Full-spectrum white LED device

A LED device, full-spectrum technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of immature coating technology of white reflective glue, inability to effectively cover the silver plating layer, and inability to guarantee product reliability. Good uniformity, good use effect, and effect of improving tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The device packaging process is as follows:

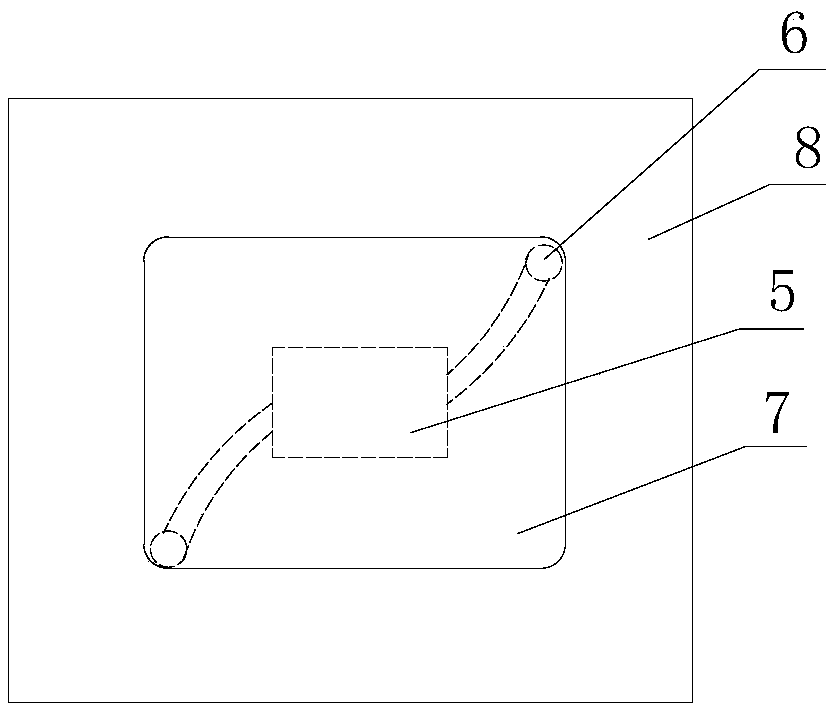

[0039] 1. Die-bonding: use common die-bonding glue to fix the LED chip on the dispensing area 1 of the bracket 8 , and in this embodiment, select the near-ultraviolet LED chip 5 with a luminous peak wavelength at 405nm.

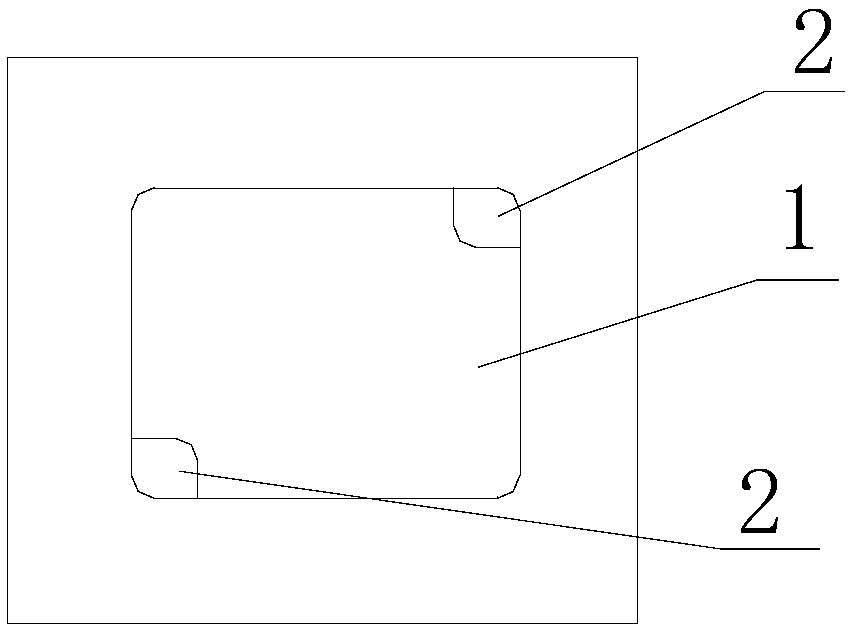

[0040] 2. Spot welding: connect the positive and negative poles of the LED chip 5 to the positive and negative poles 2 on the front side of the bracket respectively through gold wires, and spot welding forms a path, and the solder joints 6 completely cover the positive and negative poles 2 .

[0041] 3. Glue dispensing: mix the mixed colloid containing red, green and blue fluorescent powder 7 according to a certain proportion, stir evenly, and put it on the chip in dispensing area 1 after vacuum defoaming.

[0042] The composition formula of red phosphor is: CaAlSi(ON )3 : Eu, the peak wavelength of the emission spectrum is 620-650nm, and the half-maximum width is 105-135nm;

[0043] The composition formu...

Embodiment 2

[0050] With the technology of embodiment 1, adjust phosphor proportion, use support of the present invention and general commercially available alumina ceramic support (silver-plated layer is filled with luminous area) to pack into warm white 3200K full-spectrum LED device, and emission spectrum is as follows: Figure 8 shown. The light efficacy of both is 80lm / W.

[0051] Both were lighted and aged in an aging box, and the aging conditions were the same as in Example 1. Such as Figure 9 Compared with the aging characteristics shown, the present invention adopts the hidden silver plating layer design, and the reliability of the packaged device is good. According to the test results, the service life is close to 50000h.

[0052] The general commercially available alumina ceramic stent also has the problem of blackening of the silver-plated layer, and its aging characteristics are comparable to samples made of traditional copper-silver-plated / PCT stents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com