Structure and preparation method of an oil-resistant and bending-resistant mechanical equipment cable

A technology of mechanical equipment and cable structure, which is applied in the field of cable structure and preparation of oil-resistant and bending-resistant mechanical equipment, which can solve the problems of cable integrity damage, cable structure damage, and cable conduction decline, so as to improve corrosion resistance and bending resistance , strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

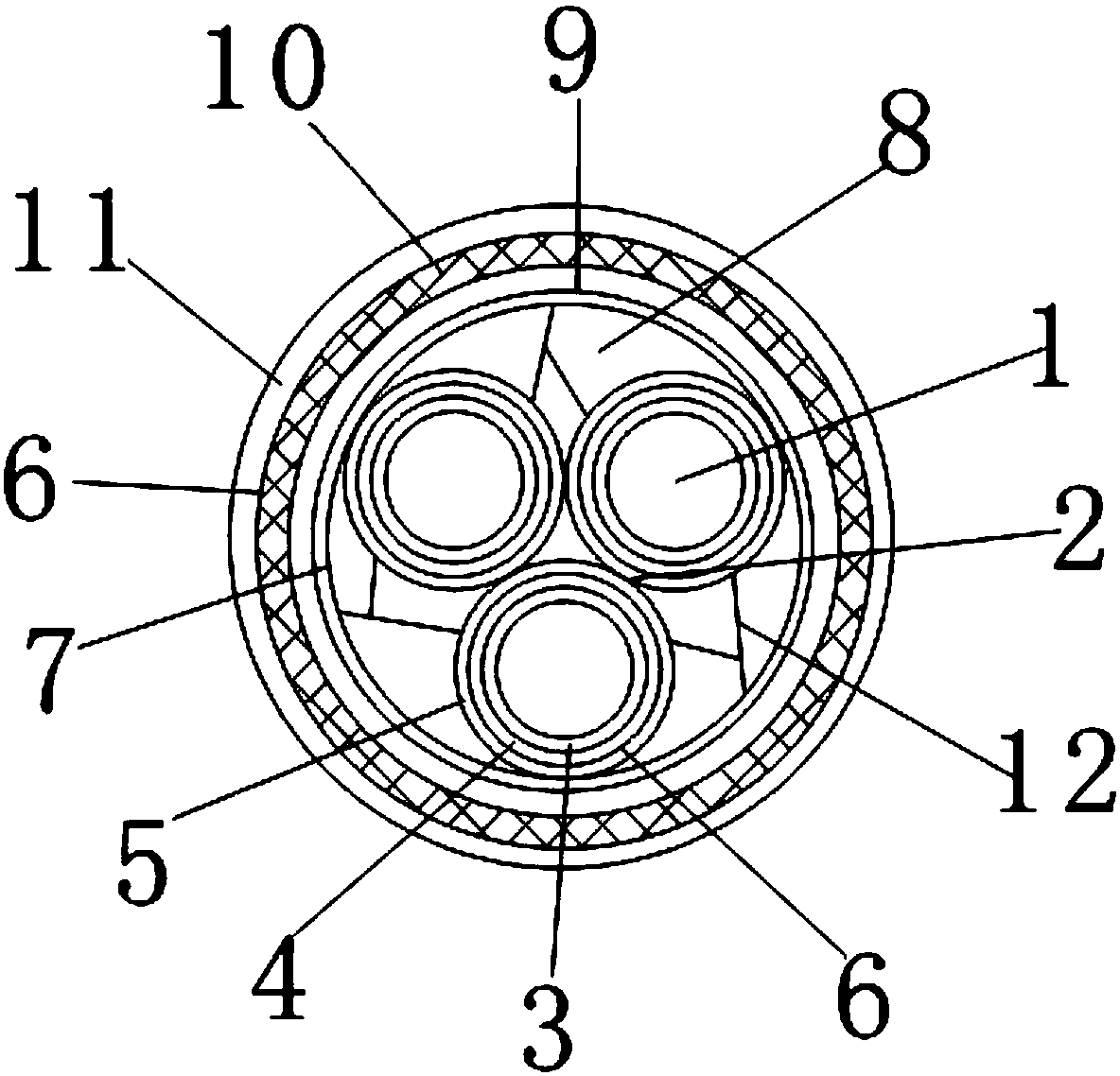

[0023] An oil-resistant and bending-resistant mechanical equipment cable structure, including a conductor wire 1, the number of the conductor wires 1 is three, and the three conductor wires 1 are helically twisted and connected together to form a single body 2, and the outer surfaces of the conductor wires 1 are in turn All are covered with a silica gel shielding layer 3, a fiber layer 4 and a rubber layer 5, and a PVC film 6 is added between the fiber layer 4 and the rubber layer 5, and the outer surface of the monomer 2 is covered with a two-dimensional fiber Silk layer 7, the two-dimensional fiber silk layer 7 is circular, and between the two-dimensional fiber silk layer 7 and the monomer 2 is filled with a semiconductive silicone rubber layer 8, the outer surface of the two-dimensional fiber silk layer 7 A reinforcing hoop 9 is fixedly installed on the top, and the outer surface of the reinforcing hoop 9 is provided with a non-woven fabric layer 10 and a silicone rubber she...

Embodiment 2

[0031] The difference from the above embodiment is that in the step (3), the pressure of the blister coating is 9 MPa. And when the silicone shielding layer, the semi-conductive silicone rubber layer and the silicone rubber sheath are all extruded through the sleeve die, the temperature of the extrusion head of the sleeve die is 85°C.

Embodiment 3

[0033] The difference from the above embodiment is that in the step (3), the pressure of the blister coating is 10 MPa. And when the silicone shielding layer, the semi-conductive silicone rubber layer and the silicone rubber sheath are all extruded through the sleeve die, the temperature of the extrusion head of the sleeve die is 90°C.

[0034] The effects of blister pressure, extrusion temperature, etc. on the properties were studied by the following tests.

[0035] project

Blister pressure

extrusion temperature

oil resistance

Bending times

Anti-bending curvature

Productivity

Standard

-

-

Difference

Difference

Difference

generally

Example 1

8MPa

80℃

better

better

better

high

Example 2

9MPa

85℃

it is good

it is good

it is good

high

Example 3

10MPa

90℃

it is good

better

it is good

high

[0036] From the above table, we can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com