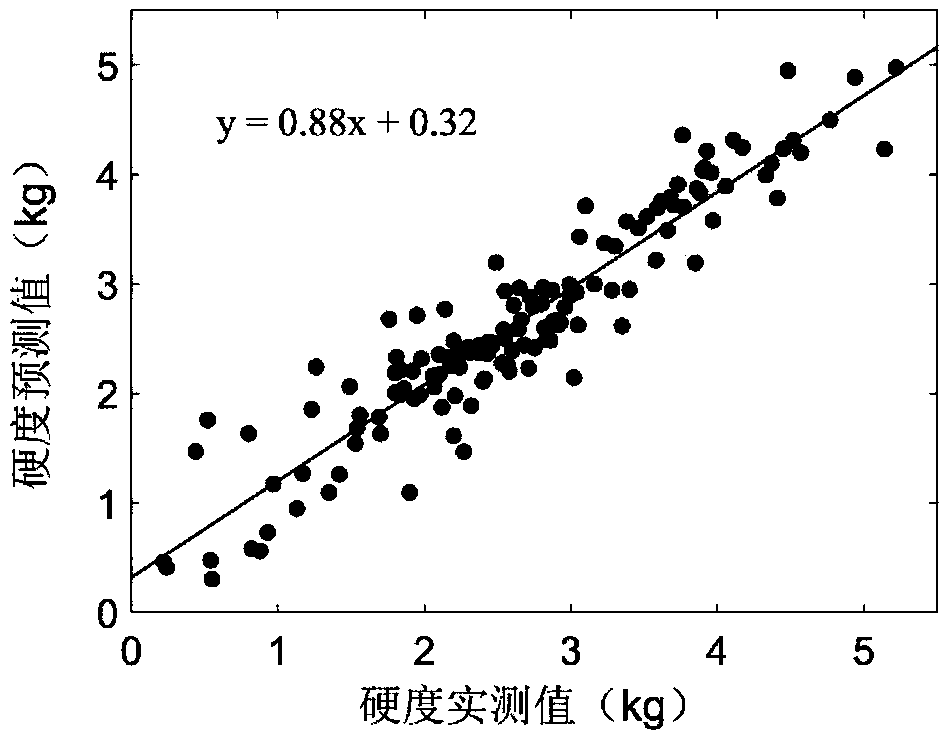

Non-destructive testing method for plum hardness based on visible/near-infrared spectroscopy

A near-infrared spectrum and non-destructive testing technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of large labor expenditure, long modeling cycle, complicated modeling process, etc., and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

