Zinc-plated hot-formed steel plate or steel strip with excellent cold bending performance and manufacturing method thereof

A technology of cold bending performance and manufacturing method, which is applied in the direction of hot-dip plating process, coating, metal material coating process, etc., can solve the problems of increasing the friction coefficient between steel plate and mold, restricting production and use, and reducing the service life of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

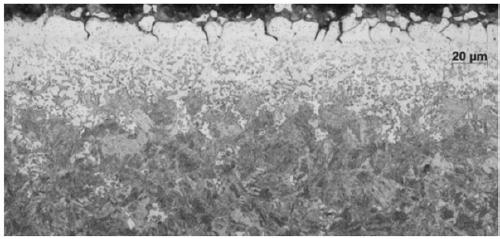

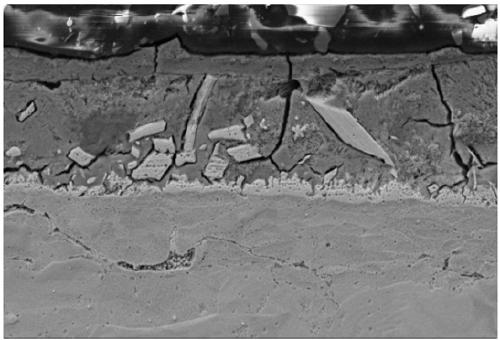

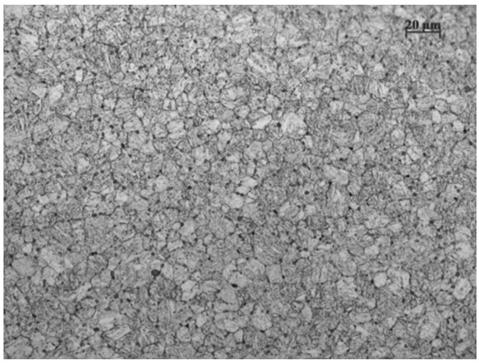

[0064] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0065] Examples of the present invention refer to Table 1 and Table 2.

[0066] Steel plates 1-6 having the chemical compositions shown in Table 1 were melted and cast. These steel plates are heated to 1230°C for controlled rolling, the final rolling temperature is 900°C, and then a hot-rolled steel plate with a thickness of about 3mm is obtained at a coiling temperature of 600°C, and the hot-rolled steel plate is pickled and then cold-rolled to a thickness of 1.4mm. hard Board.

[0067] According to the conditions 1-6 in Table 2, recrystallize and anneal the above-mentioned hard-rolled sheets and hot-dip galvanize to obtain galvanized steel sheets, and then keep these steel sheets at 930°C for 4 minutes, and then send them to China according to the forming process in Table 2 Molded to B-pillar parts.

[0068] As can be seen from the results of compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com