Zirconium-containing re-sintered electrically-fused mullite brick and preparation method thereof

A technology for fused mullite and mullite bricks, which is applied in the field of zirconium-containing re-sintered fused mullite bricks and its preparation, can solve problems such as environmental impacts, and achieve molding performance, high product strength, and preparation methods simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-20

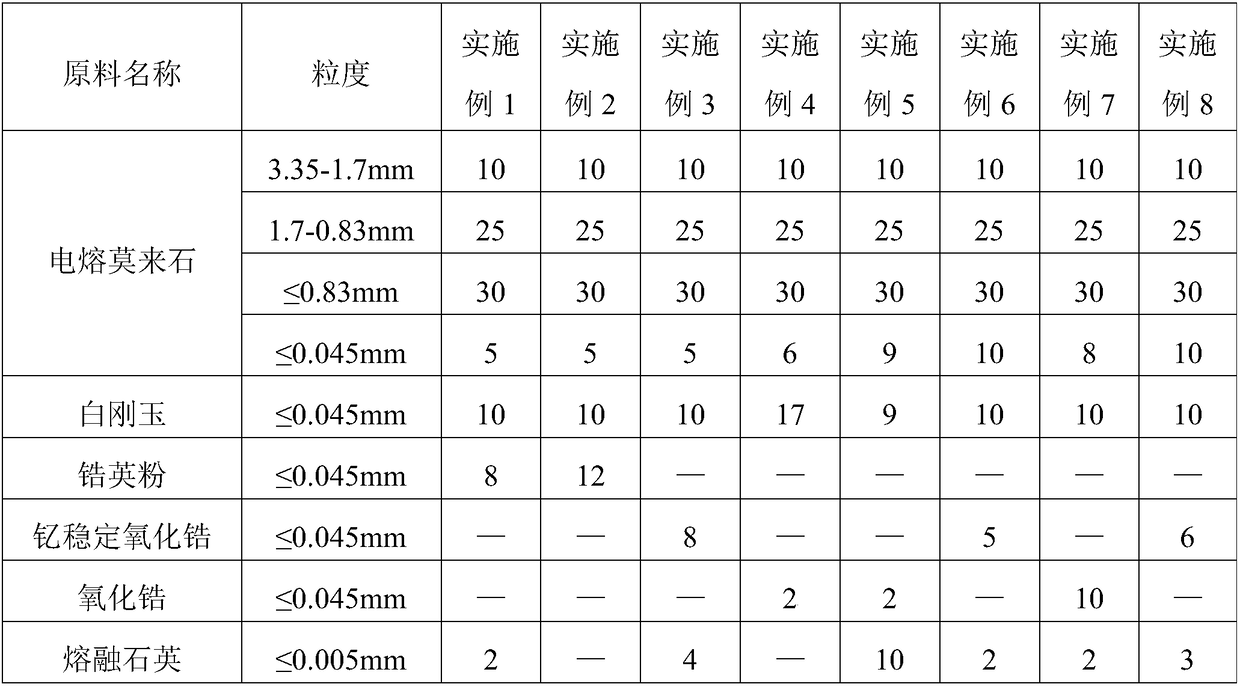

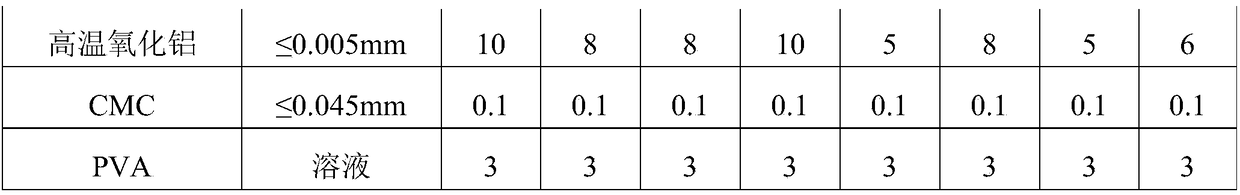

[0033] The types of raw materials, particle size specifications and parts by weight of the zirconium-containing re-sintered fused mullite bricks are as follows:

[0034] Table 1

[0035]

[0036]

[0037] Table 2

[0038]

[0039] table 3

[0040]

[0041]

[0042] The preparation method of the 1-16 zirconium-containing re-sintered fused mullite brick comprises the following steps:

[0043] (1) Fused mullite fine powder, zirconium-containing material fine powder, Al 2 o 3 Micropowder, SiO 2 Mix the fine powder and solid binder fine powder evenly to obtain premixed fine powder;

[0044] (2) Semi-dry mixing: first put the fused mullite particles with a particle size > 0.1mm into the mixer for mixing, then add the liquid binder and mix evenly, then add the premixed fine powder obtained in step (1) , mixed for 10-20min to prepare a semi-dry mud material, and the material was trapped for 4-5h;

[0045] (3) Machine pressing or isostatic pressing, drying, drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com