Method for testing fracture property of polypropylene fiber cement stabilized gravel

A technology of cement-stabilized crushed stone and polypropylene fiber, which is applied in the direction of applying stable bending force to test material strength, strength characteristics, preparation of test samples, etc. The accuracy and reliability of the results, the inability to calculate the fracture energy, etc., achieve the effect of small external influencing factors, high accuracy and reliability, and reduced production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, objectives, and effects of the invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0041] This embodiment proposes the fracture performance test method of polypropylene fiber cement stabilized gravel, comprising the following steps:

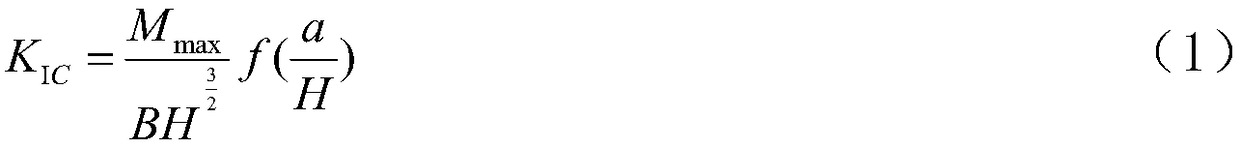

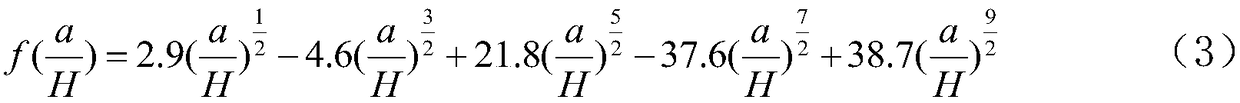

[0042] Step 1: Proportion test specimen

[0043] Proportion the middle beam test piece whose size is 100mm×100mm×515mm, the relative depth of the cutout of the test piece is a 0 / h adopts 0.2m, that is, the incision depth is 20mm, and the mixing ratio PPS00 and PPS06 are respectively formed into 4 groups, and each group has 6 test pieces, which are used to test the fracture parameters of 14 days, 28 days, 60 days, and 90 days respectively. Each of PPS04-5, PPS08-5, PPS10-5, PPS06-4, PPS06-6 and PPS06-7 is molded into one group, with 6 specimens in each group, used to test its 60-day fracture parameters, 6 specimens in each grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com