Curing device and method for internal cooling and humidification of mass concrete

A large-volume concrete and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of concrete humidification and maintenance, achieve good maintenance effect, improve utilization rate, and improve humidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

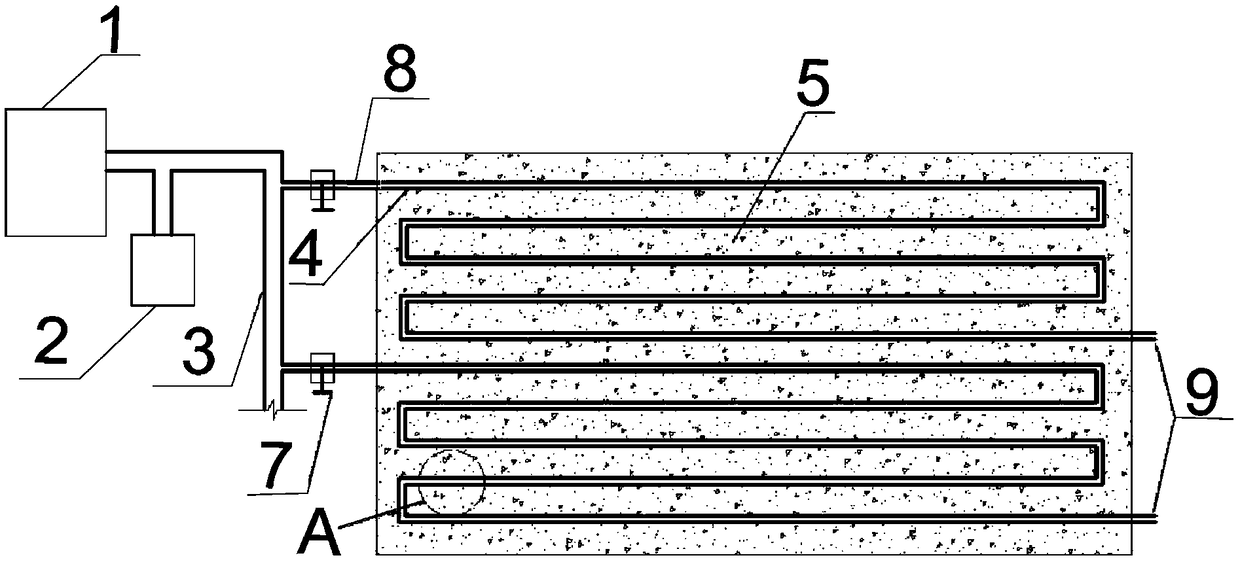

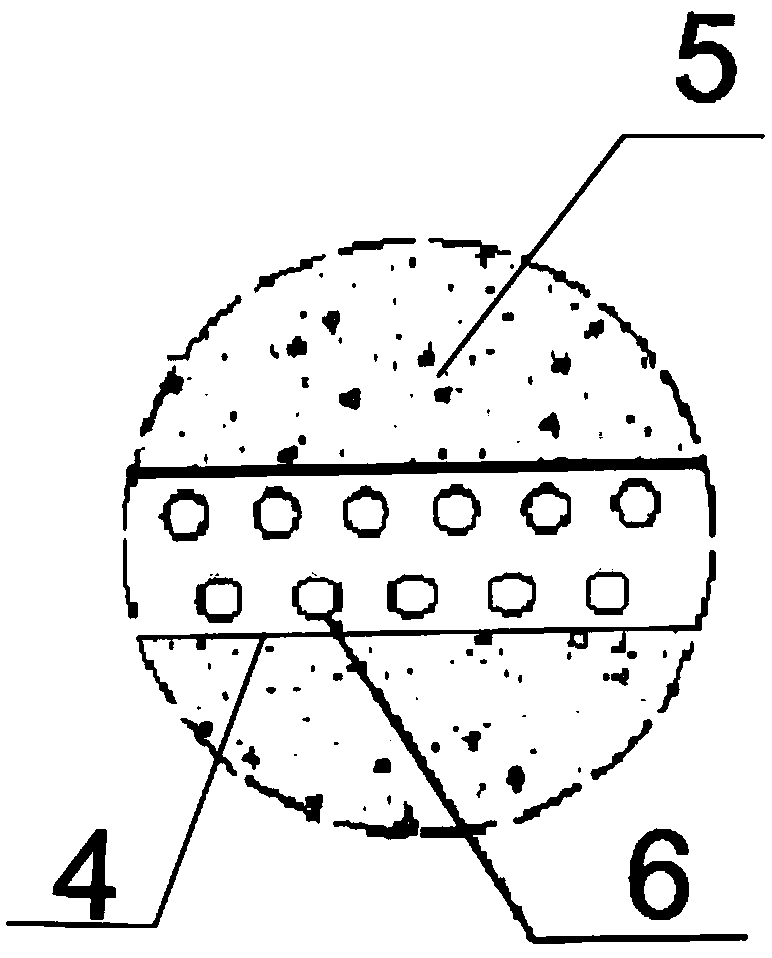

[0038] Such as Figure 1-2 As shown, a maintenance device for mass concrete internal cooling and humidification in this embodiment includes an air refrigerator 1, an atomizer 2 and a cold air pipeline; the cold air pipeline includes a main cold air pipeline 3 and a plurality of uniformly pre-buried in The cold air buried pipe 4 in the concrete 5, the air outlet of the air refrigerator 1 and the mist exhaust port of the atomizer 2 are connected with the cold air main pipe 3, and the cold air main pipe 3 is connected to multiple cold air buried pipes 4 at the same time, and the cold air buried pipe inlet 8 A control valve 7 is set; a plurality of ventilation holes 6 are set on the pipe wall of the cold air buried pipe 4 . The cold air buried pipe outlet 9 is located outside the concrete. The nebulizer adopts a high-power ultrasonic nebulizer. Refrigeration equipment adopts industrial air conditioners, and its power is customized according to the construction progress. The wet...

