Method for recycling bromine from bromine containing waste water

A wastewater recovery and bromine technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large number of equipment, complicated process, explosion, etc., to avoid poisonous and harmful, The effect of reducing bromine consumption and occupying a small area of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

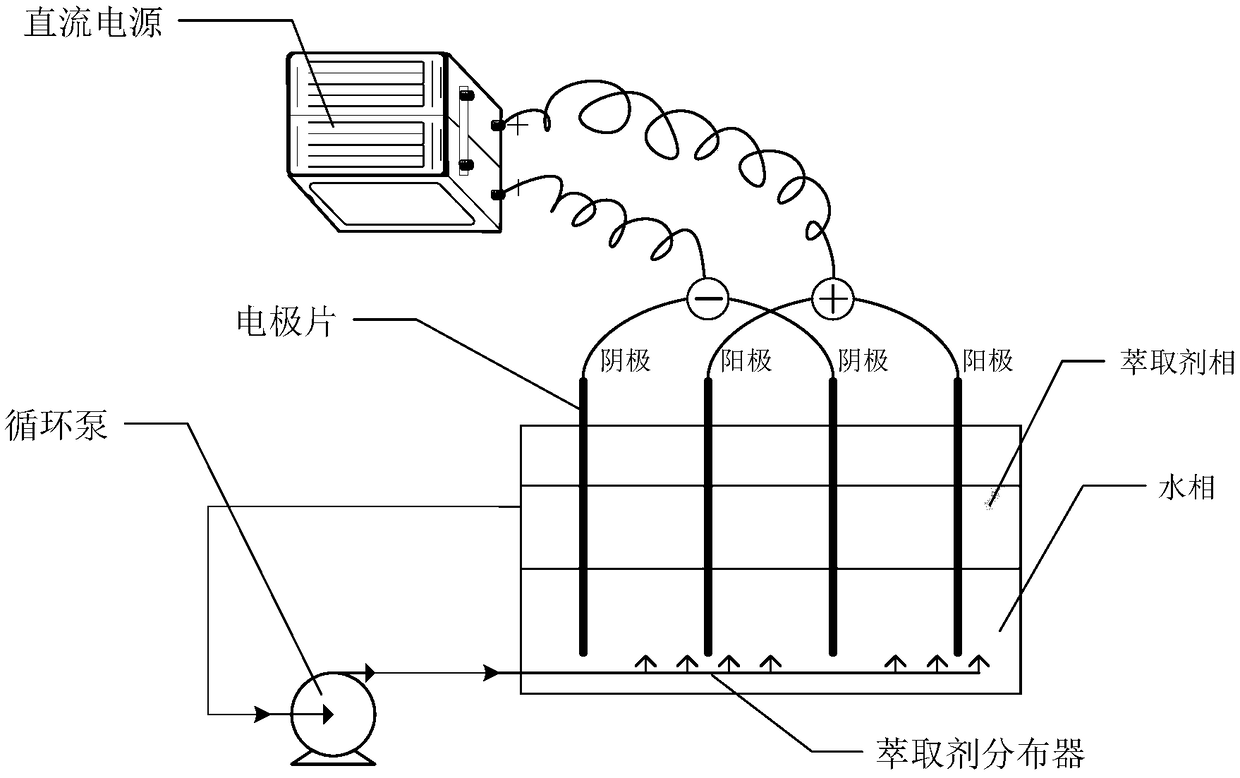

[0036] The electrolysis device used in the electrolytic treatment of bromine-containing wastewater in this embodiment is as follows: figure 1 As shown, it mainly includes a DC power supply, a 1.0L electrolyzer, four titanium electrode sheets, and a peristaltic pump for extractant circulation. The flow rate of the peristaltic pump is adjustable. The titanium electrode is a 8.0cm×20.0cm rectangular titanium plate with a thickness of 1.0mm, and the surface is coated with a ruthenium oxide coating, which can effectively prevent corrosion during the electrode oxidation reaction. During the electrolysis process, the phase-separated extracted oil phase can be pumped to the distributor arranged in the anode area through the oil phase circulation pump, and the dispersed oil phase extractant can quickly extract the bromine element generated by electrolysis into the oil phase in the anode area to realize Br 2 enrichment separation.

[0037]The bromine-containing wastewater treated in th...

