Preparation method of high-solid epoxy abrasion-resistant coating

A wear-resistant coating and high-solid technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as environmental pollution, traditional coatings that are difficult to meet modern industry, and affect human health, so as to reduce production costs and improve production efficiency. Surface adaptability and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

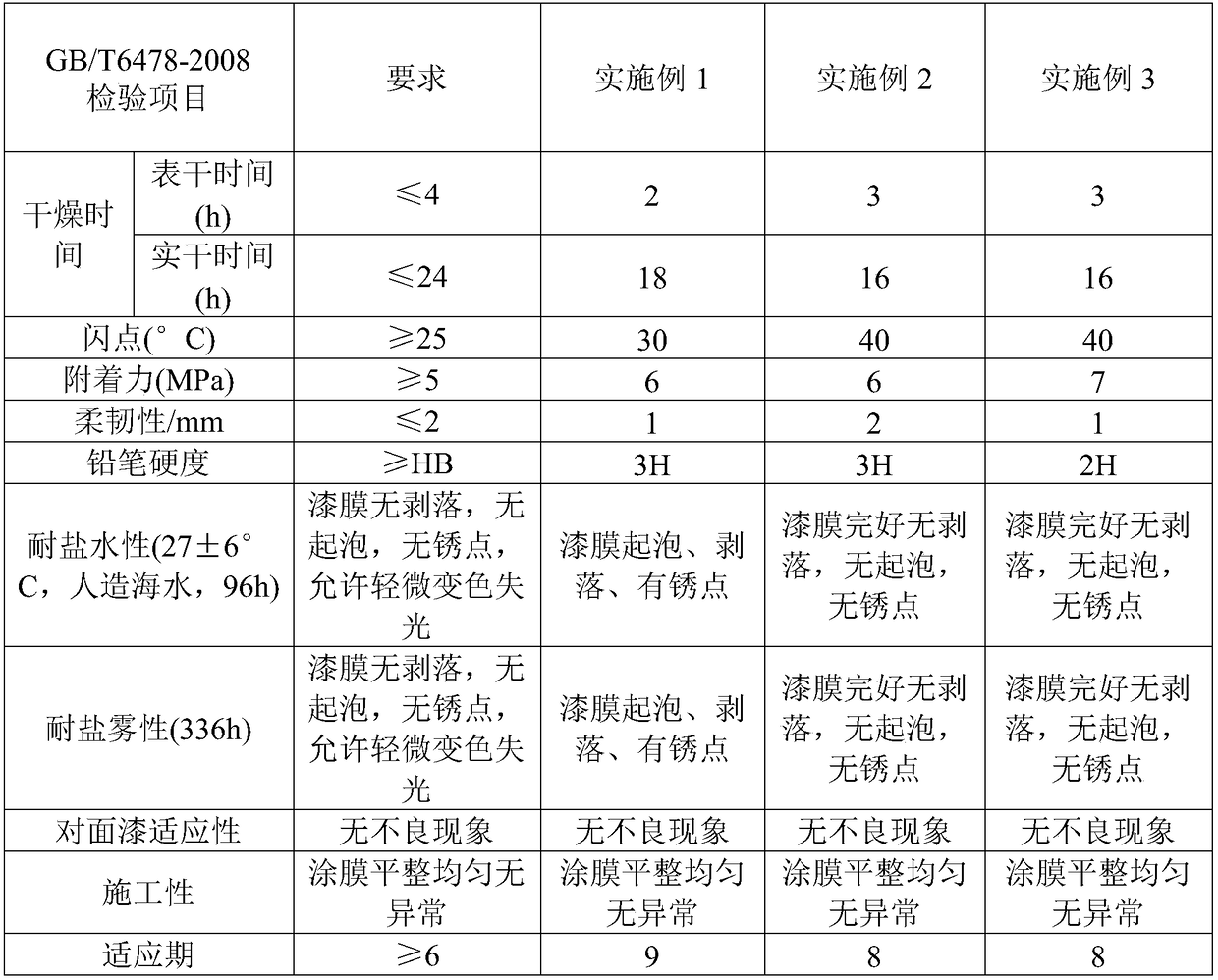

Embodiment 1

[0025] A preparation method of a high-solid epoxy wear-resistant coating created by the invention includes a main agent and a curing agent.

[0026] The main agent is prepared by the method comprising the following steps:

[0027] Step 1: Add 12.5 parts of epoxy resin 1, 5.5 parts of epoxy resin 2, 5.5 parts of reactive diluent, 2.7 parts of n-butanol, 7.0 parts of xylene, 2.0 parts of anti-settling agent, and 0.30 parts of dispersant into the reaction kettle in sequence , high-speed stirring to obtain a mixed solution.

[0028] Step 2: Under high-speed stirring, slowly add 12.5 parts of 600 mesh talc powder, 25.0 parts of feldspar powder, 9.0 parts of mica powder, and 2.0 parts of red iron oxide to the mixture in sequence, and stir for 30 minutes to make it fully mixed.

[0029] Step 3: Add 4.5 parts of epoxy resin 1, 0.8 parts of coupling agent, 4.55 parts of n-butanol, 1.5 parts of xylene, 2.0 parts of non-floating aluminum powder, 0.3 parts of dispersant, and 2.35 parts o...

Embodiment 2

[0033] The main agent is prepared by the method comprising the following steps:

[0034] Step 1: Add 29.5 parts of epoxy resin 1, 3.5 parts of epoxy resin 2, 3.0 parts of reactive diluent, 1.2 parts of n-butanol, 5 parts of xylene, 1.0 parts of anti-settling agent, and 0.1 parts of dispersant into the reaction kettle in sequence , high-speed stirring to obtain a mixed solution.

[0035] Step 2: Under high-speed stirring, slowly add 10.3 parts of 600 mesh talc powder, 15.0 parts of feldspar powder, 8.0 parts of mica powder, and 1.0 part of red iron oxide to the mixture in sequence, and stir for 30 minutes to make it fully mixed.

[0036] Step 3: Add 8.5 parts of epoxy resin 1, 0.6 parts of coupling agent, 2.41 parts of n-butanol, 0.5 parts of xylene, 4.0 parts of non-floating aluminum powder, 0.1 parts of dispersant, and 2.24 parts of xylene to the mixed solution, Disperse evenly after high-speed shearing, and make it into the main agent.

[0037] The curing agent is prepared...

Embodiment 3

[0040] The main agent is prepared by the method comprising the following steps:

[0041] Step 1: Add 20.36 parts of epoxy resin 1, 4.5 parts of epoxy resin 2, 4.0 parts of reactive diluent, 2.0 parts of n-butanol, 2.0 parts of xylene, 1.5 parts of anti-settling agent, and 0.15 parts of dispersant into the reaction kettle in sequence , high-speed stirring to obtain a mixed solution.

[0042] Step 2: Slowly add 7.3 parts of 600-mesh talc powder, 37.0 parts of feldspar powder, 5.0 parts of mica powder, and 1.5 parts of red iron oxide to the mixture under high-speed stirring, and stir for 30 minutes to make it fully mixed.

[0043] Step 3: Add 6.5 parts of epoxy resin 1, 0.7 parts of coupling agent, 2.61 parts of n-butanol, 0.5 parts of xylene, 3.0 parts of non-floating aluminum powder, 0.15 parts of dispersant, and 1.23 parts of xylene to the mixed solution, Disperse evenly after high-speed shearing, and make it into the main agent.

[0044] The curing agent is prepared by a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com