Embodiment 2

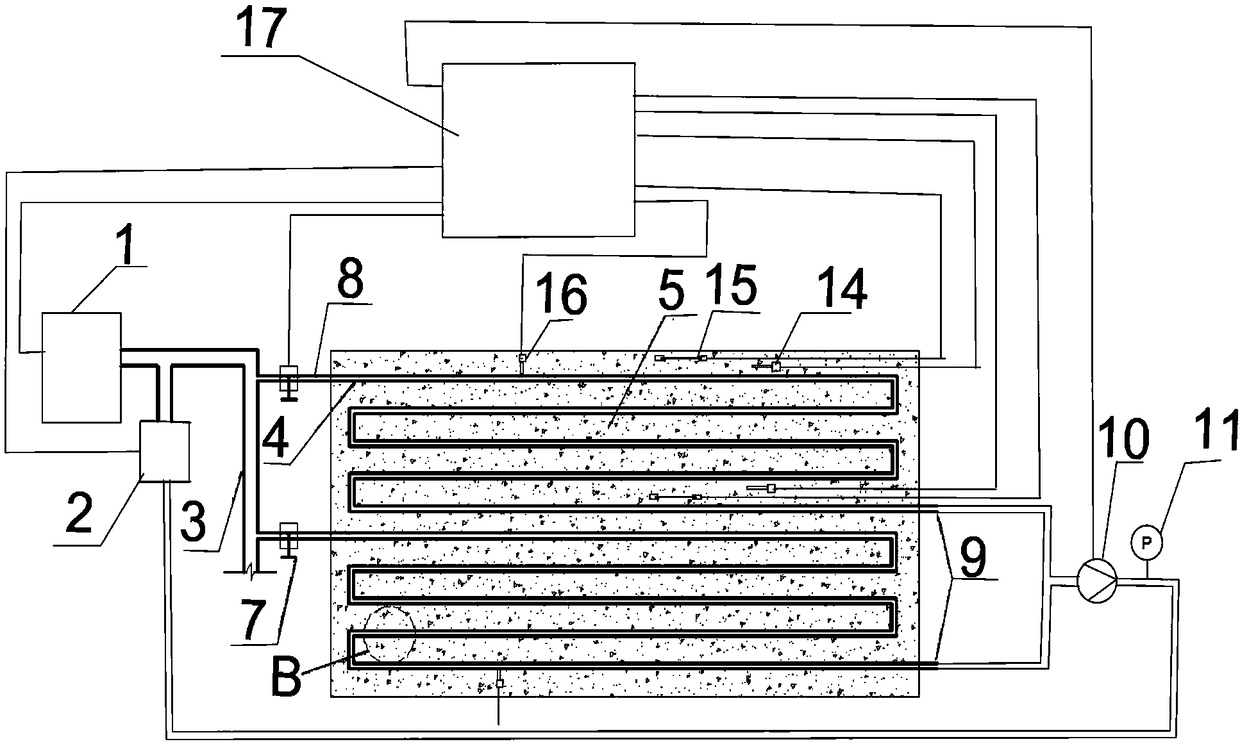

[0041] Such as Figure 3-4 As shown, compared with Embodiment 1, the cold gas buried pipe outlet 9 of this embodiment is connected to a vacuum pipeline, and a vacuum pump 10 and an electronic vacuum gauge 11 are arranged on the vacuum pipeline. The outlet of the vacuum pump 10 is connected to the air inlet of the atomizer 2 . The inner wall of the buried cold air pipe 4 is provided with a breathable anti-blocking retaining ring 12 . A plurality of moisturizing rings 13 are arranged in the inner wall of the cold air buried pipe 4, and the plurality of moisturizing rings 13 are evenly arranged along the length direction of the cold air buried pipe; A plurality of temperature sensors and humidity sensors are fixedly arranged on the periphery of the concrete 5 and on the internal steel bars. The temperature and humidity sensor is an integrated probe type temperature and humidity sensor 14 . A plurality of stress sensors 15 are fixedly arranged on the outer and inner steel bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com