Fuel cell stack

A fuel cell stack and battery technology, which is applied to fuel cells, fuel cell groups, circuits, etc., can solve problems such as uneven distribution of preload force, damage to the gas diffusion layer structure, and influence on the life of the stack, and simplify the production process. process, avoid irreversible damage, and apply uniformly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

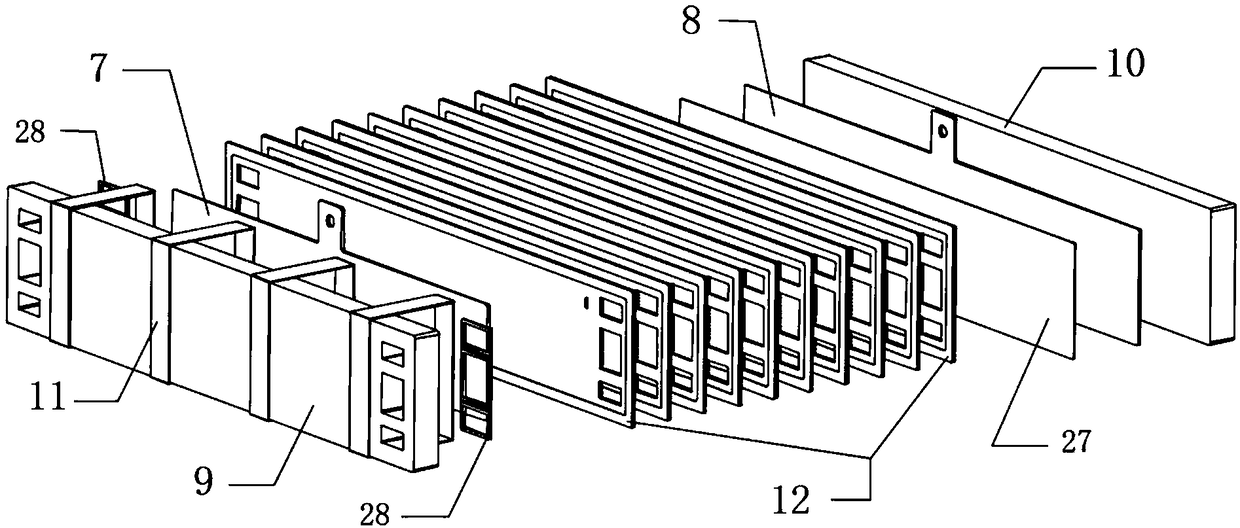

[0045] This example assembles one by 200 single cells 12, and the active area of single cells 12 is 250cm 2 the stack.

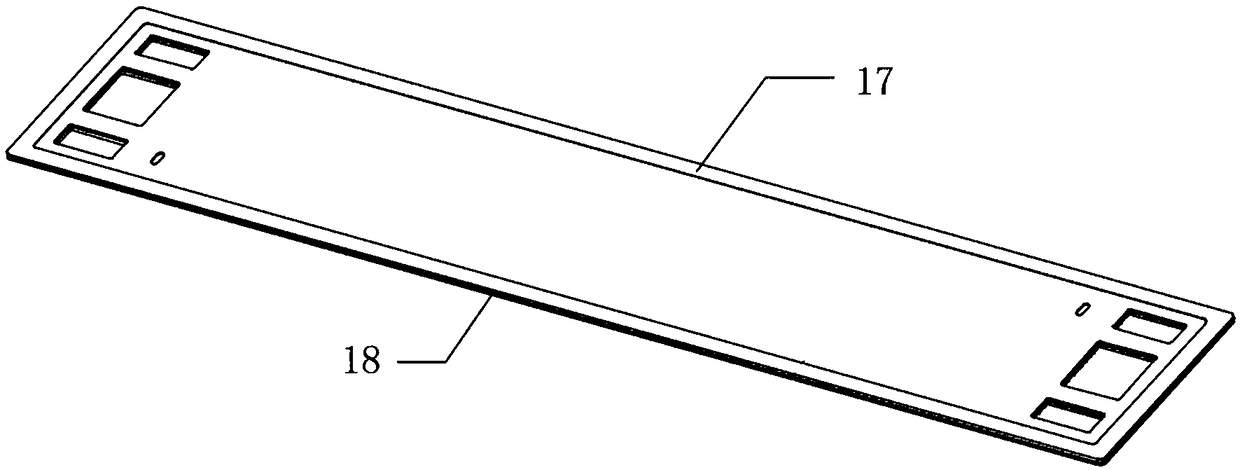

[0046] Such as figure 1 with figure 2 As shown, the fuel cell stack includes a battery pack formed by stacking a plurality of single cells 12. The upper and lower ends of the battery pack are respectively provided with a front end plate 9 and a rear end plate 10. The upper end of the battery pack is connected to the front end plate 9. A front-end current collecting plate 7 is provided between them, and a rear-end current collecting plate 8 is provided between the lower end of the battery pack and the rear end plate 10; the battery pack, the front end plate 9 and the rear end plate 10 are fixed as a whole by a strap 11, The material of the strapping straps 11 is stainless steel or titanium, the number of the strapping straps 11 is 3-8, the strapping straps 11 are non-intersecting, and the gap between the rear collector plate 8 and the battery pack is A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com