An integrated extraction method of multiple bioactive components in garlic

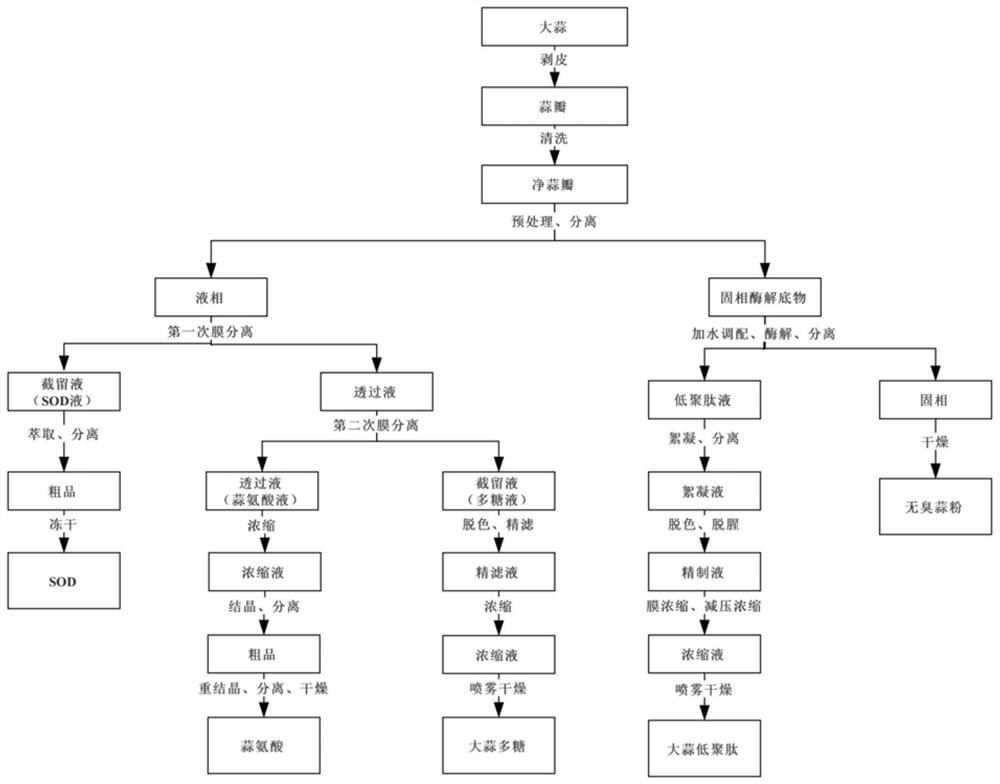

A bioactive component and extraction method technology, which is applied in the field of integrated extraction of various bioactive components in garlic, can solve the problems of poor taste, color and mouthfeel, unseparated extraction of bioactive components, and high production costs, so as to reduce the production cost. Pollution, less loss of active ingredients, and the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] S3. Preparation of SOD: the liquid phase obtained in the step S2 is passed through a ceramic membrane with a pore size of 20000Da (the first membrane separation), the permeate is used for standby, the retentate is collected, separated by acetone precipitation and freeze-dried to obtain SOD;

[0030] S4. Preparation of garlic polysaccharide: the permeate obtained by membrane separation for the first time in the step S3 is passed through an organic membrane with a pore size of 5000Da (membrane separation for the second time), and the permeate is used for subsequent use, and the retentate is collected for decolorization, Garlic polysaccharide was obtained by freeze-drying after concentration under reduced pressure;

[0031] S5. Preparation of alliin: the permeate obtained from the second membrane separation in the step S4 is concentrated under reduced pressure to a solid content of 15% to 30%, then dissolved in water after precipitation and separation, and recrystallized fr...

Embodiment 1

[0045] Garlic pretreatment: 100kg of garlic is peeled and washed to obtain about 91kg of garlic cloves, and the allinase is inactivated by heat treatment at 60°C for 20 minutes. Then, it was treated in a 4°C operating room, crushed the garlic cloves, added 100L of 0.5M NaCl solution pre-refrigerated at 4°C, used colloidal grinding, high-pressure homogeneous and wall-breaking treatment, and then added 0.5M NaCl solution to salt out the protein, etc. Precipitate until the solid content is 10%, and extract with stirring for 12 hours to obtain a mixed extract liquid. The mixed extraction feed liquid was separated by a decanter separator to obtain 150 L of liquid phase and 30 kg of solid phase enzymatic hydrolysis substrate.

[0046] Preparation of SOD: pass the 150L liquid phase obtained in the pretreatment step through a ceramic membrane with a pore size of 20,000Da (the first membrane separation), keep the permeate 120L for later use, collect about 30L of the retentate, add 30L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com