In-situ passivation repairing agent of cadmium-arsenic combined pollution farmland soil, preparation method and application

A technology of compound pollution and remediation agents, which is applied in the field of remediation of heavy metal pollution in farmland soil, to achieve the effect of improving nutrient status, simple modification and treatment methods, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Phosphate rock powder P used in the embodiment 2 o 5 % is 25%, the main composition of steel slag: CaO is 42.4%, SiO 2 33%, Al 2 o 3 12%, MgO 5.86%, Fe 2 o 3 0.57% for MnO, 0.39% for MnO, and 5.78% for others.

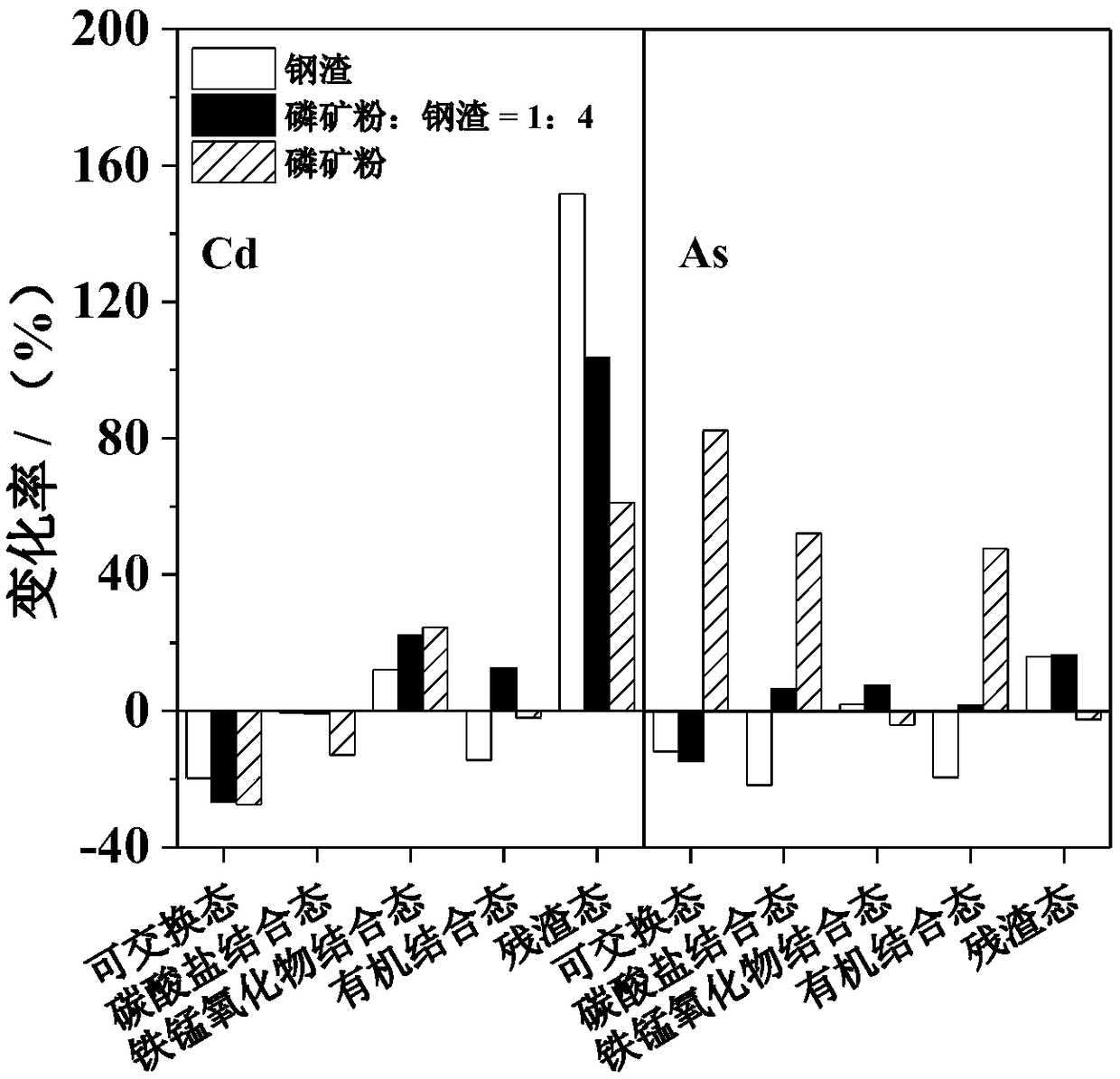

[0023] Grind the phosphate rock powder and steel slag separately, and pass through 400 mesh, and measure the particle size D of the phosphate rock powder 50 17.23μm, steel slag particle size D 50 It is 21.22μm, and according to powder mass: solution volume = 1:10, add 0.5mol / L oxalic acid solution. After stirring and mixing, stand at room temperature for 2 days, then dry at 60°C, and grind through a 100-mesh sieve. Mix the modified phosphate rock powder and steel slag in a mass ratio of 1:4 with a vibrating screen machine to obtain repair agent 1.

