Sheet metal part machining device

A processing device and technology for sheet metal parts, applied in the field of sheet metal parts processing, can solve the problems of low punching quality of sheet metal parts, achieve the effects of shortening the processing cycle, reducing the probability of burrs, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

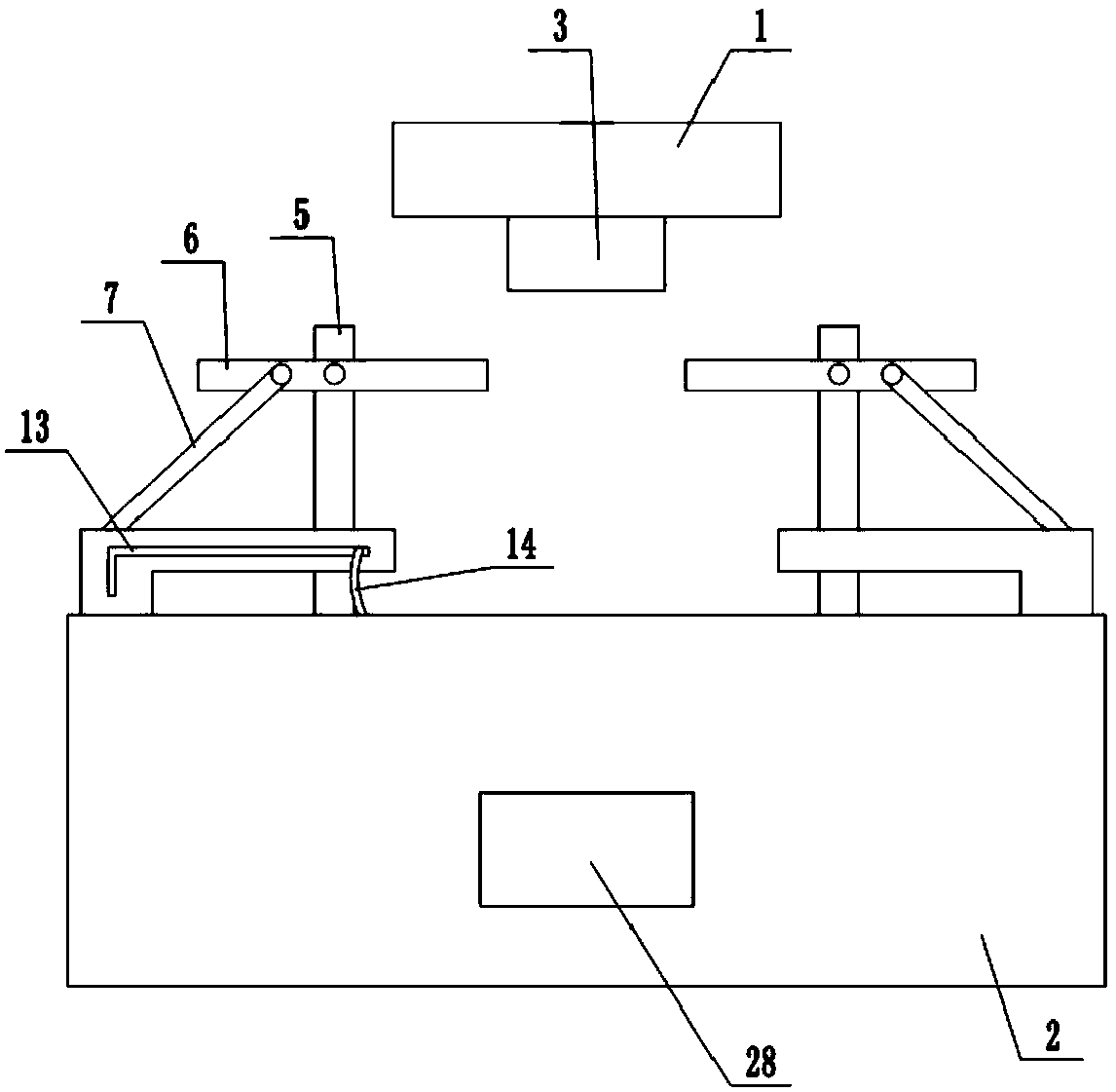

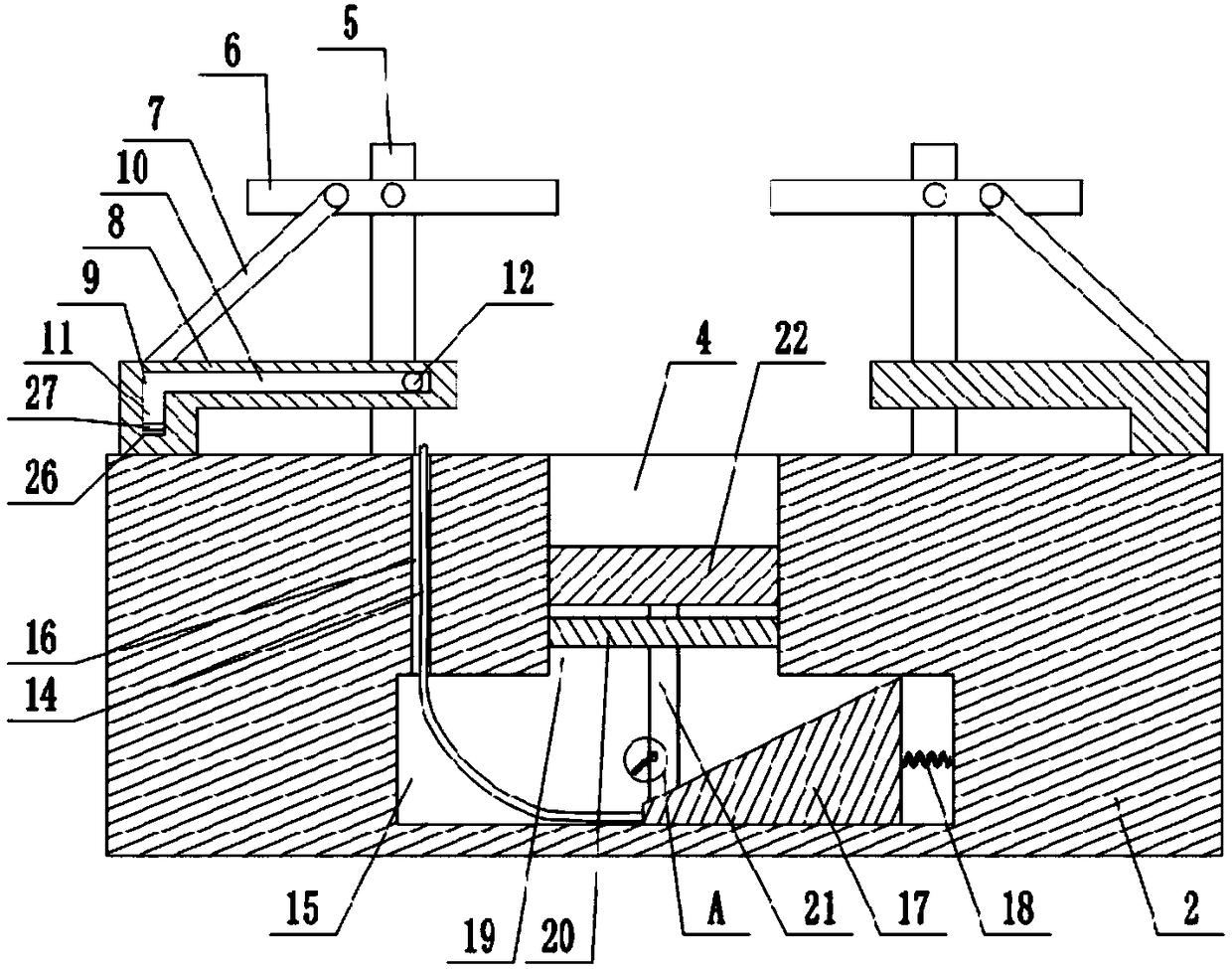

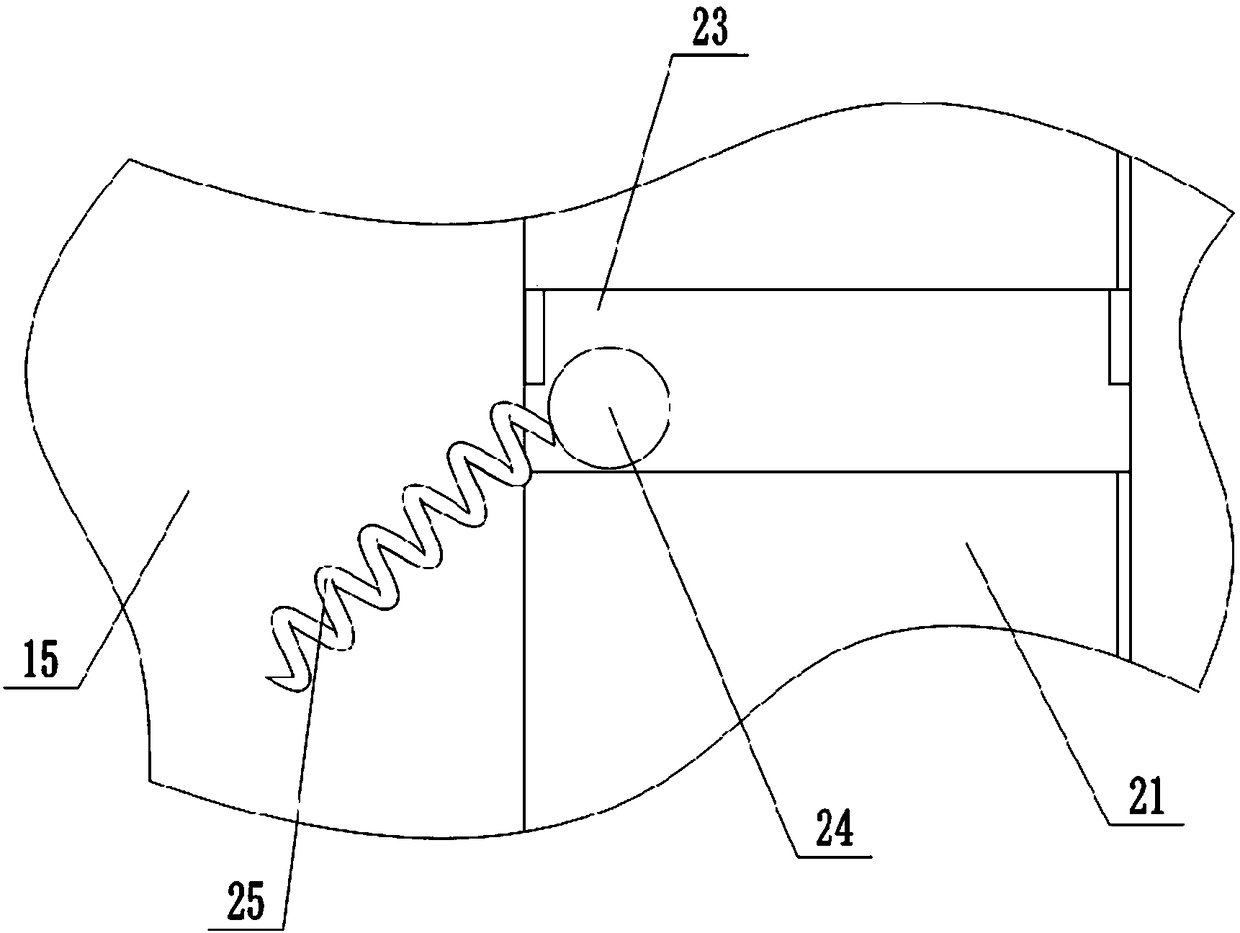

[0032] The following is further described in detail through specific implementation methods:

[0033] The reference signs in the drawings of the description include: upper mold 1, lower mold 2, convex part 3, concave part 4, cylinder 5, rotating rod 6, connecting rod 7, slide plate 8, chute 9, horizontal part 10, vertical part Part 11, slider 12, sliding hole 13, pull cord 14, movable cavity 15, vertical hole 16, moving plate 17, first elastic member 18, through hole 19, fixed plate 20, screw rod 21, grinding block 22, annular groove 23. Rotating bead 24, second elastic member 25, electromagnet 26, magnetic block 27, discharge port 28.

[0034] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0035] The sheet metal parts processing device is mainly composed of an upper mold 1, a lower mold 2, a convex part 3, a concave part 4, a pressing mechanism, a grinding mechanism, and a pulling mechanism. The lower mold 2 is installed on the frame, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com