Lithium-supplementing porous silicon monoxide negative electrode material for lithium ion batteries and preparation method thereof

A lithium-ion battery and silicon monoxide technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as difficult performance, complex process, and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

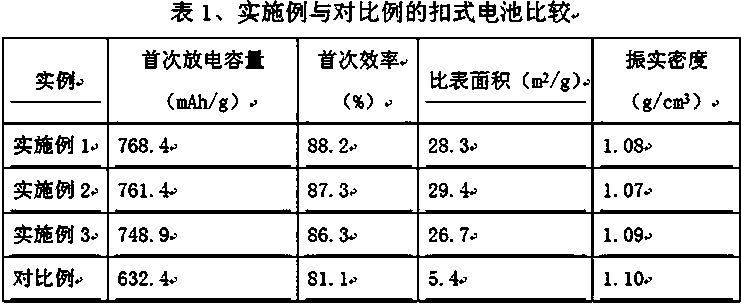

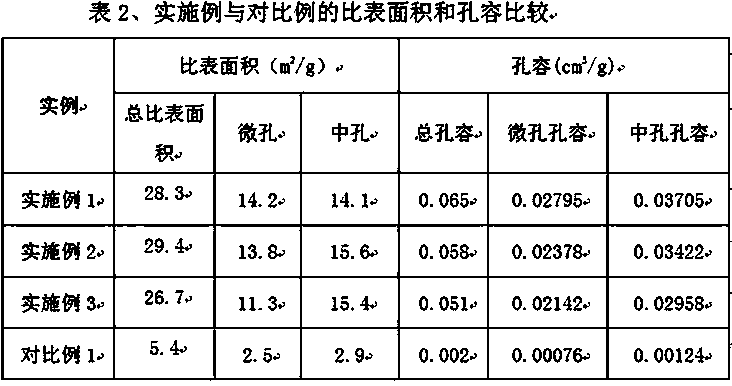

Embodiment 1

[0025] Mix 100g of silicon monoxide (particle size 5μm) and 5g of nano-nickel (particle size 200nm) into a ball mill, the diameter of the ball is 5mm, the ball-to-material ratio is 8:1, the ball milling speed is 500 rpm, and the ball milling is 24h, to get Silicon monoxide alloy material A; then place silicon monoxide alloy material A in a vacuum heat treatment furnace with a vacuum degree of 0.05 Pa; then heat at a temperature of 1500°C and keep it warm for 5 hours to obtain porous monoxide Silicon material B; naturally cool the porous silicon monoxide material B to 600°C, pass through methane gas and ammonia gas (volume ratio: 100:5), and keep at this temperature for 3 hours, and naturally cool down to room temperature to obtain porous silicon monoxide Silicon composite material C; then weigh 100g of porous silicon monoxide composite material C and 0.5g of inert lithium powder into a ball mill, and ball mill for 6 hours under an argon atmosphere to obtain lithium-replenishing...

Embodiment 2

[0027] Add 100g of silicon monoxide and 1g of nano-aluminum (particle size 100nm) into a ball mill with a ball diameter of 4mm, a ball-to-material ratio of 7:1, a ball milling speed of 500 rpm, and ball milling for 48 hours to obtain a silicon monoxide alloy material A; Afterwards, the silicon monoxide alloy material A is placed in a vacuum heat treatment furnace, and the vacuum degree is kept between 0.1Pa; then heated, and the temperature is kept between 1300°C and kept for 0.1h to obtain a porous silicon monoxide material B; the porous Silicon monoxide material B was naturally cooled to 800°C, acetylene gas and ammonia gas (volume ratio: 100:1) were introduced into it, and kept at this temperature for 1 hour, and then naturally cooled to room temperature to obtain porous silicon monoxide composite material C; Take 100g of porous silicon monoxide composite material C and 0.1g of inert lithium powder and add them to a ball mill, and ball mill for 1 hour under an argon atmosphe...

Embodiment 3

[0029] Add 100g of silicon monoxide and 10g of nano-silver (particle size 500nm) into a ball mill with a ball diameter of 6mm, a ball-to-material ratio of 10:1, a ball milling speed of 600 rpm, and ball milling for 12 hours to obtain a silicon monoxide alloy material A; Then place silicon monoxide alloy material A in a vacuum heat treatment furnace, keep the vacuum degree between 1Pa; then heat, keep the temperature between 1000°C, and keep it warm for 10h to obtain porous silicon monoxide material B; The temperature of silicon material B is naturally cooled to 800°C, and ethane gas and ammonia gas (volume ratio: 100:10) are passed through, and kept at this temperature for 6 hours, and the temperature is naturally cooled to room temperature to obtain porous silicon monoxide composite material C; Add 100g of porous silicon monoxide composite material C and 1g of inert lithium powder into a ball mill, and ball mill for 12 hours under an inert atmosphere to obtain lithium-replenis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com