A kind of preparation method of ti6al7nb titanium alloy ingot

A titanium alloy and ingot casting technology is applied in the field of preparation of Ti6Al7Nb titanium alloy ingots, which can solve the problems of substandard mechanical properties, poor ingot composition uniformity, difficulty in meeting the clinical application requirements of medical materials, etc. Partially uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

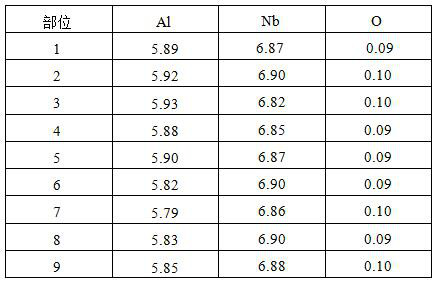

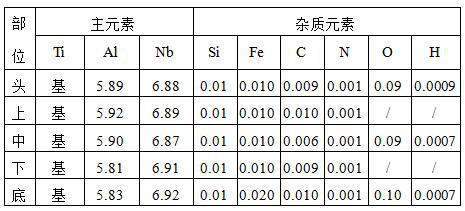

Examples

Embodiment 1

[0027] The invention provides a method for preparing a Ti6Al7Nb titanium alloy ingot, which is suitable for melting and preparing a Ti6Al7Nb titanium alloy ingot with a specification of Φ560-Φ720 mm, and specifically includes the following steps:

[0028] (1) Equipped with raw materials, select sponge titanium, AlNbTi alloy, Al beans and TiO 2 As a batching raw material, the batching is completed according to the ratio required by GB / T3620.1;

[0029] (2) mixing and pressing into an electrode block;

[0030] (3) Assembling and welding the electrode blocks in step (2) to obtain consumable electrodes;

[0031] (4) Carry out vacuum arc melting three times to the consumable electrode of step (3), and the melting process is controlled at vacuum degree 5.0Pa

[0032] Below, the smelting current is 30-40KA, the smelting voltage is 30-40V, and the cooling time after smelting is not less than 5 hours. The third vacuum consumable arc smelting adopts the melting speed control, and ente...

Embodiment 2

[0047] The present invention also provides a method for preparing a Ti6Al7Nb titanium alloy ingot, which is suitable for melting and preparing a Ti6Al7Nb titanium alloy ingot with a specification of Φ560-Φ720 mm, and specifically includes the following steps:

[0048] (1) Equipped with raw materials: the national standard sponge titanium, AlNbTi alloy, Al beans and TiO 2According to the proportion of Ti-6Al-7Nb-0.11O, the total weight of ingredients is 5500kg;

[0049] (2) Mixing materials and pressing them into electrode blocks: fully mix the raw materials prepared in step (1) evenly to complete the mixing, and use an 8000-ton hydraulic press to press them into electrode blocks with a pressing pressure of 35 MPa;

[0050] (3) vacuum plasma welding is carried out to the electrode block obtained in step 2 to obtain a consumable electrode;

[0051] (4) Carry out vacuum arc melting three times to the consumable electrode of step (3), specifically:

[0052] For the first vacuum ...

Embodiment 3

[0064] The present invention also provides a method for preparing a Ti6Al7Nb titanium alloy ingot, which is suitable for melting and preparing a Ti6Al7Nb titanium alloy ingot with a specification of Φ560-Φ720 mm, and specifically includes the following steps:

[0065] (1) Equipped with raw materials: the national standard sponge titanium, AlNbTi alloy, Al beans and TiO 2 According to the proportion of Ti-6Al-7Nb-0.11O, the total weight of ingredients is 5000kg;

[0066] (2) Mix the materials and press them into electrode blocks: fully mix the raw materials prepared in step (1) evenly to complete the mixing, and use an 8000-ton hydraulic press to press them into electrode blocks, and the pressing pressure is 32MPa;

[0067] (3) vacuum plasma welding is carried out to the electrode block obtained in step 2 to obtain a consumable electrode;

[0068] (4) Carry out vacuum arc melting three times to the consumable electrode of step (3), specifically:

[0069] For the first vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com