High-purity cordierite-combined mullite material and preparation method thereof

A technology of purity cordierite and mullite, which is applied in the field of high-purity cordierite-combined mullite material and its preparation field, and achieves the effects of avoiding unstable product performance, long service life and low thermal expansion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

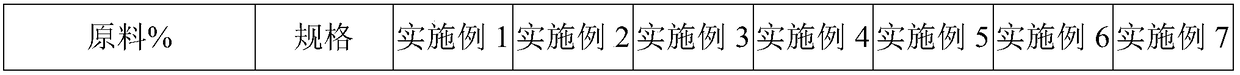

[0034] The present invention will be further described below.

[0035] Machine press molding:

[0036] Raw materials: 0.044mm high-purity synthetic cordierite, 0.1-1mm synthetic Morco, magnesium lignosulfonate stock solution, carboxymethyl cellulose solution, polyvinyl alcohol solution;

[0037] Preparation:

[0038] (1) Mixing: add synthetic Morco and compound organic additives into the mixer, add an appropriate amount of water and stir evenly, add the synthetic cordierite fine powder into the mixer, and mix evenly to obtain a machine-pressed mud material ;

[0039] (2) Trapped material: The machine-pressed mud material is put into a sealed woven bag and trapped for more than 24 hours;

[0040] (3) Forming: machine press forming;

[0041] (4) Drying: put the formed bricks into a far-infrared drying oven for drying, the drying temperature is 120°C, and the temperature is kept for 24h;

[0042] (5) Firing: the firing temperature is 1350°C, and the temperature is kept for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com