Yellow giner saponin industrial sewage treating method and comprehensive utilization

A technology for industrial wastewater and treatment methods, applied in heating water/sewage treatment, application, agriculture, etc., can solve the problems of insufficient comprehensive utilization of resources, no consideration of acid recovery, etc., to increase saponin yield and obvious biological activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

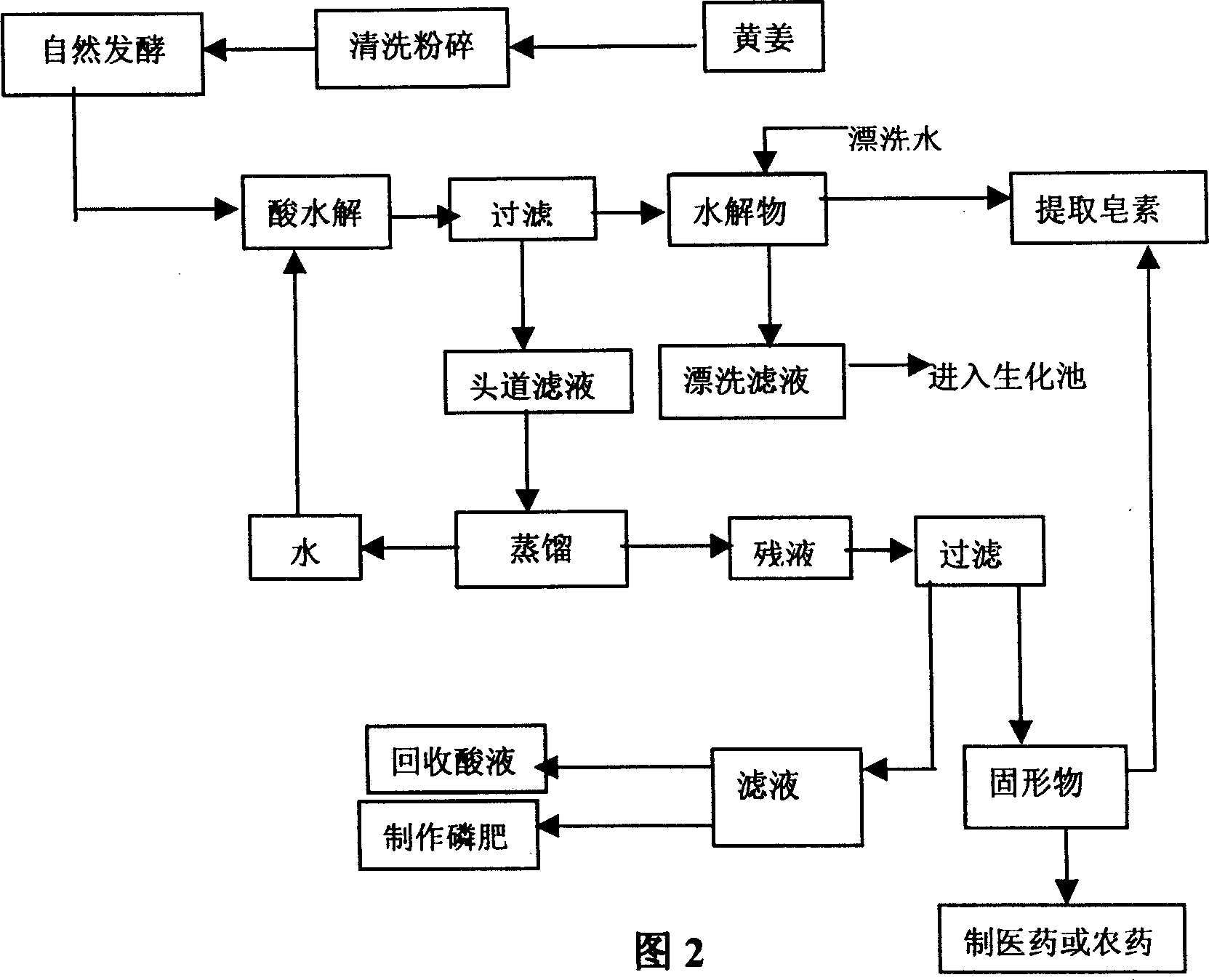

Image

Examples

Embodiment 1

[0018] Weigh 200g of fresh turmeric (measure water content 63.10%) and add 200ml of water, and grind into a fine slurry. Add 0.3 g of α-amylase, raise the temperature to 85-90° C. for 0.5 h, and keep stirring for 1 hour. Lower the temperature to 60°C, add 0.5 g of glucoamylase, adjust the pH to 3.8-4.0, and keep stirring for 1 hour. After the enzyme was inactivated at 100°C under normal pressure for 5 minutes, it was first naturally filtered, and then press-filtered to obtain 130ml of sugar solution with a sugar content of 11.5. The filter residue was added with 200ml of water and 50ml of concentrated hydrochloric acid, hydrolyzed at normal pressure for 6 hours, and filtered under reduced pressure to obtain 430ml of filtrate (1), with a sugar content of 13.5. The filter residue was rinsed with 785ml of water to about pH=6.5, dried, and the weight of the dried hydrolyzate was weighed to be 13.9866g.

[0019] Get 400ml of filtrate (1), and distill it under normal pressure: whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com