Method for manufacturing micro-channel rapidly on basis of 3D printing

A technology of three-dimensional printing and micro-channels, which is applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of low precision of micro-channels, complex process, high cost, etc., and achieve good packaging effect , simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

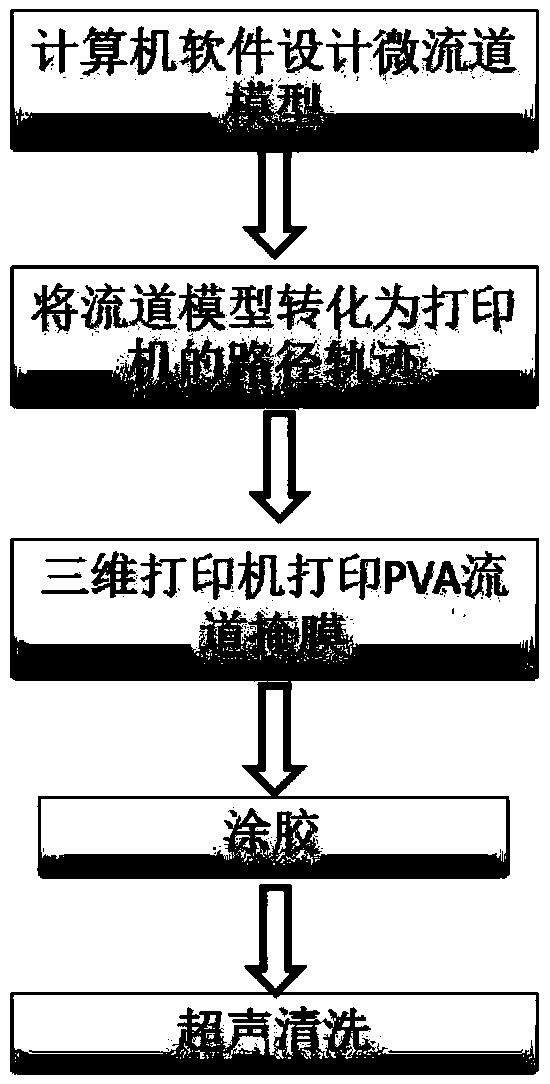

[0037] figure 1 It is a process flow diagram of the present invention, a method for rapidly manufacturing microchannels based on three-dimensional printing, comprising the following steps:

[0038] (1) Using the computer-aided design software solidworks to design the model of the Y-shaped microchannel, and design a boss at the end of the channel.

[0039] (2) Then save the model as stl file format, import it into the slicing software, generate the printing path trajectory of the 3D printer, copy the generated gcode file to the 3D printer, and prepare for printing.

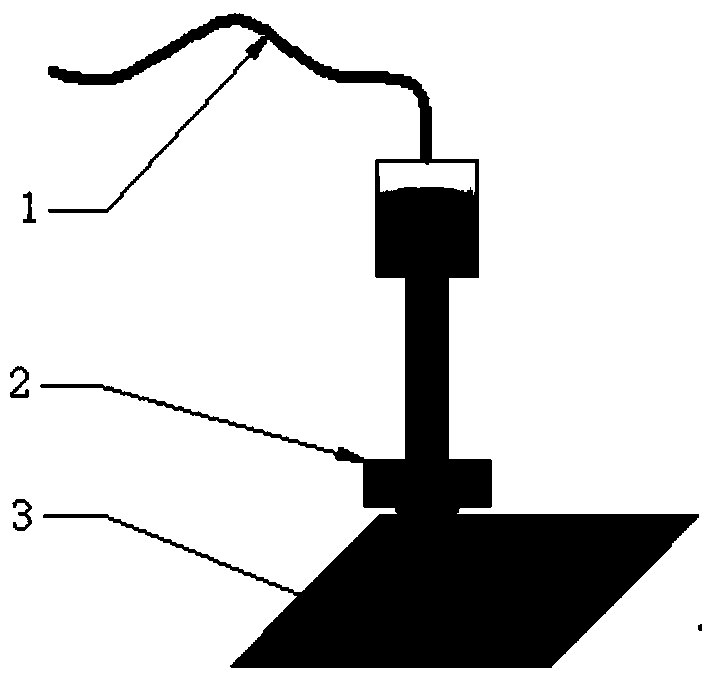

[0040] (3) The printing material is PVA water-soluble filament, such as figure 2 shown, figure 2 Schematic diagram of the 3D printing process. Among them, 1-PVA wire, 2-printing nozzle, 3-printing substrate. Using an FDM printer, polyvinyl alcohol (PVA) was printed on the printing substrate polymethyl methacrylate (PMMA) according to the designed track to form a PVA flow channel mask with a width of 200 μm. ...

