Intelligent vinegar solid-state brewing equipment

A solid-state brewing and equipment technology, applied in the field of vinegar spraying equipment and intelligent fermentation, can solve the problems of increasing the chance of contamination, low equipment utilization, dust overflow, etc., to reduce the volatilization of wine and acetic acid, and improve the quality of fermented products , the effect of improving the degree of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further illustrated below in conjunction with the accompanying drawings and specific examples, and these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

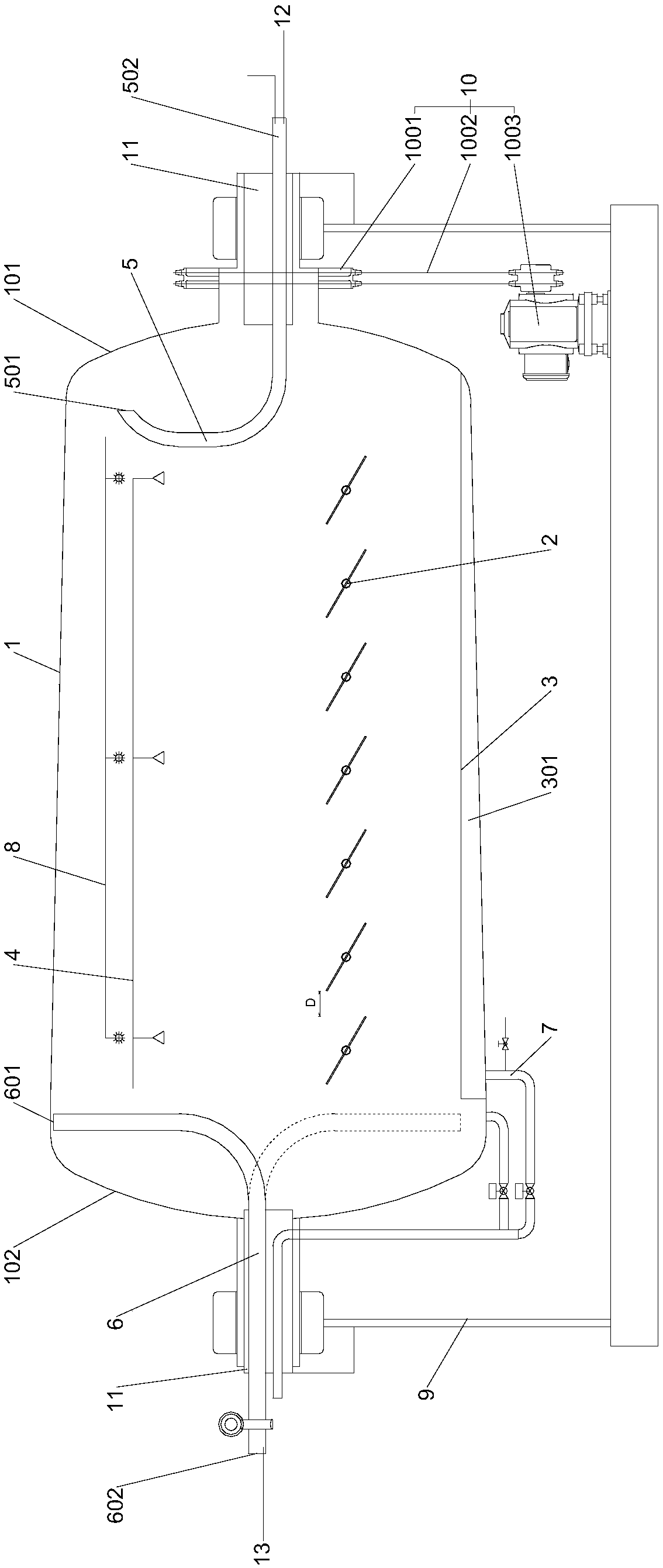

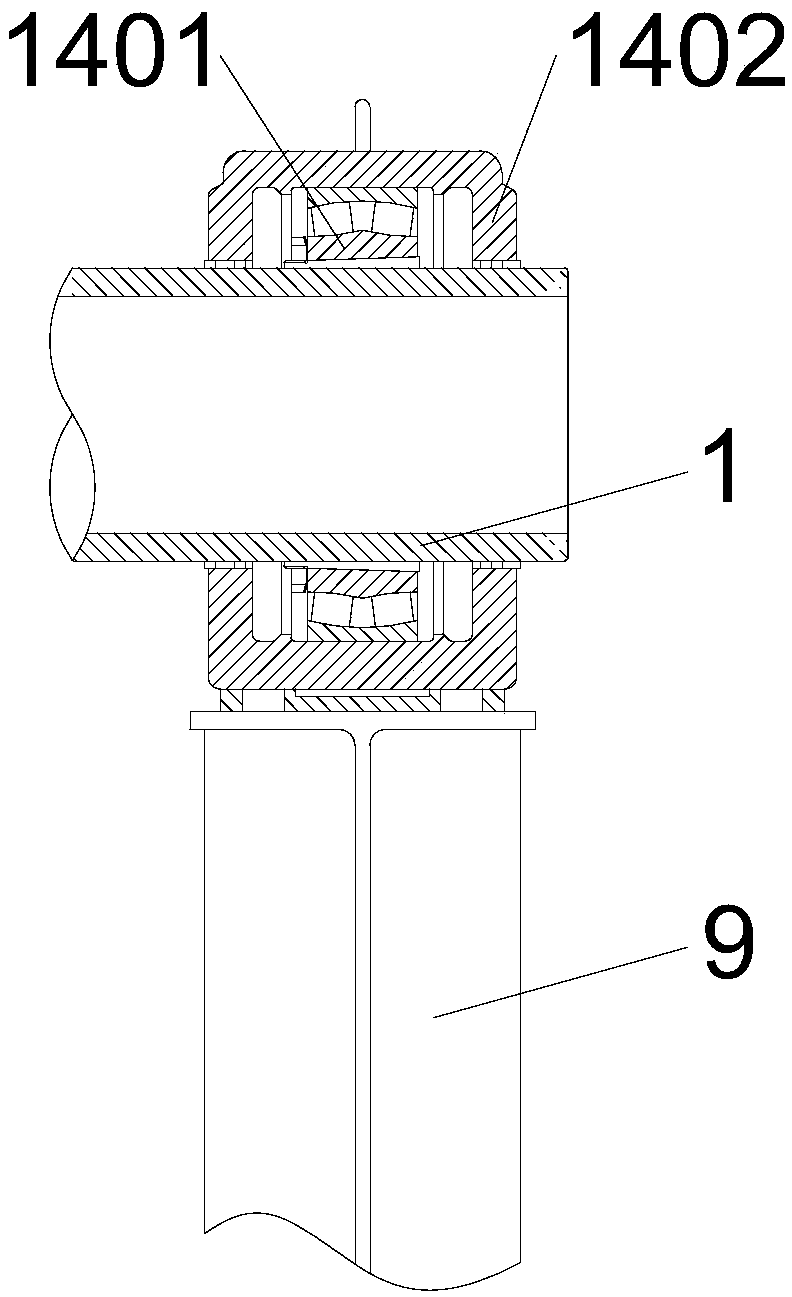

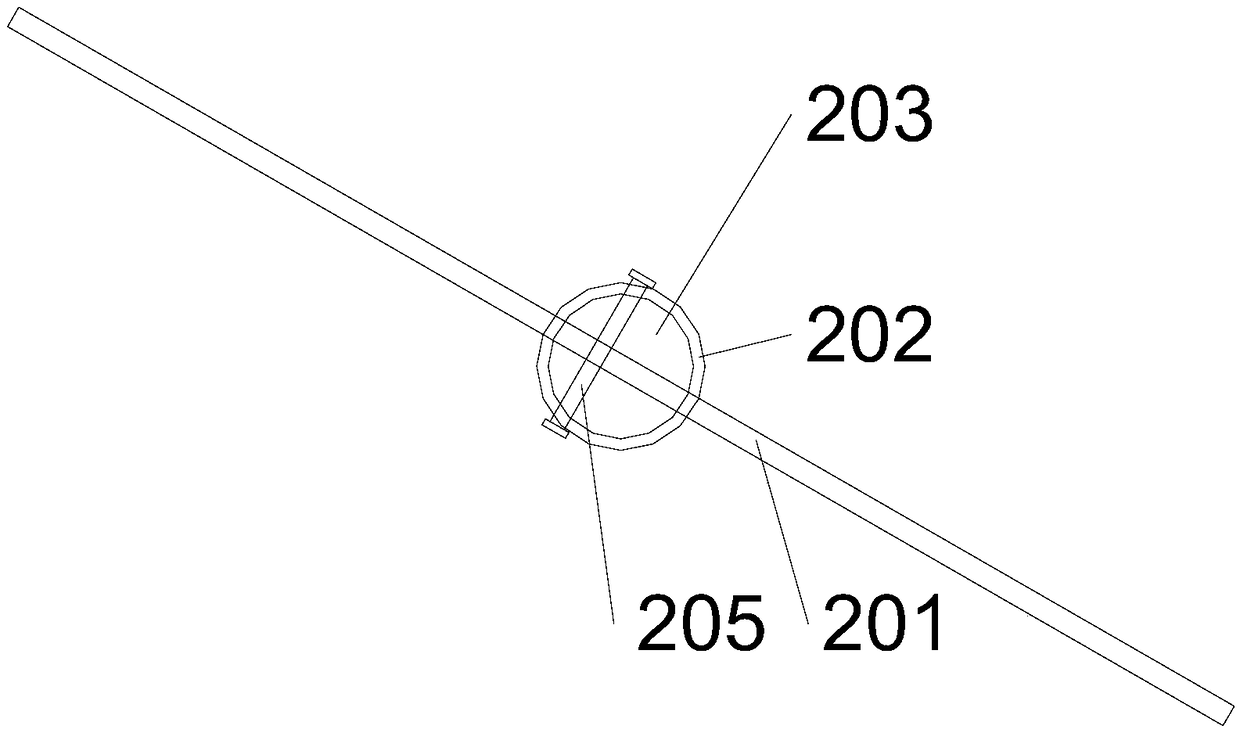

[0039] A kind of intelligent vinegar solid-state brewing equipment, as attached figure 1As shown, it mainly includes tank body 1, spiral turning mechanism 2, filter plate false bottom 3, spray device 4, feed pipe 5, discharge pipe 6, liquid discharge pipe 7, cleaning pipe 8, ventilation pipe, bracket 9 , driving device 10, positive pressure pneumatic conveying source 12, negative pressure pneumatic conveying source 13, spiral reverse deflector, PLC automatic control system, and temperature, oxygen concentration, alcohol content, acidity monitoring devices, etc. The PLC automatic control system controls the automatic operation of the entire equipment, and related operations include tank rotation start and stop, pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com