LED-UV jet ink and preparation method thereof

An inkjet ink and monomer technology, applied in the field of LED-UV inkjet ink and its preparation, can solve the problems of oblique jetting of ink droplets, poor stability and adhesion of LED-UV inkjet ink, clogging of nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

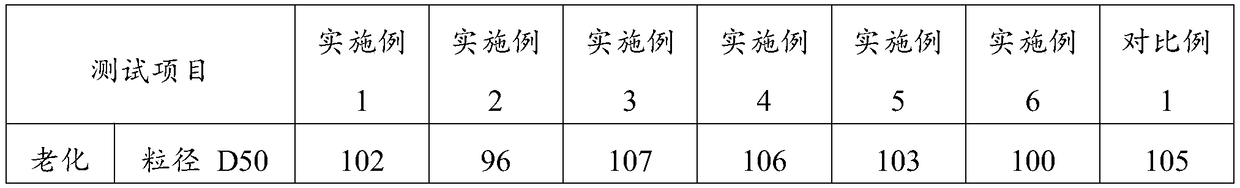

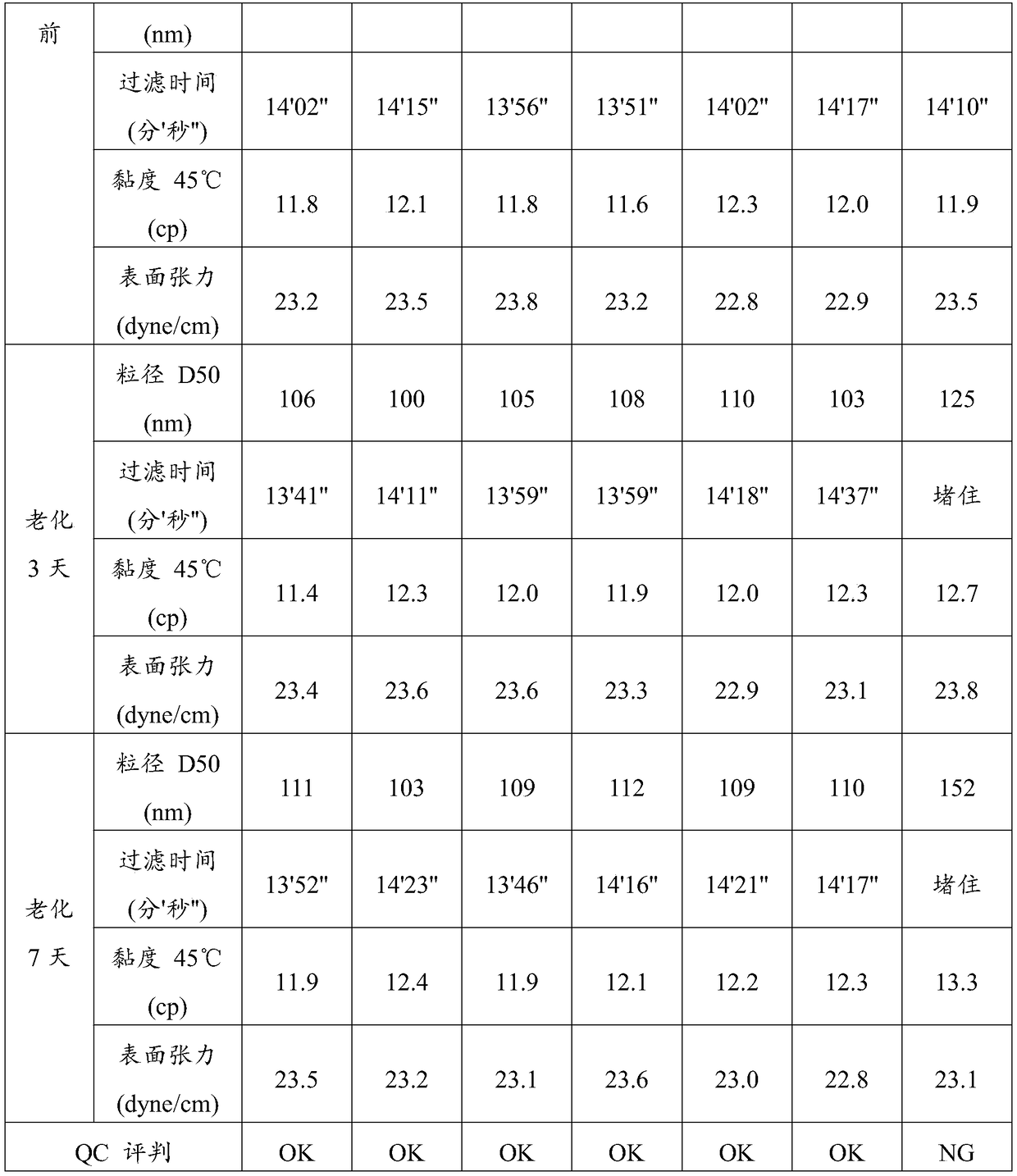

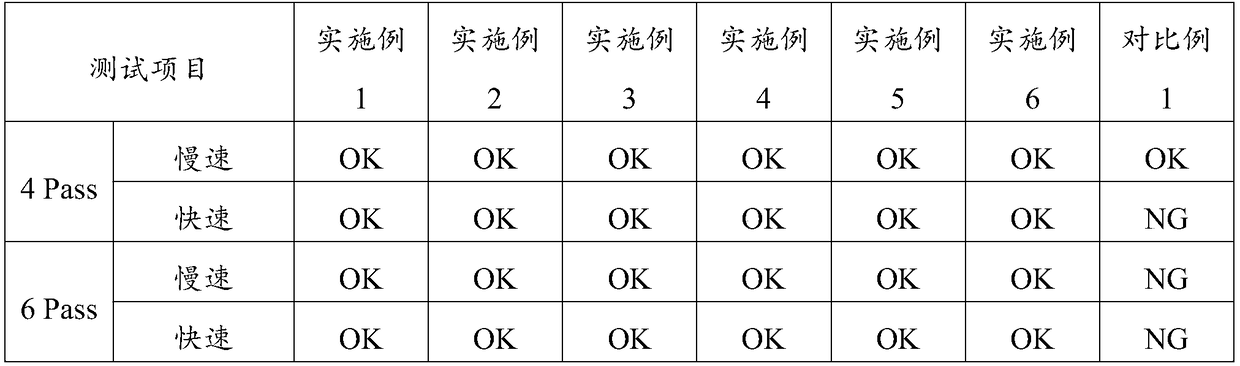

Examples

preparation example Construction

[0047] The present invention also provides a preparation method of the LED-UV inkjet ink described in the above technical solution, comprising the following steps:

[0048] (1) Dissolving the photoinitiator by monomer to obtain a pre-solution;

[0049] (2) Stir and mix the resin and the color paste with the pre-solution obtained in the step (1) to obtain the LED-UV inkjet ink.

[0050] The invention adopts the monomer to dissolve the photoinitiator to obtain the pre-solution.

[0051] In the present invention, there is no particular limitation on the specific implementation of the monomer-dissolving photoinitiator, and a method well known to those skilled in the art can be used.

[0052] After the pre-solution is obtained, the present invention stirs and mixes the resin and the color paste with the pre-solution to obtain the LED-UV inkjet ink.

[0053] In the present invention, the rotational speed of the stirring and mixing is preferably 500-1500 rpm, more preferably 800-13...

Embodiment 1

[0060] The LED-UV inkjet ink is composed of: 53.5 parts of tetrahydrofurfuryl acrylate, 4.0 parts of tri(ethoxy)trimethylolpropane triacrylate, 4.0 parts of polyester acrylic oligomer, chlorine 2.6 parts of acetic resin, 7.0 parts of 2,4,6-trimethylbenzoyldiphenylphosphine