Embodiment 2

[0044] (1) Use the computer-aided design software solidworks to design the model of the curved micro-channel, and design the boss at the end of the channel.

[0045] (2) Then save the model as stl file format, import it into the slicing software, generate the printing path trajectory of the 3D printer, copy the generated gcode file to the 3D printer, and prepare for printing.

[0046] (3) The PVA water-soluble material is printed on the printing substrate polyethylene terephthalate (PET) according to the design track by using the FDM type printer to form a PVA flow channel mask with a width of 300 μm.

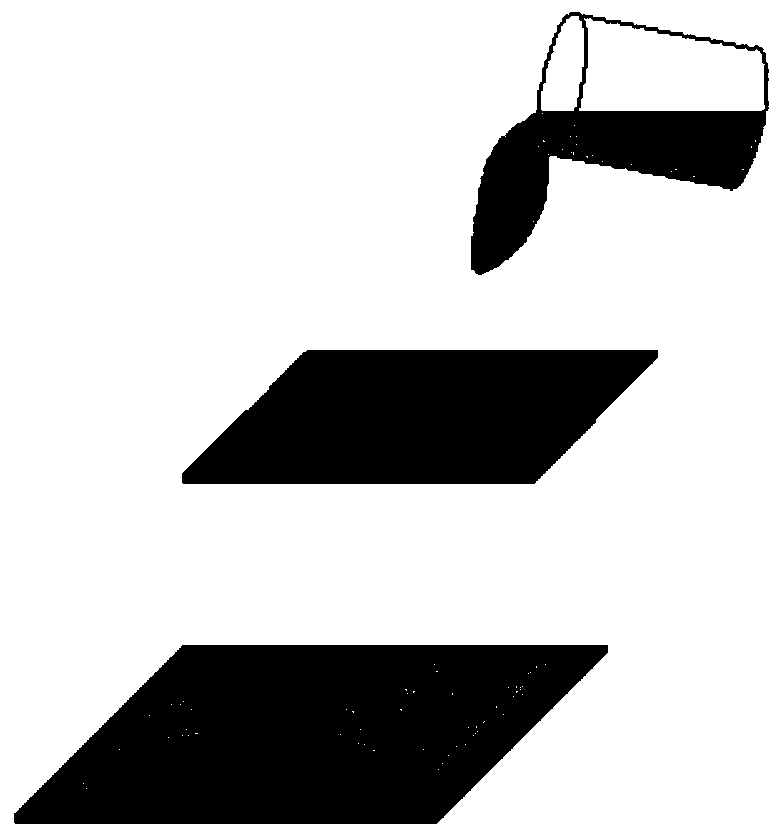

[0047] (4) After removing the printing substrate on which the PVA runner mask is deposited, pour the UV-curable adhesive Lantian 9307 onto the PET of the printing substrate to completely cover the runner, but do not miss the boss at the end of the runner.

[0048] (5) After the glue is cured, put the entire microfluidic chip into a cleaning machine with ultrasonic power of 50 k...

Embodiment 3

[0050](1) Using the computer-aided design software solidworks to design a model of a single annular microchannel, and design a boss at the end of the channel.

[0051] (2) Then save the model as stl file format, import it into the slicing software, generate the printing path trajectory of the 3D printer, copy the generated gcode file to the 3D printer, and prepare for printing.

[0052] (3) Using an FDM printer to print the PVA water-soluble material on the glass of the printing substrate according to the design track, to make a PVA flow channel mask with a width of 250 μm.

[0053] (4) After removing the printing substrate on which the PVA runner mask is deposited, pour the epoxy resin AB glue on the glass of the printing substrate to completely cover the runner, but do not miss the boss at the end of the runner.

[0054] (5) After the glue is cured, put the entire microfluidic chip into a cleaning machine with ultrasonic power of 40 kHz and water temperature of 80 °C for 9 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com