Filter cloth with antibacterial function and preparation method of filter cloth

A technology of filter cloth and function, which is applied in the field of filter cloth with antibacterial function and its preparation, which can solve the problems that the filter material does not have antibacterial function, and achieve the effects of reducing antibacterial performance, improving antibacterial performance, and improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

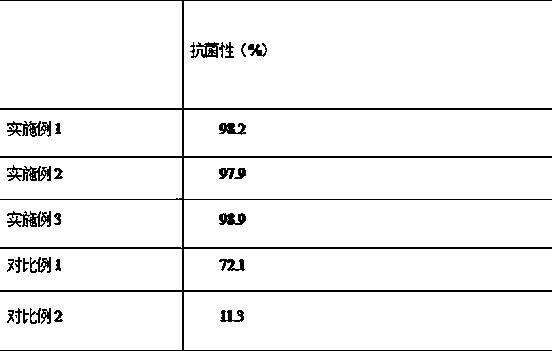

Examples

Embodiment 1

[0023] A kind of filter cloth with antibacterial function of the present embodiment, comprises the raw material of following weight portion:

[0024] 30 parts of glass fiber, 15 parts of modified banana fiber, 10 parts of silver fiber, 6 parts of graphene, 8 parts of modified diatomaceous earth, 5 parts of modified vegetable oil, 6 parts of nano silicon powder, 3 parts of sodium palmitate, rare earth chlorine 2 parts of lanthanum chloride, 20 parts of deionized water.

[0025] The preparation method of the modified banana fiber of this embodiment is to place the banana fiber in a Soxhlet extractor, wash the banana fiber with acetone solution for 24 hours, then take out the washed banana fiber, put it in a vacuum drying oven and dry it until Constant weight, then soak the fiber with 3% mass fraction of silane coupling agent KH550 and γ-aminopropylmethyldimethoxysilane to reflux respectively, the heating temperature is 95°C, the reflux time is 2h, and then take it out and dry it...

Embodiment 2

[0033] A kind of filter cloth with antibacterial function of the present embodiment, comprises the raw material of following weight portion:

[0034] 40 parts of glass fiber, 25 parts of modified banana fiber, 20 parts of silver fiber, 10 parts of graphene, 14 parts of modified diatomaceous earth, 11 parts of modified vegetable oil, 12 parts of nano silicon powder, 5 parts of sodium palmitate, rare earth chlorine 5 parts of lanthanum chloride, 30 parts of deionized water.

[0035] The preparation method of the modified banana fiber of this embodiment is to place the banana fiber in a Soxhlet extractor, wash the banana fiber with acetone solution for 28 hours, then take out the washed banana fiber, put it into a vacuum drying oven and dry it until Constant weight, then soak the fiber with 3% mass fraction of silane coupling agent KH550 and γ-aminopropylmethyldimethoxysilane to reflux respectively, the heating temperature is 105°C, the reflux time is 2h, and then take it out and...

Embodiment 3

[0043] A kind of filter cloth with antibacterial function of the present embodiment, comprises the raw material of following weight portion:

[0044] 35 parts of glass fiber, 20 parts of modified banana fiber, 15 parts of silver fiber, 8 parts of graphene, 11 parts of modified diatomaceous earth, 9 parts of modified vegetable oil, 9 parts of nano silicon powder, 4 parts of sodium palmitate, rare earth chlorine 3.5 parts of lanthanum chloride, 25 parts of deionized water.

[0045] The preparation method of the modified banana fiber of this embodiment is to place the banana fiber in a Soxhlet extractor, wash the banana fiber with acetone solution for 26 hours, then take out the washed banana fiber, put it in a vacuum drying oven and dry it until Constant weight, then soak the fiber with 3% mass fraction of silane coupling agent KH550 and γ-aminopropylmethyldimethoxysilane to reflux respectively, the heating temperature is 100°C, the reflux time is 2h, and then take it out and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com