Embodiment 2

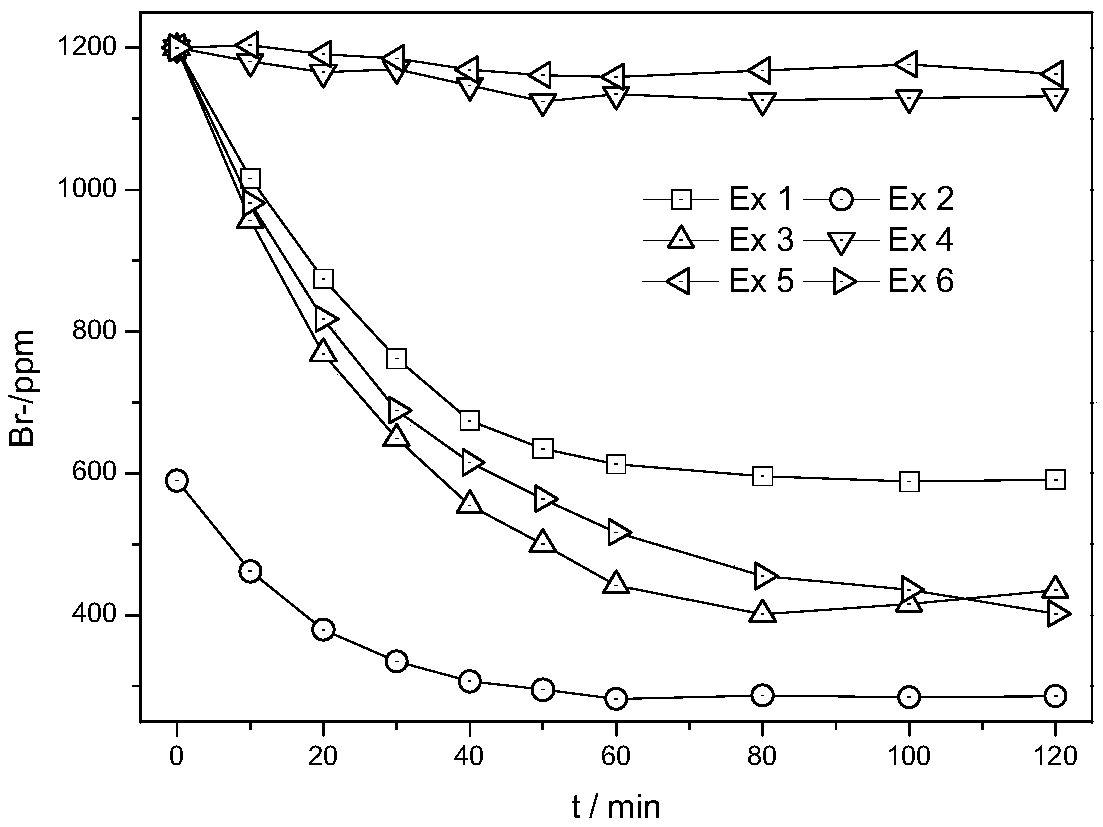

[0041] The electrolytic treatment of bromine-containing wastewater was carried out in a manner similar to that of Example 1. The PTA bromine-containing wastewater after electrolytic treatment in Example 1 was used for 2 hours to continue electrolytic treatment, and its Br content was 590 ppm. Firstly separate the PX phase with bromine elemental substance extracted, add sulfuric acid to adjust the pH value of the water phase to 3.0, then add 200ml of fresh PX as the extraction agent, and circulate the upper oil phase to the distributor in the anode area for extraction by a peristaltic pump. The flow rate of the peristaltic pump is 20ml / min. Turn on the power, adjust the voltage and maintain a stable current of 0.8A to carry out the electrolysis reaction. It can be observed that a large number of bubbles are generated on both the anode plate and the cathode plate. The oil phase PX gradually deepens as the electrolysis progresses, which also shows that the electrolysis process ha...

Embodiment 3

[0043] Carry out the electrolysis treatment of bromine-containing wastewater in a manner similar to Example 1, and the bromine-containing wastewater that is used is also the PTA wastewater described in Example 1, and the PX extractant. The difference is that in this embodiment, a plate-type graphite electrode (8.0 cm×20.0 cm) is used instead of a titanium electrode, and sulfuric acid is added to adjust the pH value to 2.0. The change law of the remaining bromine concentration in the wastewater was compared with image 3 . It can be seen from the results that, when the graphite electrode is used under the condition of PH=2.0, the Br ion in the water undergoes an electrolysis reaction, the concentration decreases rapidly, and then reaches the equilibrium concentration, and the removal rate of the Br ion can reach 65%, indicating that the lower the pH value, the more favorable Electrolytic recovery of Br ions. Graphite is used as the electrode. After long-term electrolysis expe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com