...

Embodiment 2

[0035] Pretreatment: Carry out oil removal, hot water washing, rust removal, and cold water washing treatment on the alloy workpiece in sequence. First, the alloy workpiece is tilted 10°, and superheated steam is continuously sprayed upward from the bottom of the workpiece for 20 seconds, then immersed in -4 ℃ cold water, and circulated. Steam blowing and cold water immersion are performed twice, and then the alloy workpiece is soaked in an activator, where the activator includes 30g / L hydrogen fluoride, 40g / L sodium fluoroborate, 4g / L perchloric acid, 3g / L ascorbic acid, silicon carbide particles 40g / L, physical and chemical combined activation treatment;

[0036]Membrane production: First, vapor-deposit metal magnesium on the activated alloy workpiece, put the alloy workpiece in hot water, boil, control the boiling time to 4min, take it out, dry it and immerse it in a sodium silicate solution containing 35g / L, set The temperature is 75°C, the pH is adjusted to 8, and the con...

Embodiment 3

[0039] Pre-treatment: The alloy workpiece is degreased, hot water washed, rust removed, and cold washed in sequence. First, the alloy workpiece is tilted 30°, and superheated steam is continuously sprayed upward from the bottom of the workpiece for 40 seconds, then immersed in cold water at 0°C, and the steam is circulated. Spraying and soaking in cold water for 4 times, and then soak the alloy workpiece with activator, wherein the activator includes hydrogen fluoride 60g / L, sodium fluoroborate 50g / L, perchloric acid 6g / L, ascorbic acid 5g / L, silicon carbide particles 60g / L, for physical and chemical compound activation treatment;

[0040] Membrane production: First, vapor-deposit metal magnesium on the activated alloy workpiece, put the alloy workpiece in hot water, boil, control the boiling time to 4min, take it out, dry it and immerse it in a sodium silicate solution containing 35g / L, set The temperature is 75°C, the pH is adjusted to 8, and the control time is 15 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com