Preparation method of modified mixed basalt fiber doped asphalt

A basalt fiber and mixed fiber technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor asphalt compatibility, uneven segregation, environmental and human hazards, etc., and achieve superior tensile strength. Strength, saving manpower and material resources, less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

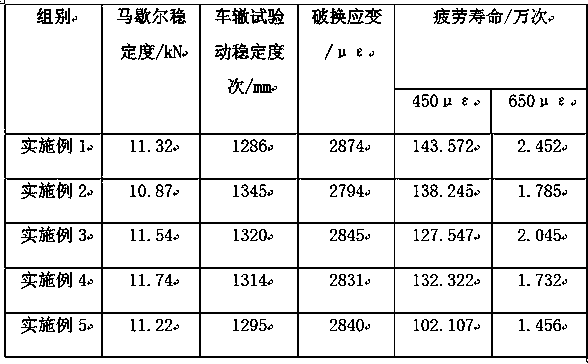

Examples

Embodiment 1

[0026] (1) Soak 2.6 parts by mass of 10-20mm basalt fibers and 0.7 parts by mass of ceramic fibers of 15-30mm in excess sodium hydroxide for 30 minutes, drain the sodium hydroxide, and immediately add 0.7 parts by mass of hydroxyethyl Sodium sulfonate and 0.2 parts by mass of dilauroyl peroxide were stirred at 90°C and 1.5Mpa for 45min at 600r / min to obtain a modified mixed fiber;

[0027] (2) Heat 100 parts by mass of base asphalt to 165°C, add 2 parts by mass of styrene-butadiene rubber, 5 parts by mass of SBS, modified mixed fiber, 1 part by mass of kaolin, 3 parts by mass of Diatomite, 7 parts by mass of polydimethylsiloxane, 2 parts by mass of stearic acid, and 0.9 parts by mass of benzoin were stirred at 1000 r / min for 18 minutes to obtain a modified mixed basalt fiber pitch.

Embodiment 2

[0029] (1) Soak 1.7 parts by mass of 10-20mm basalt fibers and 1.1 parts by mass of ceramic fibers of 15-30mm in excess sodium hydroxide for 35 minutes, drain the sodium hydroxide, and immediately add 1.5 parts by mass of hydroxyethyl Sodium sulfonate and 0.4 parts by mass of dilauroyl peroxide were stirred at 95°C and 1.2Mpa for 60min at 800r / min to obtain a modified mixed fiber;

[0030] (2) Heat 100 parts by mass of base asphalt to 175°C, add 1 part by mass of styrene-butadiene rubber, 5.5 parts by mass of SBS, modified mixed fiber, 2 parts by mass of bentonite, 4 parts by mass of Limestone and 2 parts by mass of montmorillonite, 8 parts by mass of polydimethylsiloxane, 1 part by mass of stearic acid, and 1.1 parts by mass of benzoin dimethyl ether were stirred at 1100r / min for 22 min to obtain improved Sexual mixed basalt fiber asphalt.

Embodiment 3

[0032] (1) Soak 3.3 parts by mass of 10-20mm basalt fibers and 1.57 parts by mass of ceramic fibers of 15-30mm in excess sodium hydroxide for 25 minutes, drain the sodium hydroxide, and immediately add 1.0 parts by mass of hydroxyethyl Sodium sulfonate and 0.3 parts by mass of dilauroyl peroxide were stirred at 80°C and 1Mpa for 55min at 500r / min to obtain a modified mixed fiber;

[0033] (2) Heat 100 parts by mass of base asphalt to 170°C, add 1 part by mass of styrene-butadiene rubber, 4 parts by mass of SBS, modified mixed fiber, 3 parts by mass of kaolin, and 3 parts by mass of Limestone, 5 parts by mass of polydimethylsiloxane, 1.5 parts by mass of stearic acid, and 1.3 parts by mass of benzoin ether were stirred at 1200 r / min for 27 minutes to obtain a modified mixed basalt fiber pitch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com