A method of using kitchen waste and sludge to produce combustible gas

A kitchen waste and sludge technology, which is applied in sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problem of low combustible gas production rate, achieve stable gas output, slow down pH drop, and fast speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

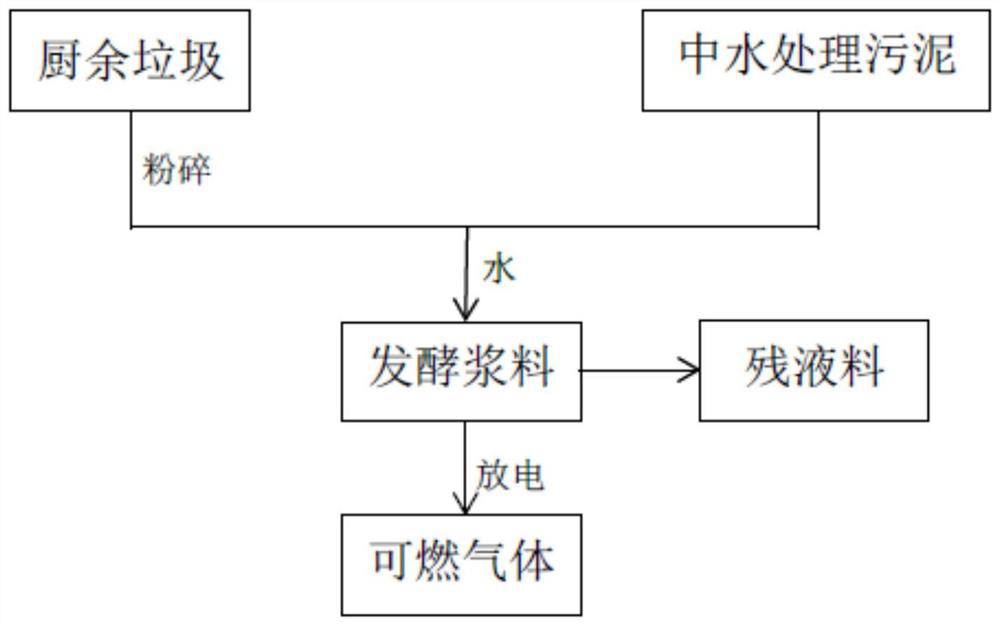

[0029] Example 1 Production of combustible gas

[0030] A custom-made 50L jacketed reactor is used. There are 5 pairs of electrode rods evenly arranged in an array at the bottom of the reactor. The positive pole is carbon rods, and the negative pole is stainless steel. . The pressure in the tank is greater than 0.20MPa, and the gas is released automatically.

[0031] (1) The kitchen waste containing green plants is pre-crushed into 10 meshes, and then mixed with reclaimed water treatment sludge with a water content of 80% in a mass ratio of 3:1 to form a fermented slurry with a solid content of 8%;

[0032] (2) After the negative pressure of the vacuum fermentation tank is pumped to -0.05MPa, the fermentation slurry is pumped in so that the fermentation slurry does not pass through the electrodes; the discharge treatment is carried out in the first 3 days after feeding, and the discharge is performed when the pressure in the tank is lower than 0.25MPa. Stop discharging when ...

Embodiment 2

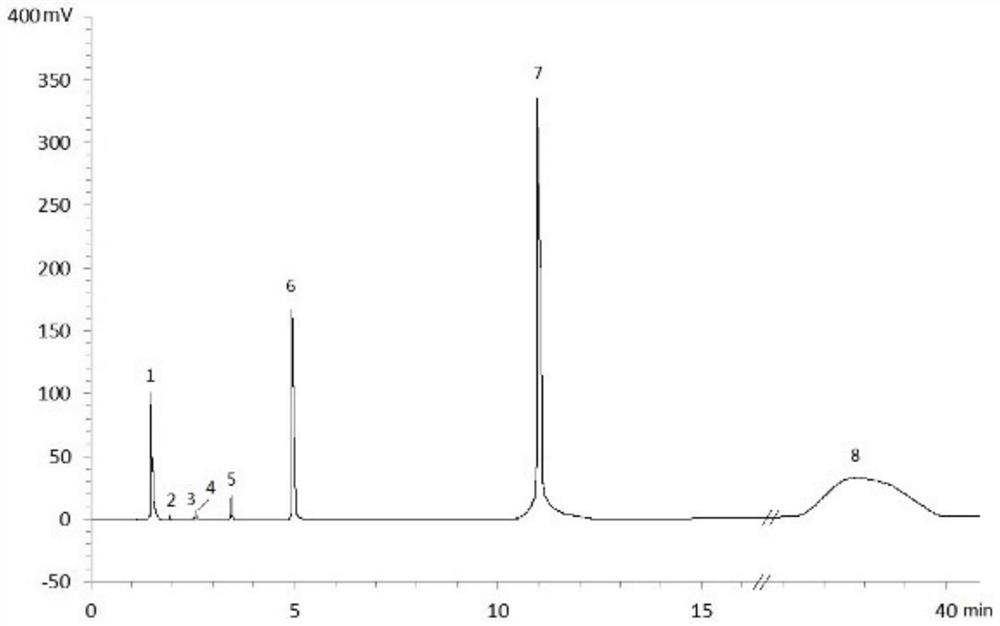

[0053] Example 2 Gas composition detection

[0054] The combustible gas obtained on the 4th day in each embodiment and comparative example was dried by Shimadzu GC-7A gas chromatograph, and then the components were detected. Dry gas chromatographic conditions before detection are as follows:

[0055] Column temperature: 70°C;

[0056] Inlet temperature: 95°C;

[0057] Thermal conductivity detector (TCD) temperature: 80°C;

[0058] Carrier gas: high-purity argon;

[0059] Flow: 30mL / min;

[0060] Chromatographic column: stainless steel column filled with carbon molecular sieve, 3m×3mm;

[0061] Injection volume: 1000 μL;

[0062] The gas analysis spectrum of embodiment 1 is as figure 2 shown. The contents of different components in each gas were calculated, and the results are shown in Table 1.

[0063] Table 1 Comparison of gas composition and content in different gas samples

[0064]

[0065] It can be seen from the data in Table 1 that among the gas samples, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com