Method for recovering lithium from lithium by-product sodium sulfate extracted from spodumene sulfuric acid process

A technology for extracting lithium and by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

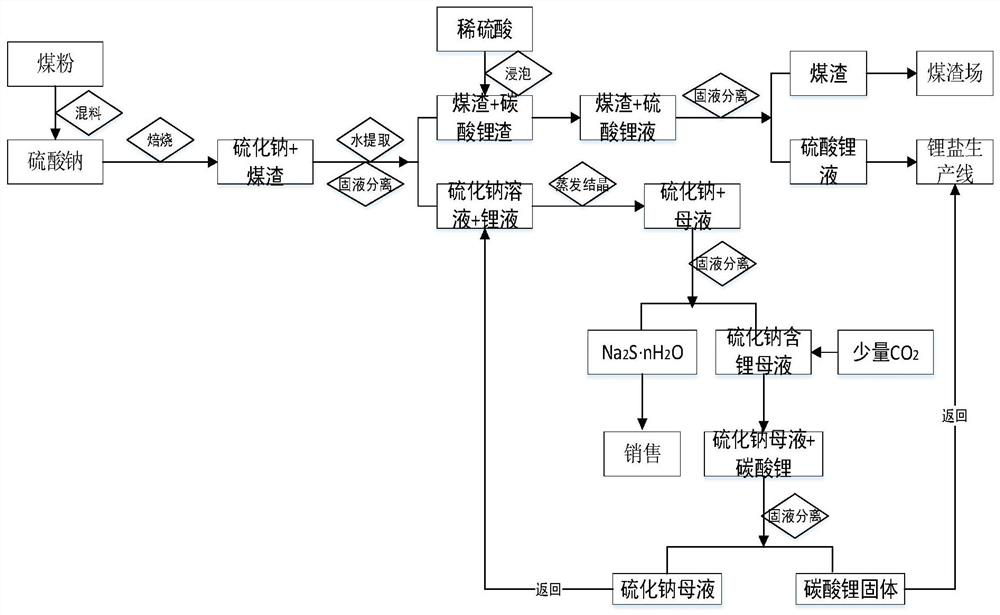

Image

Examples

Embodiment 1

[0039] Embodiment 1: the method for reclaiming lithium from lithium by-product sodium sulfate from spodumene sulfuric acid process

[0040] Include the following steps in order:

[0041] Step (1), get the sodium sulfate of lithium carbonate workshop, its main composition is as follows: (%)

[0042] Na 2 SO 4

Li 2 SO 4 (with Li 2 O meter)

Fe pH (5% aqueous solution) 99.35 0.035 0.0008 6.5

[0043] Take 2.1Kg of dry coal powder and 10Kg of sodium sulfate, mix them evenly, and react in an oxygen-isolated reactor at 825°C for 55 minutes. After the reaction is completed, cool to obtain a roasted material.

[0044] Step (2), the roasted material is extracted with hot water at 70°C, filtered and separated to obtain filter residue, filtrate and washing water, and the washing water is used for the next extraction;

[0045] In step (3), dilute sulfuric acid is added to the filter residue according to the alkali content to obtain lithium sulfate s...

Embodiment 2

[0050] Embodiment 2: the method for reclaiming lithium from lithium by-product sodium sulfate from spodumene sulfuric acid process

[0051] Include the following steps in order:

[0052] Step (1), get the sodium sulfate of lithium hydroxide workshop, its main composition is as follows: (%)

[0053] Na 2 SO 4

Li 2 SO 4 (with Li 2 O meter)

Fe pH (5% aqueous solution) 98.77 0.27 0.0007 12

[0054] Take 2.9Kg of dry coal powder and 10Kg of sodium sulfate, mix them evenly, and react in an oxygen-isolated reactor at 1075°C for 25 minutes. After the reaction is completed, cool to obtain a roasted material.

[0055] Step (2), the roasted material is extracted with hot water at 40°C, filtered and separated to obtain filter residue, filtrate and washing water, and the washing water is used for the next extraction;

[0056] In step (3), dilute sulfuric acid is added to the filter residue according to the alkali content to obtain lithium sulfate ...

Embodiment 3

[0061] Embodiment 3: the method for reclaiming lithium from lithium by-product sodium sulfate from spodumene sulfuric acid process

[0062] Include the following steps in order:

[0063] Step (1), get the sodium sulfate of lithium carbonate workshop, its main composition is as follows: (%)

[0064] Na 2 SO 4

Li 2 SO 4 (with Li 2 O meter)

Fe pH (5% aqueous solution) 99.22 0.15 0.0006 5.8

[0065] Take 2.5Kg of dry coal powder and 10Kg of sodium sulfate, mix them evenly, and react in an oxygen-isolated reactor at 895°C for 40 minutes. After the reaction is completed, cool to obtain a roasted material.

[0066] Step (2), the roasted material is extracted with hot water at 40°C, filtered and separated to obtain filter residue, filtrate and washing water, and the washing water is used for the next extraction;

[0067] In step (3), dilute sulfuric acid is added to the filter residue according to the alkali content to obtain lithium sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com