Rubber product double-density one-off injection molding production system and production process thereof

A technology of injection molding and rubber products, applied to hollow objects, other household appliances, tires, etc., can solve the problems of time-consuming, high cost, energy consumption, etc., and achieve the effect of reducing energy consumption, reducing scrap rate, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

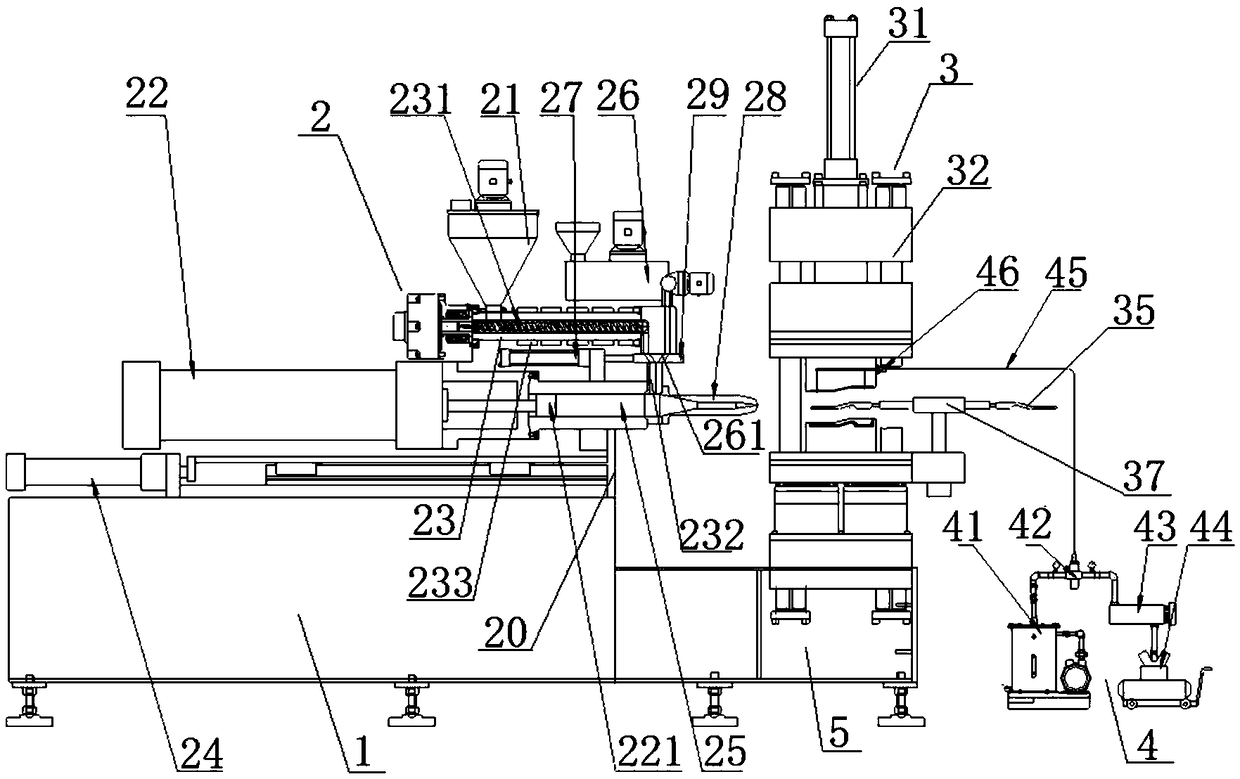

[0049] The double-density one-time injection molding production system for rubber products of this embodiment, such as figure 1 As shown, it includes an injection machine base 1, a die vulcanization base 5, an injection device 2 and a die vulcanization device 3 respectively fixed on both, and a hollow device 4 beside the die vulcanization base 5. The die The vulcanizing device 3 includes two mold inner cores with the same shape and different specifications. The two inner cores are successively placed into the mold. The injection device 2 injects two plasticized rubber materials with different densities corresponding to different mold inner cores into In the mold of the compression molding vulcanization device 3, the hollow device 4 can pass high-pressure gas into the plasticized rubber material in the mold of the compression molding vulcanization device 3 to form a hollow cavity of high-pressure gas, so that it has the high-pressure conditions required for vulcanization , the ...

Embodiment 2

[0052] The double-density one-time injection molding production system for rubber products in this embodiment has the same basic structure as that in Embodiment 1, except that the injection device 2 includes a feeding hopper 21, an injection cylinder 22, a plasticizing injection screw barrel 23, and a moving cylinder for an injection seat. 24. Pre-injection material cavity 25, continuous foaming machine 26, material switching cylinder 27, injection head 28 and material switching switching valve 29; the feeding hopper 21 communicates with the beginning of the plasticizing injection screw barrel 23, The barrel 23 is fixed on the side of the cylinder barrel of the injection cylinder 22; the plasticizing injection barrel 23 and the discharge port of the continuous foaming machine 26 communicate with the pre-injection chamber 25 through the first feeding pipe 232 and the second feeding pipe 261 respectively. , the material switching conversion valve 29 is connected with the piston r...