[0024] Mix the restoration agent 1 with 100g of the test soil evenly with 1% of the soil mass. Water was added every day to maintain the soil water content at 60% of the maximum water holding capacity in th...

Embodiment 2

[0027] Phosphate rock powder P used in the embodiment 2 o 5 % is 25%, the main composition of steel slag: CaO is 42.4%, SiO 2 33%, Al 2 o 3 12%, MgO 5.86%, Fe 2 o 3 0.57% for MnO, 0.39% for MnO, and 5.78% for others.

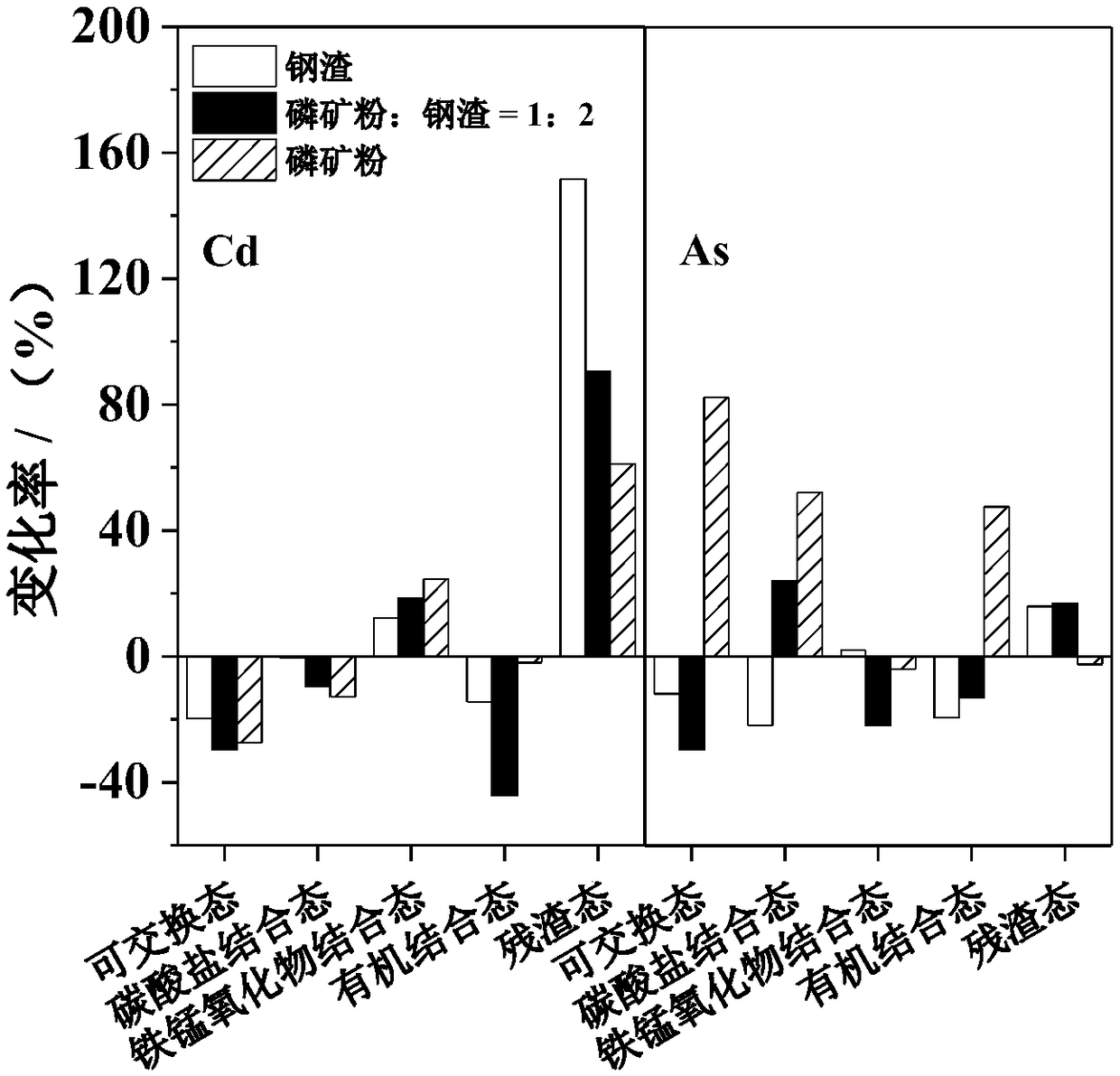

[0028] Grind the phosphate rock powder and steel slag separately, and pass through 400 mesh, and measure the particle size D of the phosphate rock powder 50 17.23μm, steel slag particle size D 50 21.22μm, and according to powder mass: solution volume = 1:10, add 0.5mol / L oxalic acid solution. After stirring and mixing, stand at room temperature for 2 days, then dry at 60°C, and grind through a 100-mesh sieve. Mix the modified phosphate rock powder and steel slag in a mass ratio of 1:2 with a vibrating screen machine to obtain repair agent 2.

[0029] Mix the restoration agent 2 with 100g of the test soil evenly with 1% of the soil mass. Water was added every day to maintain the soil water content at 60% of the maximum water holding capacity in the fiel...

