Microfluidic free flow paper chromatographic array spray mass spectrometry device

A technology of microfluidics and paper chromatography, which is applied in the field of chromatography-mass spectrometry, can solve the problems of low separation efficiency and time-consuming, and achieve the effects of improving separation efficiency, saving space, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

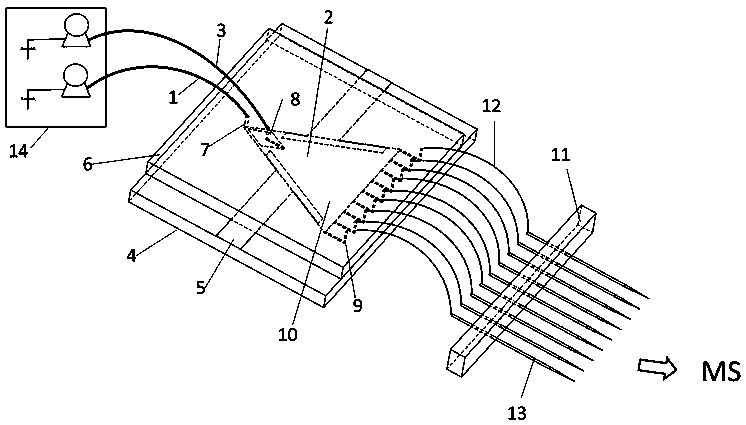

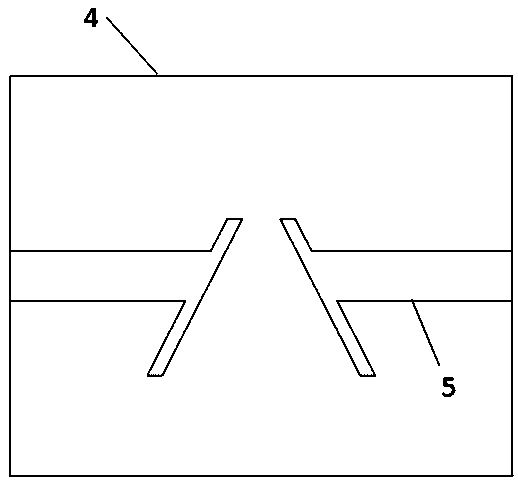

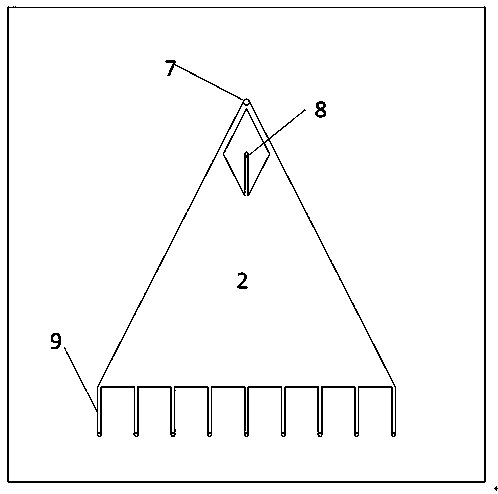

[0039] Such as figure 1 , As shown in 2, 3, the microfluidic free paper chromatography array spray mass spectrometry device includes a microfluidic control device 14, a microfluidic free flow paper chromatographic separation device that is a microfluidic carrier plate 4, a microfluidic cover plate 6, Paper stationary phase 10, and array spray component 11, mass spectrometry component. In this embodiment, the paper stationary phase 10 is placed in the separation cavity 2 formed by the microfluidic carrier plate 4 and the microfluidic cover plate 6 to ensure that the device is sealed. The buffer or mobile phase enters the separation chamber 2 through the first pipe 1 through the microfluidic channel 7, and the sample enters the separation cavity 2 through the second pipe 3 through the sample channel 8; in this embodiment, microfluidic control is used The device 14 controls the sample loading and the flow control of the buffer or mobile phase. The microfluidic control device 14 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com