Novel pull ring material suitable for laser processing and preparation method of novel pull ring material

A new type of laser technology, applied to epoxy resin coatings, devices for coating liquid on the surface, coatings, etc., can solve problems such as blurred patterns or characters, no anti-counterfeiting function, and decreased yield strength, and achieve production Low cost, avoid excessive curing speed, prevent the effect of yield strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

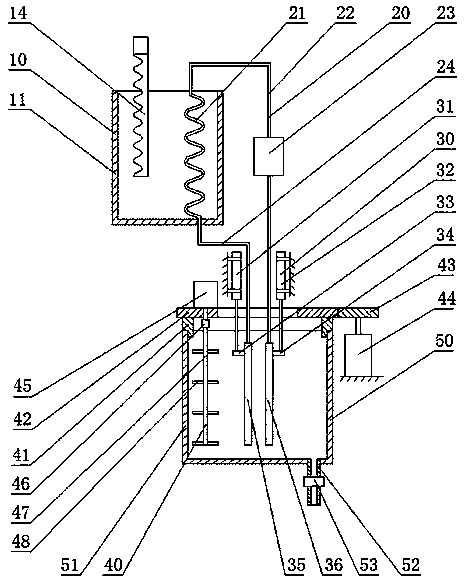

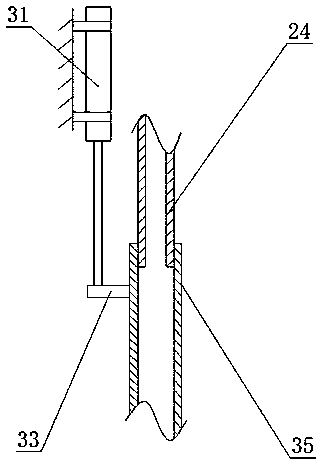

Image

Examples

Embodiment 1

[0032]The high temperature resistant inner coating of the present embodiment comprises the following raw materials in parts by weight: 40 parts of epoxy resin, 11 parts of amino resin, 2 parts of high temperature resistant organic pigment, 16 parts of aromatic hydrocarbon solvent, 10 parts of ethylene glycol monobutyl ether, 3 parts of n-butanol, 10 parts of propylene glycol methyl ether acetate.

[0033] The epoxy outer coating comprises the following raw materials in parts by weight: 25 parts of ethylene glycol monobutyl ether, 5 parts of dibasic ester mixture, 15 parts of propylene glycol methyl ether acetate, 1 part of n-butanol, and 15 parts of aromatic hydrocarbon solvent , 8 parts of nano graphite powder.

[0034] The passivation stock solution includes the following raw materials in parts by weight: 0.1 part of hydrofluoric acid, 20 parts of nitric acid, and 10 parts of trivalent chromium.

[0035] A method for preparing a new pull ring material suitable for laser pro...

Embodiment 2

[0038] The high-temperature-resistant inner coating of this embodiment includes the following raw materials in parts by weight: 42 parts of epoxy resin, 12 parts of amino resin, 1 part of high-temperature-resistant organic pigment, 0.1 part of dispersant, 18 parts of aromatic hydrocarbon solvent, ethylene glycol alone 15 parts of butyl ether, 5 parts of n-butanol, and 16 parts of propylene glycol methyl ether acetate.

[0039] The epoxy outer coating comprises the following raw materials in parts by weight: 18 parts of ethylene glycol monobutyl ether, 8 parts of dibasic ester mixture, 20 parts of propylene glycol methyl ether acetate, 3 parts of n-butanol, and 18 parts of aromatic hydrocarbon solvent , 7 parts of nano graphite powder.

[0040] The passivation stock solution includes the following raw materials in parts by weight: 0.8 parts of hydrofluoric acid, 25 parts of nitric acid, and 4 parts of trivalent chromium.

[0041] A method for preparing a new pull ring material...

Embodiment 3

[0044] The high temperature resistant inner coating of the present embodiment comprises the following raw materials in parts by weight: 46 parts of epoxy resin, 13 parts of amino resin, 5 parts of high temperature resistant organic pigment, 0.5 part of dispersant, 15 parts of aromatic hydrocarbon solvent, ethylene glycol mono 14 parts of butyl ether, 2 parts of n-butanol, 13 parts of propylene glycol methyl ether acetate.

[0045] The epoxy outer coating comprises the following raw materials in parts by weight: 15 parts of ethylene glycol monobutyl ether, 7 parts of dibasic ester mixture, 18 parts of propylene glycol methyl ether acetate, 4 parts of n-butanol, 20 parts of aromatic hydrocarbon solvent , 6 parts of nano graphite powder.

[0046] The passivation stock solution includes the following raw materials in parts by weight: 0.8 parts of hydrofluoric acid, 27 parts of nitric acid, and 5 parts of trivalent chromium.

[0047] A method for preparing a new pull ring material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com