Embodiment 3

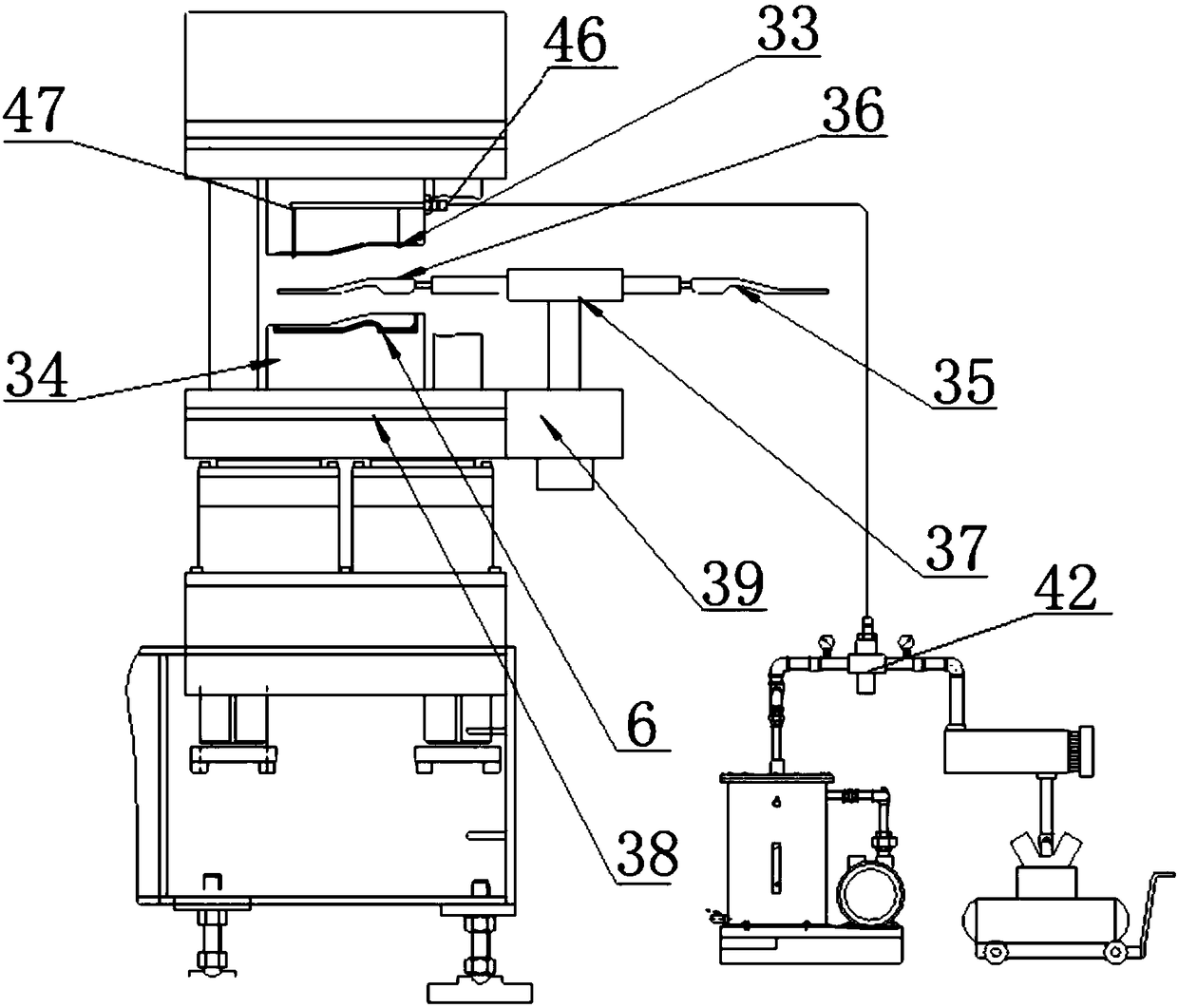

[0070] The double-density one-time injection molding production system for rubber products of this embodiment has the same basic structure as that of Embodiment 2, and the improvements are as follows: figure 2 As shown, mold inner core one 35 and mold inner core two 36 have the same shape as the sole, but the specifications are different. The hollow device 4 also includes an electric control three-way valve 42, an air heater 43 and a pipe joint 46; the high-pressure air compressor 44 is connected with the electric control three-way valve 42 after being passed into the air heater 43 through the air pipe, and the vacuum exhaust station 41 is connected with the electric control three-way valve 42 through the air pipe, and the high-pressure air pipe 45 and the electric control three-way valve 42 connection, the three are respectively connected with the three passages of the electric control three-way valve 42; the other end of the high-pressure air pipe 45 communicates with the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com