Embodiment 3

[0032] Phosphate rock powder P used in the embodiment 2 o 5 % is 25%, the main composition of steel slag: CaO is 42.4%, SiO 2 33%, Al 2 o 3 12%, MgO 5.86%, Fe 2 o 3 0.57% for MnO, 0.39% for MnO, and 5.78% for others.

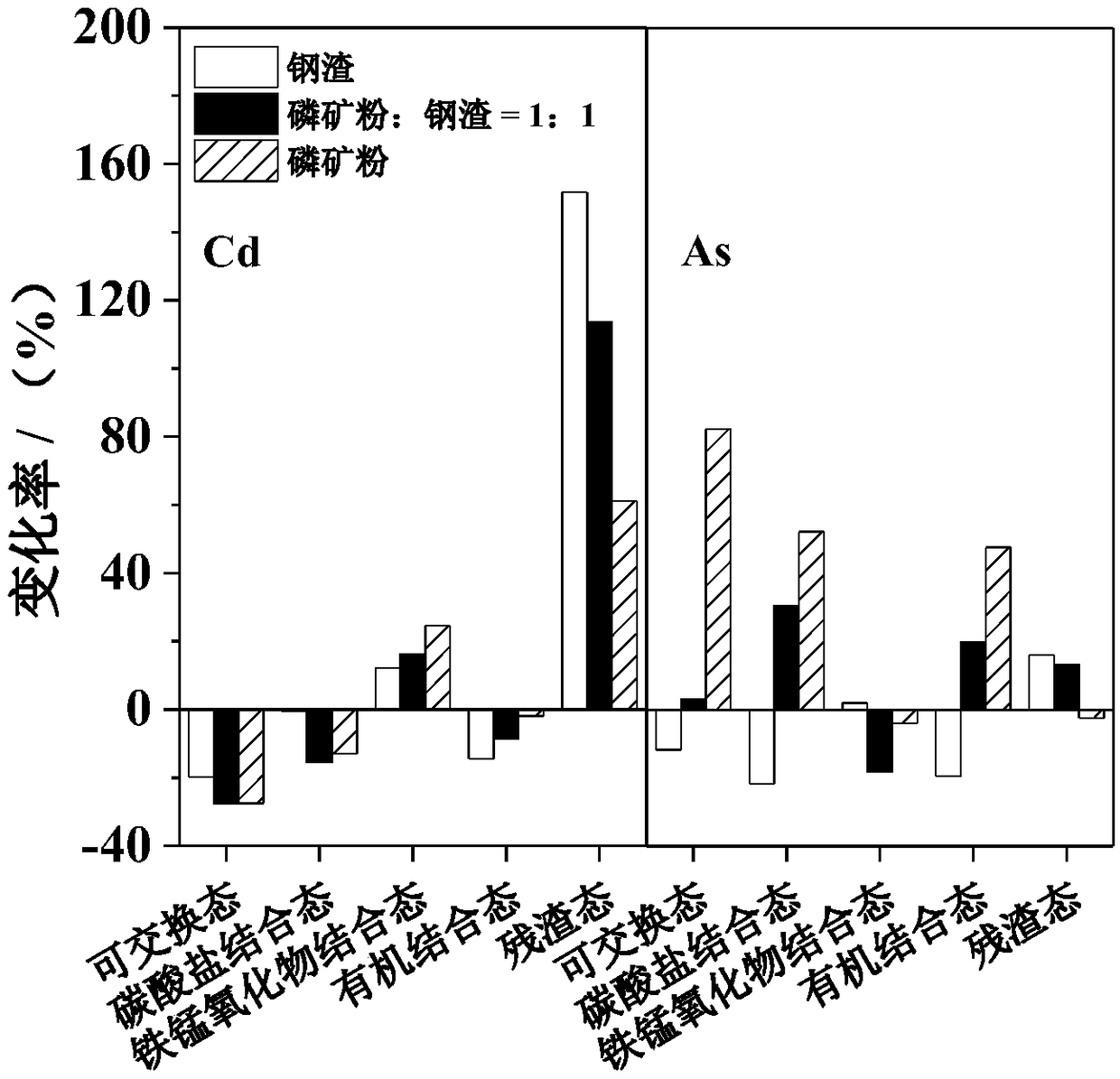

[0033] Grind the phosphate rock powder and steel slag separately, and pass through 400 mesh, and measure the particle size D of the phosphate rock powder 50 17.23μm, steel slag particle size D 50 21.22μm, and according to powder mass: solution volume = 1:10, add 0.5mol / L oxalic acid solution. After stirring and mixing, stand at room temperature for 2 days, then dry at 60°C, and grind through a 100-mesh sieve. Mix the modified phosphate rock powder and steel slag in a mass ratio of 1:1 with a vibrating screen machine to obtain repair agent 3.

[0034] Mix the restoration agent 3 with 100g of the test soil evenly with 1% of the soil mass. Water was added every day to maintain the soil water content at 60% of the maximum water holding capacity in the fiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com