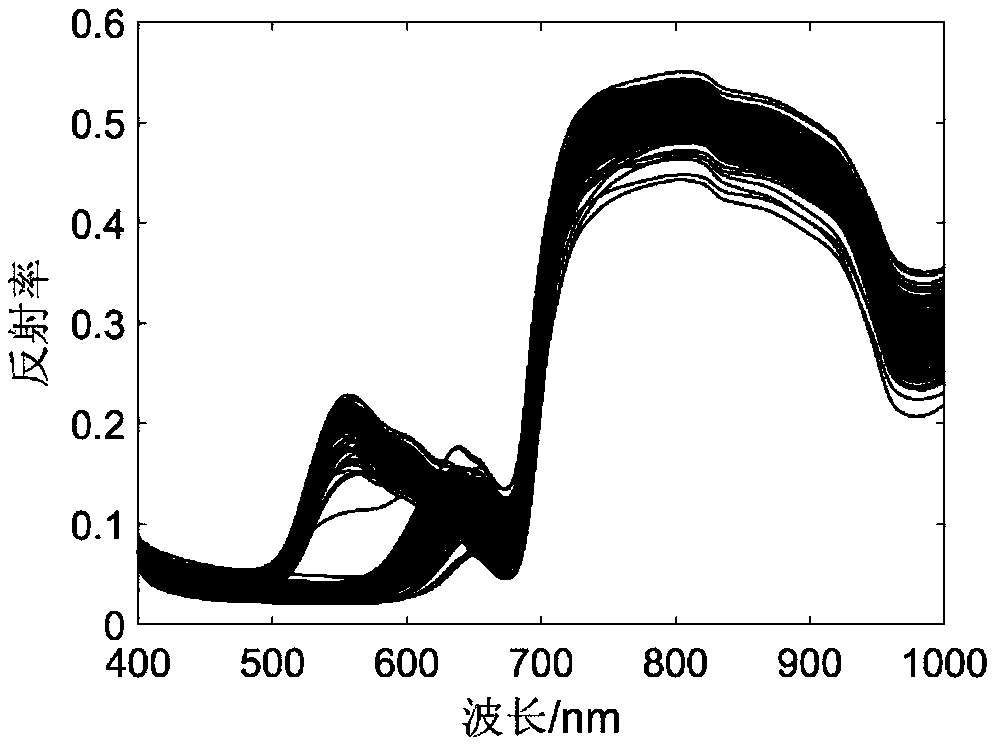

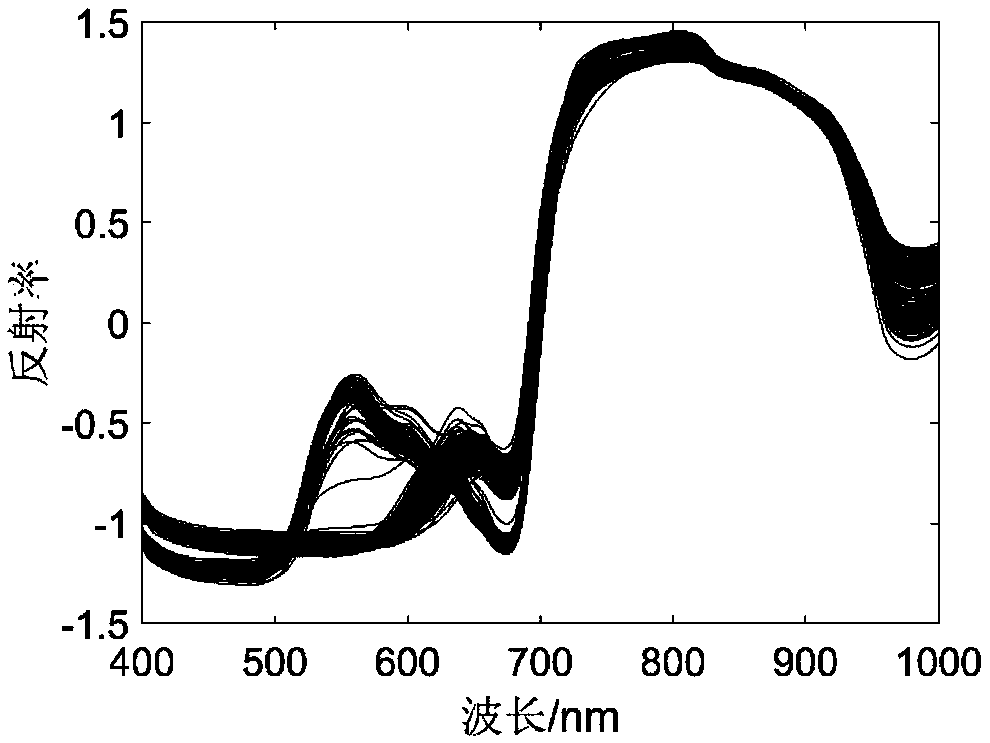

[0031] 1. In this embodiment, a batch of 120 uniformly sized and intact red plums and 60 green plums were selected in the local Wal-Mart supermarket, a total of 180 plum samples; all samples were numbered in sequence, and the hyperspectral image acquisition system was used to collect the plum samples. Hyperspectral image, where the exposure time of the CCD camera is 12.6ms, the distance between the camera lens and the sample is 40cm, and the moving speed of the electric translation stage is 1.35cm / s;

[0032] The image acquisition process is controlled by Spectral SENS (Spectral Imaging Ltd., Finland) software, the spectral range is 400-1000nm, and there are 256 bands in this range;

[0033] Black and white correction is performed on the hyperspectral image of the plum sample collected, that is, under the same system conditions as the sample collection, first scan the standard white calibration plate to obtain a full white calibration image W; then, cover the camera lens cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com