oxide, 3 parts of 2,4-diethylthiazolone, 0.2 parts of BYK-378 wetting agent, GENORAD16 stabilizer 0.7 parts, 25 parts of red color paste. The red color paste contains 20.5 parts of 1,6-hexanediol diacrylate, 1.5 parts of Solsperse24000 dispersant, and 3 parts of PR122 pigment.

[0061] The preparation method of LED-UV inkjet ink is: using tetrahydrofurfuryl acrylate and tri(ethoxy)trimethylolpropane triacrylate to oxidize 2,4,6-trimethylbenzoyl diphenyl Phosphine and 2,4-diethylthiazolone are dissolved to obtain a pre-solution;

[0062] Stir and mix the pre-solution, polyester acrylic oligomer, vinyl acetate, BYK-378 wetting agent, GENORAD16 stabilizer and red color paste at a stirring speed of 1000rpm, an...

Embodiment 2

[0064] The LED-UV inkjet ink consists of 51.6 parts of tetrahydrofurfuryl acrylate, 5.0 parts of tri(ethoxy)trimethylolpropane triacrylate, 5.0 parts of polyester acrylic oligomer, chlorine 2.5 parts of acetic resin, 7.0 parts of 2,4,6-trimethylbenzoyldiphenylphosphine oxide, 3 parts of 2,4-diethylthiazolone, 0.2 parts of BYK-378 wetting agent, GENORAD16 stabilizer 0.7 parts, 25 parts of blue color paste. The blue color paste contains 20.5 parts of 1,6-hexanediol diacrylate, 1.5 parts of Solsperse 24000 dispersant, 0.5 parts of Solsperse 5000 additive, and 2.5 parts of PB15:3 pigment.

[0065] The preparation method of LED-UV inkjet ink is: using tetrahydrofurfuryl acrylate and tri(ethoxy)trimethylolpropane triacrylate to oxidize 2,4,6-trimethylbenzoyl diphenyl Phosphine and 2,4-diethylthiazolone are dissolved to obtain a pre-solution;

[0066] Stir and mix the pre-solution, polyester acrylic oligomer, vinyl acetate, BYK-378 wetting agent, GENORAD16 stabilizer and blue color...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com