A method for the integrated extraction of multiple bioactive components in garlic dregs

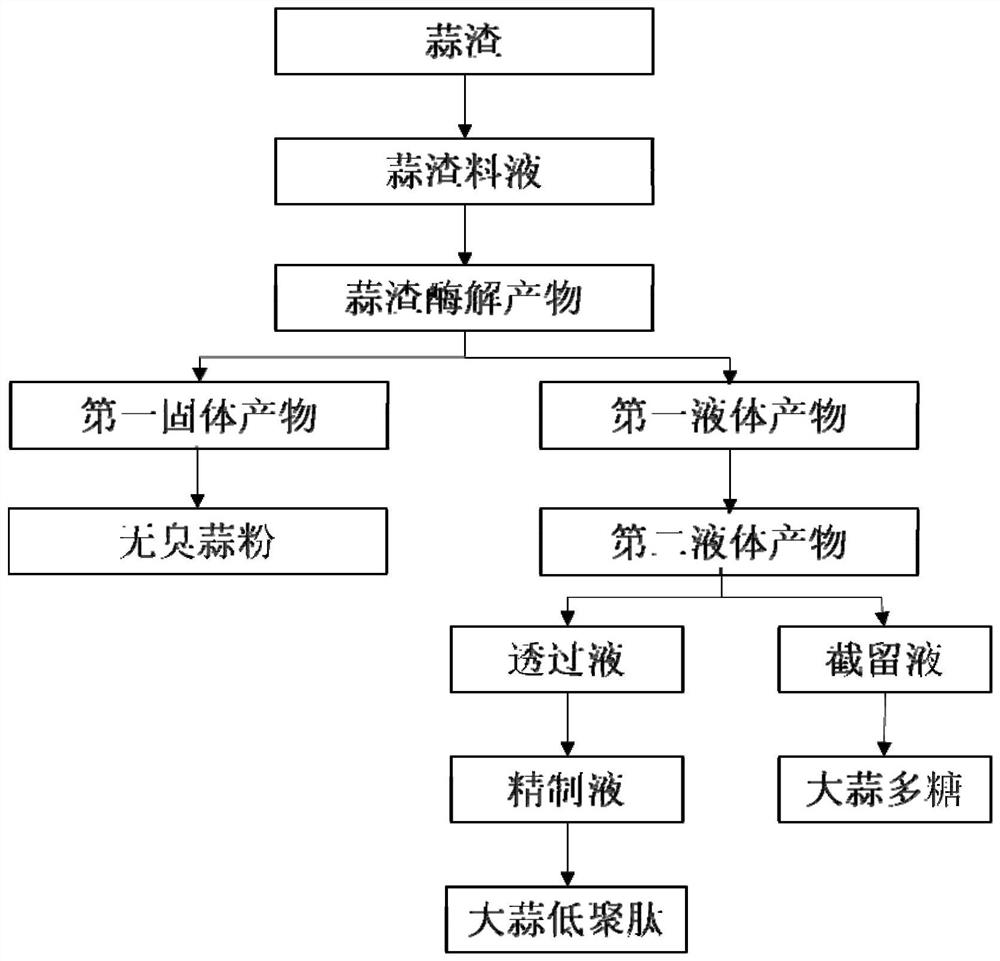

A technology of bioactive ingredients and garlic residues, which is applied in the field of integrated extraction of various bioactive ingredients in garlic residues, can solve the problems of unused active ingredients, and achieve the effects of ensuring stability, suitable enzymatic hydrolysis conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Mix 80kg of garlic dregs (waste dregs for producing garlic essential oil) with 800L of pure water to obtain a garlic dregs feed liquid, add 20% NaOH solution at 47°C to adjust the pH of the garlic dregs feed liquid to 8.0; use the garlic dregs feed liquid The total weight of the garlic protein is 100%, and 3% by weight of compound protease is added to the garlic residue feed solution for enzymolysis for 6 hours to obtain the garlic residue feed liquid after enzymolysis; wherein AS1.398 is neutral in the composite protease Protease (1×10 5 U / g), 2709 alkaline protease (2×10 5 U / g) and papain (6×10 5 The weight ratio of U / g) is 1:0.16:0.08. Add 3M HCl solution to the enzymatically hydrolyzed garlic residue feed solution to adjust the pH to 6.0 and heat up to 75°C to extinguish the enzyme for 30 minutes to obtain the garlic residue enzymatic hydrolyzate, centrifuge the garlic residue enzymatic hydrolyzate, and separate to obtain the first A solid product and a first liq...

Embodiment 2

[0041] Mix 200kg of garlic residue (the waste residue of garlic essential oil) with 3000L of pure water to obtain a garlic residue feed liquid, add 20% NaOH solution at 52°C to adjust the pH of the garlic residue feed liquid to 8.5; use the garlic residue feed liquid The total weight of the garlic protein is 100%, and 1% by weight of compound protease is added to the garlic residue feed solution for enzymolysis for 4 hours to obtain the enzymolyzed garlic residue feed liquid; wherein the AS1.398 neutral in the composite protease Protease (1×10 5 U / g), 2709 alkaline protease (2×10 5 U / g) and papain (6×10 5 The weight ratio of U / g) is 1:2:1.5. Add HCl solution with a concentration of 3M to the enzymatically hydrolyzed garlic residue feed liquid to adjust the pH to 7.0 and heat up to 85°C to inactivate the enzyme for 20 minutes to obtain the garlic residue enzymatic hydrolyzate, centrifuge the garlic residue enzymatic hydrolyzate, and separate to obtain the first A solid produ...

Embodiment 3

[0047] Mix 80kg of garlic dregs (waste dregs for producing garlic essential oil) with 800L of pure water to obtain a garlic dregs feed liquid, add 20% NaOH solution at 47°C to adjust the pH of the garlic dregs feed liquid to 8.0; use the garlic dregs feed liquid The total weight of garlic protein is 100%, and 3% by weight of compound protease is added to the garlic dregs feed solution for enzymolysis for 6 hours to obtain the enzymolyzed garlic dregs feed solution; wherein AS1.398 neutrality in the composite protease Protease (1×10 5 U / g), 2709 alkaline protease (2×10 5 U / g) and papain (6×10 5 The weight ratio of U / g) is 1:0.16:2. Add 3M HCl solution to the enzymatically hydrolyzed garlic residue feed solution to adjust the pH to 6.0 and heat up to 75°C to extinguish the enzyme for 30 minutes to obtain the garlic residue enzymatic hydrolyzate, centrifuge the garlic residue enzymatic hydrolyzate, and separate to obtain the first A solid product and a first liquid product.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com