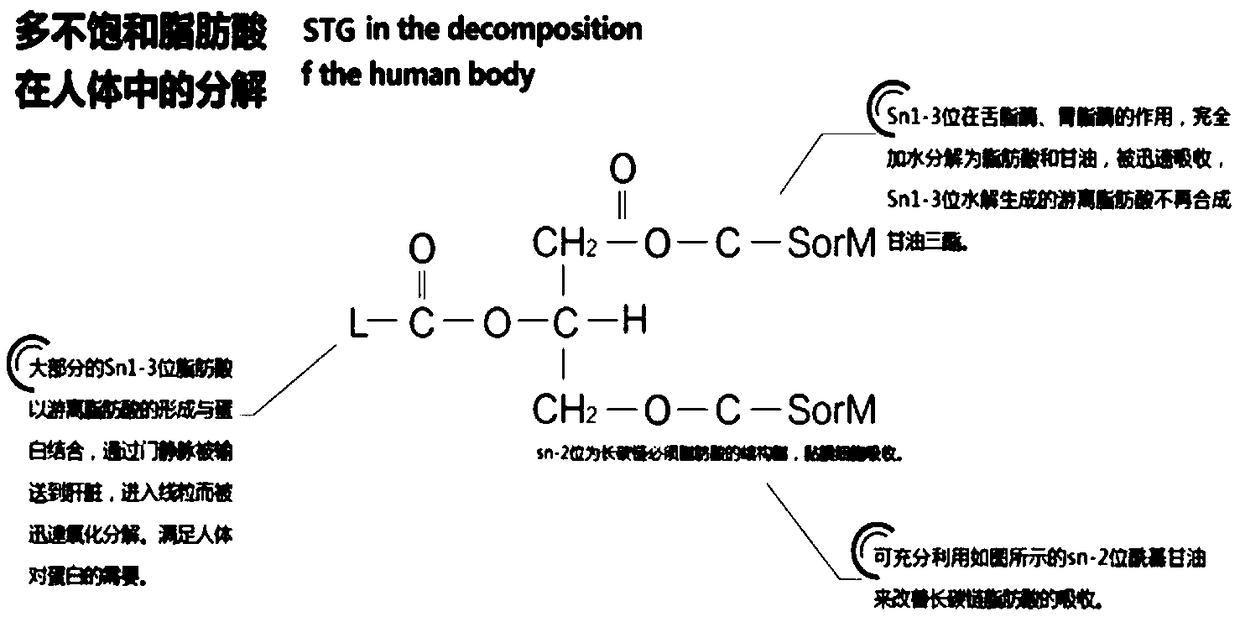

Preparation method of lipid with structure of polyunsaturated fatty acids

A technology of unsaturated fatty acids and structural lipids, applied in the biological field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 The purifying borage oil (the weight content of r-linolenic acid is 20%) of the refined fish oil 29 weight parts of 55 weight parts, the ingot maple seed oil of 6 weight parts, the pine nut oil of 10 weight parts (Pinoline acid) and 6 parts by weight of immobilized lipase 435 were reacted in a closed container under a vacuum condition of 50 Pa, a reaction temperature of 55° C., and a reaction time of 20 hours to terminate the reaction. Entering the refining process, after the reaction product rises close to 120°C and 160°C dry steam is mixed with flash evaporation, the distillation realizes the deacidification, deodorization and passivation of enzyme activity, the flash vacuum is 100Pa, cooling, fine filtration of polyunsaturated fatty acid structured lipids.

Embodiment 2

[0047] Embodiment 2 with 3 parts by weight (the content of reduced fish oil EPA and DHA is 65%), the borage oil of 55 parts by weight (the r-linolenic acid weight content is 87%), the pine nut oil (Pinolar) of 15 parts by weight The weight content of acid is 17%) and 10 weight parts of RM, IM lipase in ultrasonic packed column reaction closed-loop 46 hours, obtain reaction product, then through vacuum 100-200Pa, steam temperature 190 ℃, flash evaporation, deodorization, Inactivate the enzyme activity, cool down to 60°C, add 0.2‰ antioxidant, mix and homogenize, and fill the finished product.

Embodiment 3

[0048] Embodiment 3 The polyene fish oil (the weight content of EPA and DHA is greater than 75%) of 15 weight parts, the evening primrose oil (the weight content of r-linolenic acid is 9%) of 77 weight parts, the pine nut oil of 8 weight parts (the weight content of pinolenic acid is 17%) and the 435 lipases of 8 weight parts, in the supersonic bed layer reactor closed-circuit circulation reaction 28 hours, terminate reaction and enter flashing procedure after fine filtration of product, before flashing, The oil product is first heated to 120°C, and then deodorized and inactivated by 180°C dry steam under a vacuum of 100-200Pa. The finished product is cooled to 60°C, and oil-soluble VE0.2‰ is added, mixed homogeneously, and the finished product can be packed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com