Quasi-shear mode multilayer co-fired piezoelectric actuator and its preparation method

A technology of piezoelectric actuators and actuators, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., to achieve the effect of small device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

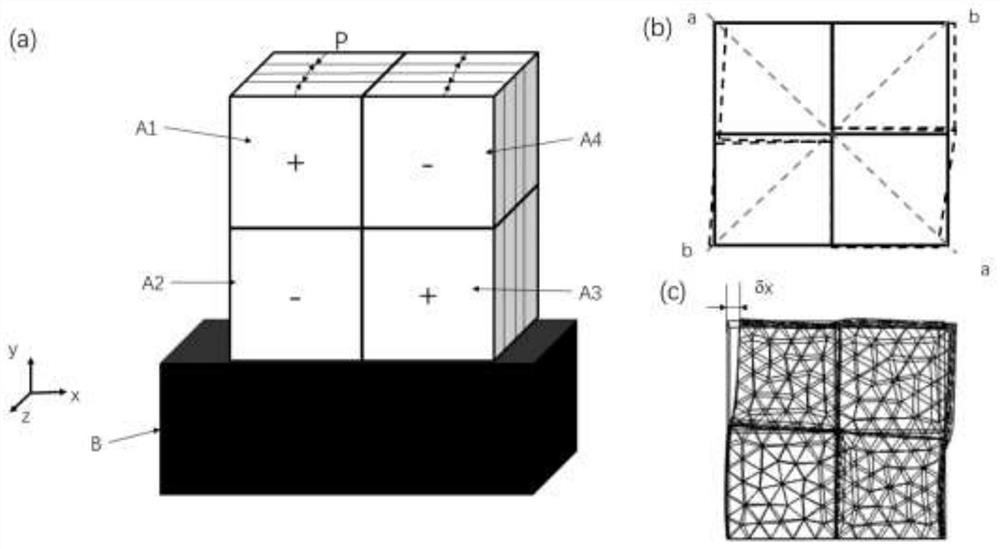

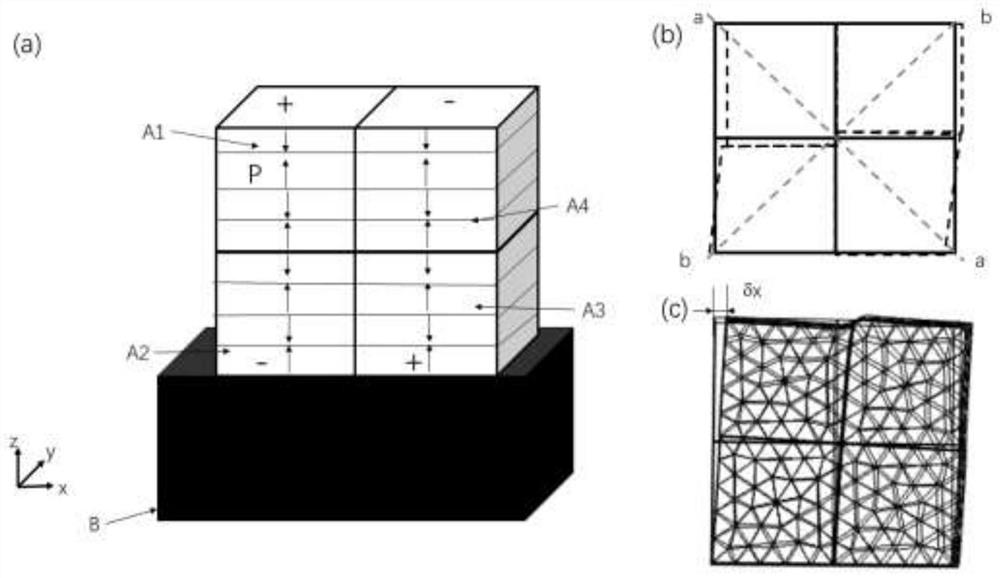

[0034] The multilayer "quasi-shear" mode piezoelectric actuator structure includes: (i)d 36 mode "quasi-shear" actuator, (ii)d 35 mode "quasi-shear" actuators, and (iii)d 34 mode "quasi-shear" actuator.

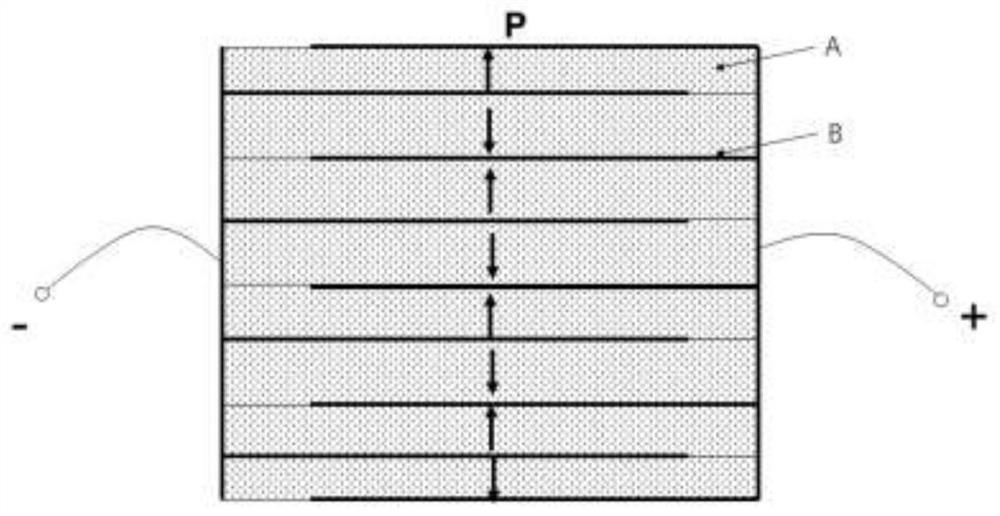

[0035] The four driving units in the multilayer co-fired actuator have respectively set polarization direction, multilayer structure arrangement direction and voltage application direction; among them, each driving unit is a multilayer piezoelectric ceramic structure with internal electrodes ,Such as figure 1 shown.

[0036] The first is d 36 mode quasi-shear multilayer co-fired structure actuator, see figure 2 (a); The actuator is divided according to the electrodes, which can be seen as consisting of four d 31 mode drive unit; each drive unit is also a small multilayer structure, arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com