A kind of refining method of capsicum red pigment slag

A technology of capsanthin and a refining method, which is applied to the refining of plant extracts and the refining of capsanthin residues, can solve the problems of affecting product quality, incomplete separation, long saponification time, etc., and achieves reduced product viscosity and fluidity. Good, simple method of refining the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method comprises the following steps:

[0029] A. Add ester solvent in capsanthin slag, heat, stir, obtain capsanthin slag dissolving solution;

[0030] Capsanthin slag is any of the scum-like pigments produced during the production of capsanthin, the precipitated residue formed during the storage of capsanthin, or the centrifuged slag produced after centrifugation of capsanthin;

[0031] The ester solvent is any one of ethyl acetate, butyl acetate or isopropyl acetate, the ratio of the mass of capsicum red pigment slag in grams to the volume of the ester solvent in milliliters is 1:3-6, and the heating temperature is 40-40 60°C;

[0032] B. The solution of capsanthin slag is frozen at -15~-5℃ for 8~12h, then centrifuged at -15~-5℃ to obtain the filter residue and supernatant of capsanthin slag until the capsanthin slag The supernatant is clear and transparent, and there is no floc and precipitation when placed at -15~-5℃ for 30~60 minutes;

[0033] C...

Embodiment 1

[0038] A method for refining capsanthin slag, comprising freezing and weak alkaline water treatment.

[0039] The preparation method comprises the following steps:

[0040] A. Add 300 mL of ethyl acetate to 100 g of dregs-like pigment produced during the production of capsanthin with a color value of E120, heat to 60° C., stir well, and obtain a solution of capsanthin dregs;

[0041] B. Pass chilled water through the capsicum red pigment slag solution, cool down to -5°C, and freeze at -5°C for 8 hours. Centrifuge at -15°C to obtain filter residue and capsanthin residue supernatant. The capsanthin slag supernatant was placed at -5°C for 30 minutes without floc and precipitation;

[0042] C. Add 90mL of a mixed solution of sodium hydroxide solution and sodium carbonate solution to 270mL capsanthin slag supernatant, wherein the mass fraction of sodium hydroxide solution is 0.1%, the mass fraction of sodium carbonate solution is 3%, and sodium hydroxide The volume ratio of the ...

Embodiment 2~3

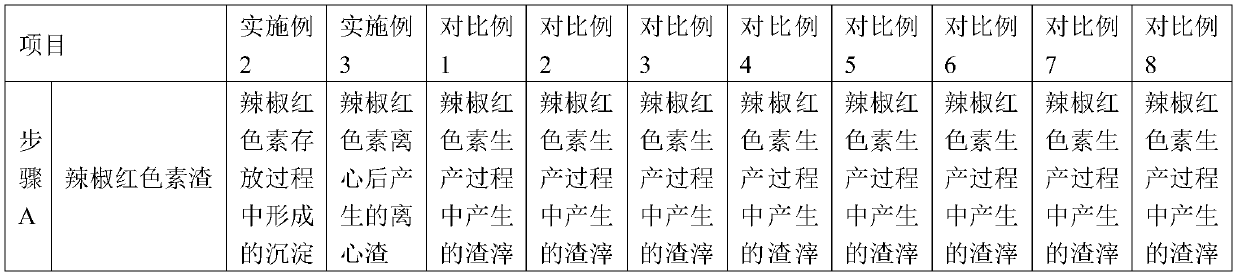

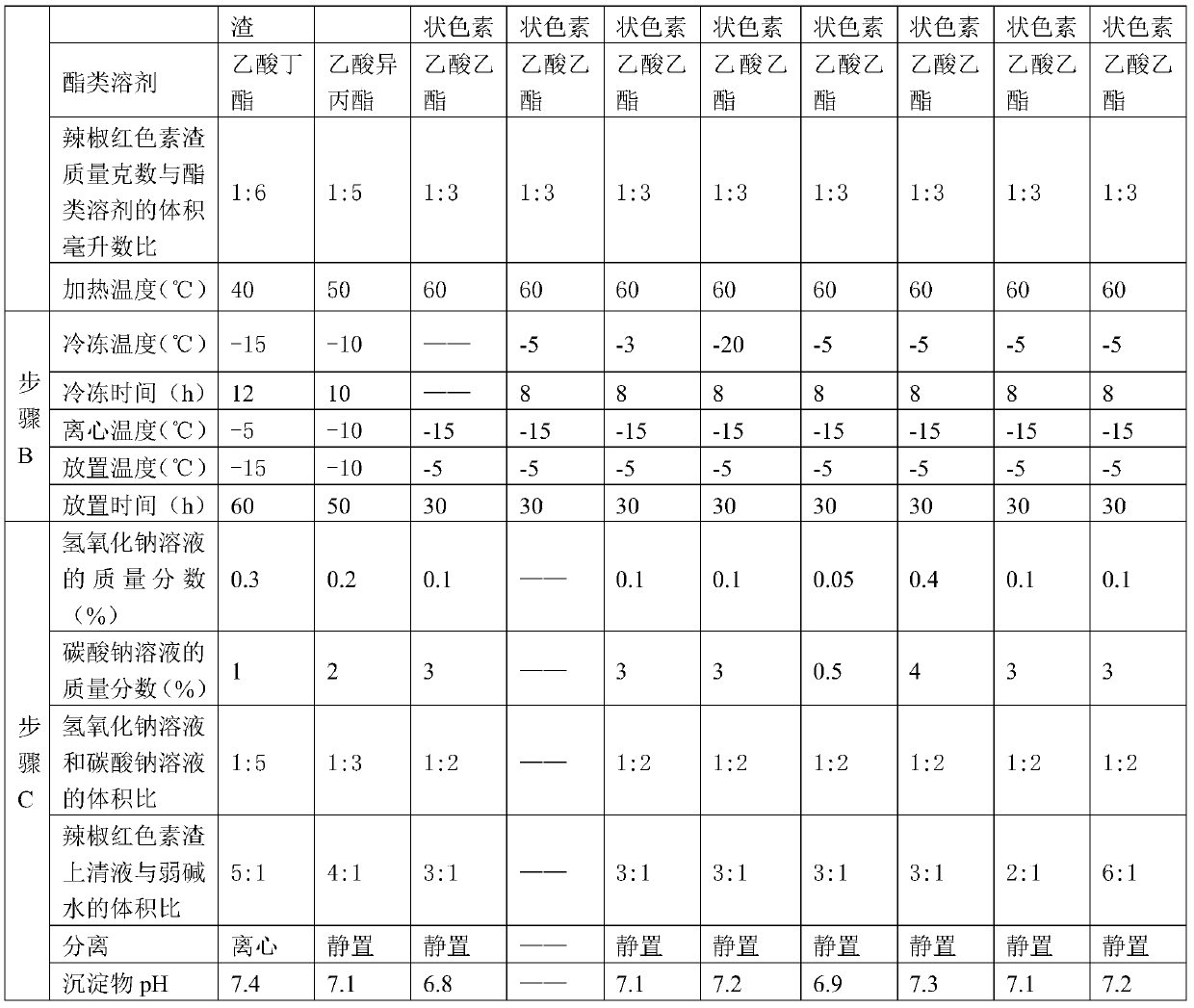

[0046] Embodiments 2-3 have the same production process steps as Embodiment 1, the difference is the selection of process parameters, as shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com